Water-in-oil associated non-crosslinked fracturing fluid concentrating and thickening agent and preparation method thereof and fracturing fluid

An associative, non-cross-linking technology, applied in the field of fracturing fluid, can solve the problems of affecting the application performance of fracturing fluid, insufficient dissolution, uneven mixing, etc., and achieve the increase of physical cross-linking network strength and obvious dissolution time , enhance the sand-carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention also provides a method for preparing the water-in-oil association type non-crosslinked fracturing fluid concentrated thickener, comprising the following steps:

[0062] A) mixing and stirring the dispersed phase, the dispersion medium and the composite emulsifier to obtain a water-in-oil emulsion;

[0063] B) adding a hydrophobic association polymer fracturing fluid thickener to the water-in-oil emulsion, and mixing and stirring to obtain a water-in-oil association type non-crosslinked fracturing fluid concentrated thickener.

[0064] In the present invention, firstly, the dispersed phase, the dispersed medium and the composite emulsifier are mixed and stirred to obtain the water-in-oil emulsion;

[0065] In the present invention, the mixing temperature is 35-70°C, preferably 40-65°C, more preferably 45-60°C; the mixing speed is 300-800rmp, preferably 400-600rmp; the mixing The stirring time is 20-40 minutes.

[0066] After the water-in-oil emuls...

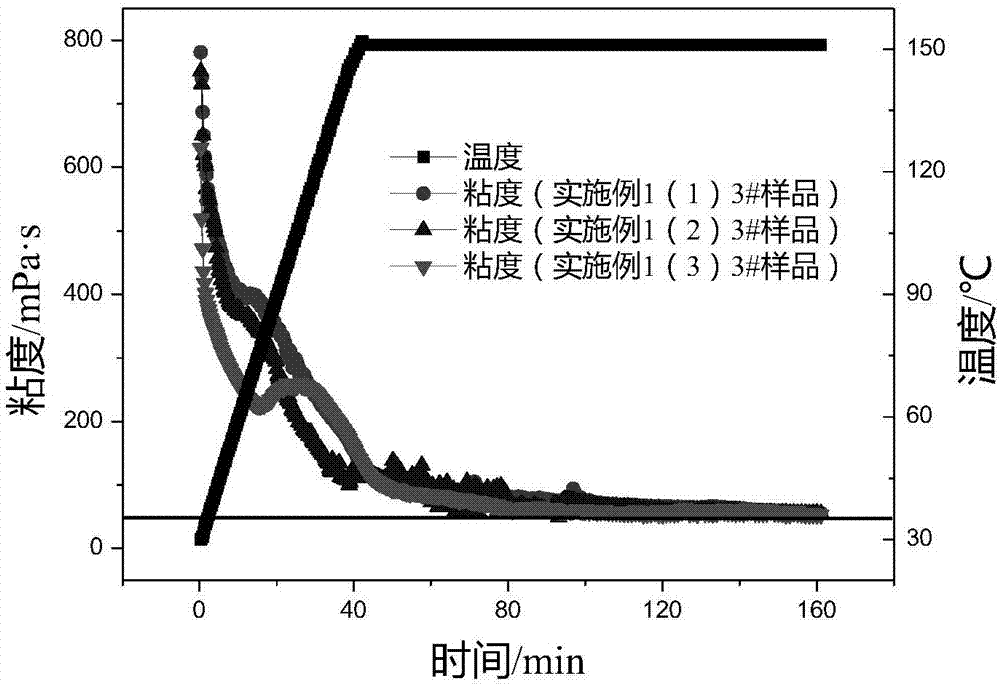

Embodiment 1

[0081] Preparation of water-in-oil (W / O) associative non-crosslinked fracturing fluid concentrated thickener (compound emulsifier is tripolyglycerol diisostearate + stearic acid polyoxyethylene ether SG-6)

[0082] (1) A W / O association type non-crosslinked fracturing fluid concentrated thickener, comprising the following components in mass percentage:

