Heat-resistant and salt-tolerant polymer oil-displacing agent and preparation method thereof

A technology of temperature and salt resistance and polymer, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of high comprehensive water content, poor temperature and salt resistance, and higher requirements for temperature and salt resistance. The effect of enhanced oil recovery, good high temperature resistance, and shortened dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

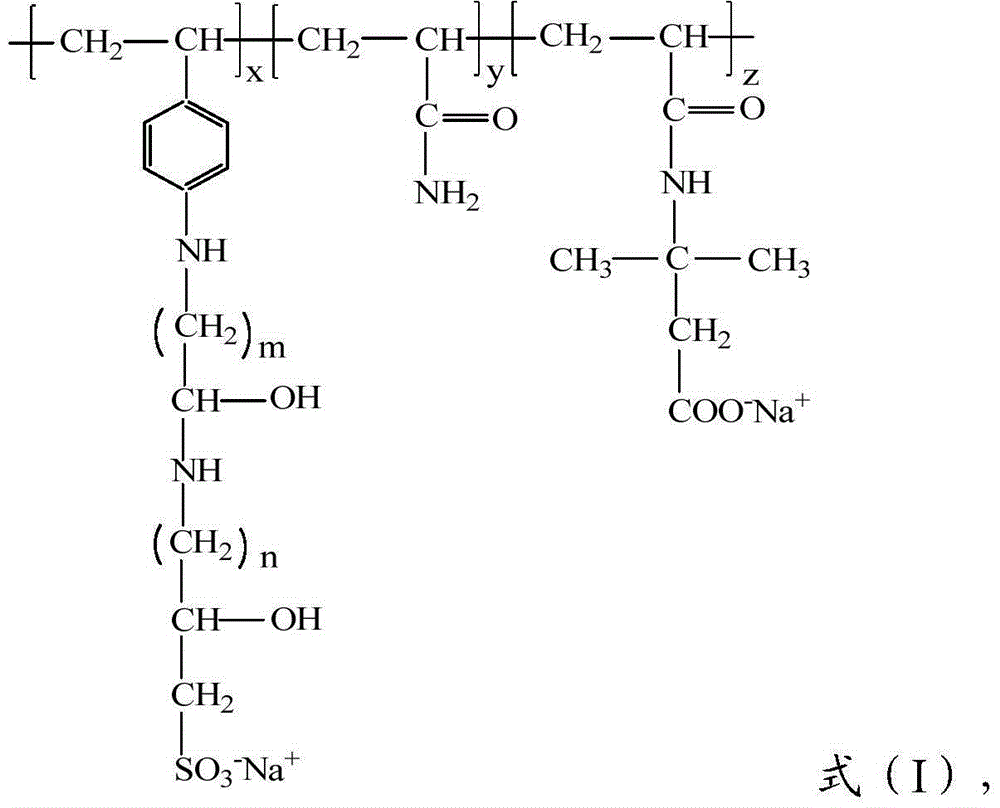

[0033] The present invention also provides a preparation method of a temperature-resistant and salt-resistant polymer oil displacement agent, comprising:

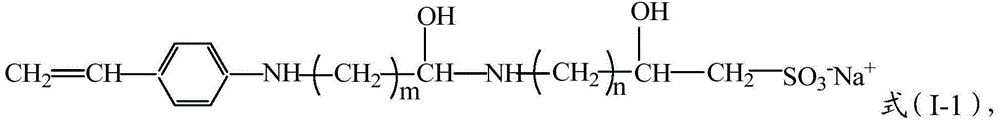

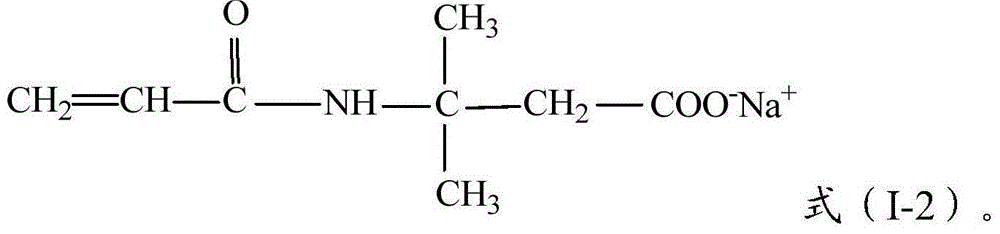

[0034] Mixing and copolymerizing the compound represented by the formula (I-1), acrylamide and the compound represented by the formula (I-2) to obtain a temperature-resistant and salt-resistant polymer oil displacement agent;

[0035]

[0036] Wherein, m is 0-4, n is 1-5;

[0037]

[0038] Wherein, the mass ratio of the compound represented by the formula (I-1), acrylamide and the compound represented by the formula (I-2) is preferably (3-15): (30-70): (20-40) , more preferably (5-12): (35-65): (25-35), most preferably (8-10): (40-60): (28-33).

[0039] Specifically, the present invention preferably prepares the temperature-resistant and salt-resistant polymer oil displacement agent according to the following method:

[0040] 3-1) mixing the compound represented by formula (I-1), acrylamide and the compound represen...

Embodiment 1

[0056] 50 parts by weight of acrylamide, 8.5 parts by weight of sulfonic acid monomers (m=0, n=1) containing phenyl and alcoholic hydroxyl groups, containing 28 parts by weight of the carboxylic acid monomer of the amido group and 500 parts by weight of deionized water are stirred until completely dissolved to obtain a mixed solution;

[0057] Use sodium hydroxide to adjust the pH value of the mixed solution to 9.8, then add 0.05 parts by weight of disodium ethylenediamine tetraacetate, 0.1 parts by weight of urea, and 0.15 parts by weight of a solubilizer to the polymerization bottle in sequence, and stir until it dissolves evenly to obtain adjuvanted agent mixture;

[0058] Control the initial temperature of the mixed liquid system with auxiliary agents at 5°C, pass nitrogen and deoxygenate for 20-30 minutes, add redox-azo water-soluble composite initiators (0.08 parts by weight of ammonium persulfate, 0.04 parts by weight of sodium formaldehyde sulfoxylate) , azobisisobuty...

Embodiment 2

[0065] 50 parts by weight of acrylamide, 8 parts by weight of sulfonic acid monomers (m=1, n=2) containing phenyl and alcoholic hydroxyl groups, containing 35 parts by weight of carboxylic acid monomer of amide group and 700 parts by weight of deionized water are stirred until completely dissolved to obtain a mixed solution;

[0066] Use sodium hydroxide to adjust the pH value of the mixed solution to 8.1, add 0.05 parts by weight of disodium edetate, 0.1 parts by weight of urea, and 0.15 parts by weight of solubilizer to the polymerization bottle in sequence, and stir until it dissolves evenly to obtain the adjuvant of the mixture.

[0067] Control the initial temperature of the mixed liquid system with auxiliary agents at 5°C, pass nitrogen to remove oxygen for 20 to 30 minutes, add redox-azo water-soluble composite initiators (0.08 parts by weight of ammonium persulfate, 0.04 parts by weight of sodium formaldehyde sulfoxylate) , azobisisobutylamidine hydrochloride 0.18 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com