Analysis method for determining titanium, vanadium, tungsten, manganese and silicon in K25 chromium-base high temperature alloy

A technology of superalloy, titanium vanadium, applied in the field of alloy constant element analysis, can solve the problems of incomplete dissolution, long analysis period, long time for dissolving samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

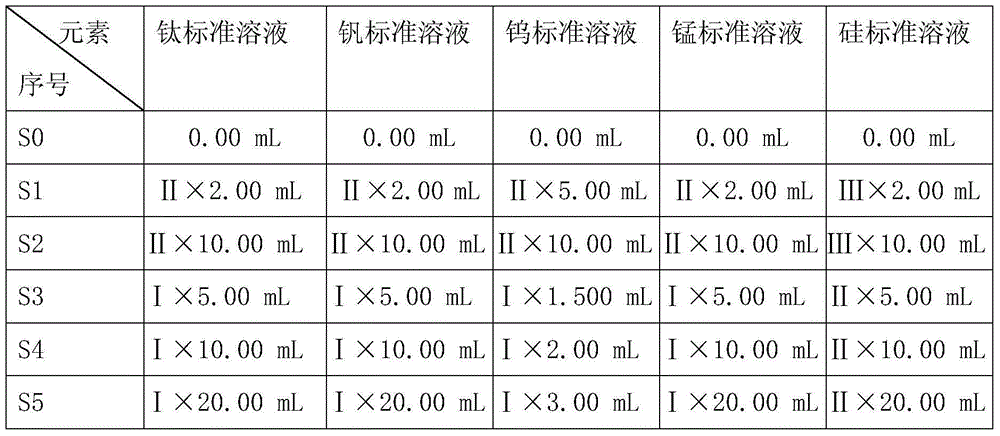

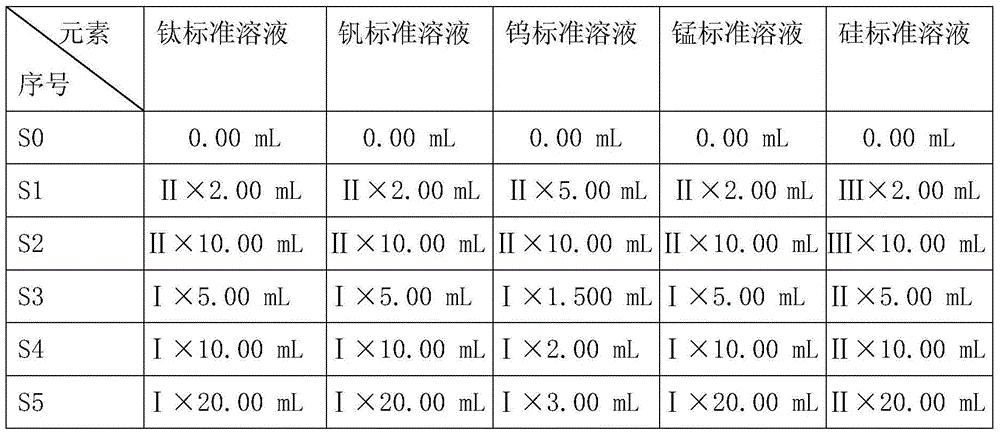

[0072] To measure the content of titanium, vanadium, tungsten, manganese and silicon in K25 chromium-based superalloy, an inductively coupled plasma emission spectrometer is used. The working conditions and analysis lines of the instrument are as follows: high frequency frequency: 40.68MHz; incident power: 0.95~1.1Kw ;Reflected power: <15W; Cooling air flow: 12~20L / min; Sheath air flow: 0.1~0.6L / min; Sample lift: 1.0~1.5ml / min; Integration time: 1~10s; : Titanium 334.941nm; Vanadium 292.402nm; Tungsten 207.911nm; Manganese 257.610nm; Silicon 288.158nm or 251.611nm;

[0073] (1) The reagents used in the determination process are as follows:

[0074] (1.1) Hydrochloric acid, ρ1.19g / mL; superior grade;

[0075] (1.2) Nitric acid, ρ1.42g / mL; superior grade;

[0076] (1.3) Sulfuric acid, ρ1.84g / mL; superior grade;

[0077] (1.4) Hydrofluoric acid, ρ1.15g / mL, superior grade;

[0078] (1.5) sulfuric acid, 1+1;

[0079] (1.6) Nitric acid, 1+1;

Embodiment 2

[0120] To measure the content of titanium, vanadium, tungsten, manganese and silicon in K25 chromium-based superalloy, an inductively coupled plasma emission spectrometer is used. The working conditions and analysis lines of the instrument are as follows: high frequency frequency: 40.68MHz; incident power: 0.95~1.1Kw ;Reflected power: <15W; Cooling air flow: 12~20L / min; Sheath air flow: 0.1~0.6L / min; Sample lift: 1.0~1.5ml / min; Integration time: 1~10s; : Titanium 334.941nm; Vanadium 292.402nm; Tungsten 207.911nm; Manganese 257.610nm; Silicon 288.158nm or 251.611nm;

[0121] (1) The reagents used in the determination process are as follows:

[0122] (1.1) Hydrochloric acid, ρ1.19g / mL; superior grade;

[0123] (1.2) Nitric acid, ρ1.42g / mL; superior grade;

[0124] (1.3) Sulfuric acid, ρ1.84g / mL; superior grade;

[0125] (1.4) Hydrofluoric acid, ρ1.15g / mL, superior grade;

[0126] (1.5) sulfuric acid, 1+1;

[0127] (1.6) Nitric acid, 1+1;

Embodiment 3

[0162] To measure the content of titanium, vanadium, tungsten, manganese and silicon in K25 chromium-based superalloy, an inductively coupled plasma emission spectrometer is used. The working conditions and analysis lines of the instrument are as follows: high frequency frequency: 40.68MHz; incident power: 0.95~1.1Kw ;Reflected power: <15W; Cooling air flow: 12~20L / min; Sheath air flow: 0.1~0.6L / min; Sample lift: 1.0~1.5ml / min; Integration time: 1~10s; : Titanium 334.941nm; Vanadium 292.402nm; Tungsten 207.911nm; Manganese 257.610nm; Silicon 288.158nm or 251.611nm;

[0163] (1) The reagents used in the determination process are as follows:

[0164] (1.1) Hydrochloric acid, ρ1.19g / mL; superior grade;

[0165] (1.2) Nitric acid, ρ1.42g / mL; superior grade;

[0166] (1.3) Sulfuric acid, ρ1.84g / mL; superior grade;

[0167] (1.4) Hydrofluoric acid, ρ1.15g / mL, superior grade;

[0168] (1.5) sulfuric acid, 1+1;

[0169] (1.6) Nitric acid, 1+1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com