[0083] 0# diesel oil 35.72%, water 35.72%, hydrophobic association type non-crosslinked fracturing fluid thickener (hereinafter referred to as "fracturing fluid thickener") 25%, triglycerol diisostearate 2.85%, Stearic acid polyoxyethylene ether SG-6 0.71%;

[0084] The fracturing fluid thickener is acrylamide / sodium acrylate / N-dodecyl substituted acrylamide copolymer, and the composite emulsifier is tripolyglycerol diisostearate and SG-6 (ratio 4:1), the preparation steps are as follows:

[0085] At 50°C, control the mass ratio of oil to water to 5:5, mix and emulsify 357.2g diesel, 357.2g water, 28.5g tripolyglycerol diiso...

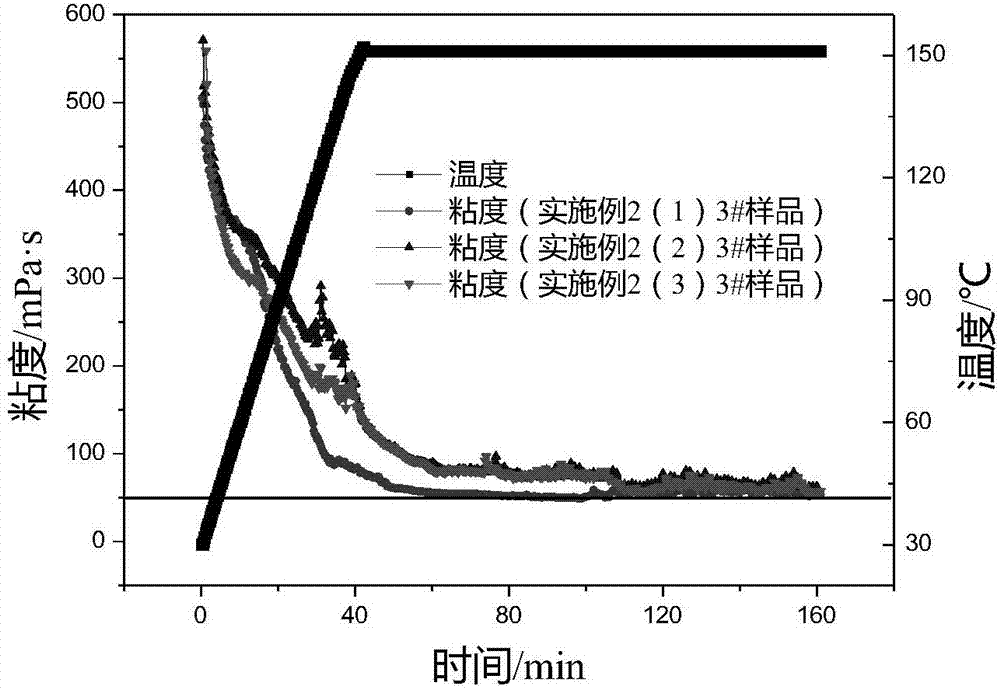

Embodiment 2

[0095] Preparation of water-in-oil (W / O) associative non-crosslinked fracturing fluid concentrated thickener (compound emulsifier is zinc stearate + polyoxyethylene oleate A-105)

[0096] (1) A W / O association type non-crosslinked fracturing fluid concentrated thickener, comprising the following components in mass percentage:

[0097] 0# diesel oil 42.86%, water 28.57%, fracturing fluid thickener 25%, zinc stearate 2.14%, polyoxyethylene oleate A-105 1.43%;

[0098] The fracturing fluid thickener is acrylamide / sodium acrylate / tetradecyl acrylate copolymer, and the composite emulsifier is zinc stearate and A-105 (ratio 3:2), and the preparation steps are as follows :

[0099] At 50°C, control the mass ratio of oil to water to 6:4, mix and emulsify 428.6g diesel, 285.7g water, 21.4g zinc stearate, 14.3g A-105, stir at 600rmp for 30min to form a stable oil Water-in-emulsion, finally add 250g of fracturing fluid thickener, and form a uniform and stable W / O associative non-crossl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com