Method for detecting zirconium content in tantalum-cobalt-base alloy in microwave solution sample dissolving manner

A technology of microwave digestion and cobalt-based alloys, which is applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of unsuitable cobalt-based alloy dissolution and measurement, easy formation of precipitates, large spectral interference, etc. problems, to achieve the effects of fast measurement, improved accuracy, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

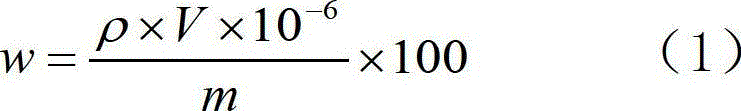

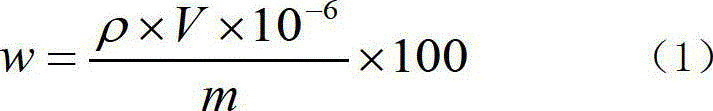

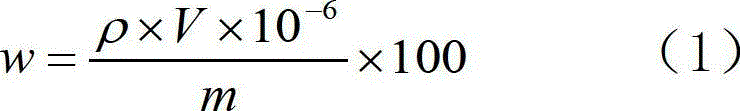

[0044] Determination of zirconium content in tantalum-cobalt-based superalloy K6509 is characterized in that: the steps of the determination method are:

[0045] (1) The reagents used in the determination process of this method are:

[0046] 1.1 Hydrochloric acid, ρ1.19g / mL, superior grade or MOS grade;

[0047] 1.2 Nitric acid, ρ1.42g / mL;, excellent grade pure or MOS grade

[0048] 1.3 Hydrofluoric acid, ρ1.15g / mL, superior grade;

[0049] 1.4 Sulfuric acid, ρ1.84g / mL, superior grade;

[0050] 1.5 Zirconium standard solution, 0.10mg / mL, the preparation method is to weigh 0.1351g of zirconium dioxide, put it in a platinum crucible, add 10mL of hydrofluoric acid in the above step 1.3 and 6mL of nitric acid in the above step 1.2, and dissolve it by heating at low temperature , add 10mL of sulfuric acid in the above step 1.4, heat and evaporate to sulfuric acid fumes, add water and mix the solution carefully, after cooling, transfer the solution into a 1000mL volumetric flask,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com