Method for measuring potassium and sodium in high titanium blast furnace slag

A blast furnace slag, high titanium technology, applied in the field of chemical analysis, can solve the problems of large influence of the element to be measured, inaccurate measurement results, spectral interference, etc., to achieve the effect of fast sample dissolution, not easy to contaminate and decompose, and accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

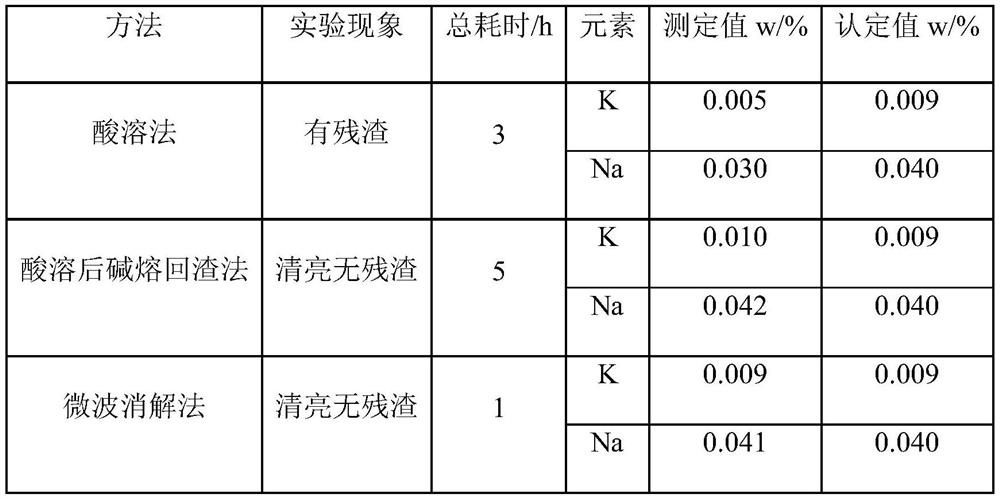

[0059] a. Microwave digestion: Weigh 0.5000g high-titanium blast furnace slag standard sample, add 8mL hydrochloric acid, 5mL hydrofluoric acid, 5mL water, pre-digest until no yellow smoke is emitted, perform microwave digestion in the digestion apparatus, and set the pressure of the digestion apparatus The rate of rise is 31.5kPa / s, the upper limit of pressure is 3990kPa, and the upper limit of temperature is 240°C. First, the temperature is raised at 300W for 10 minutes and kept for 5 minutes, then the temperature is raised at 600W for 10 minutes and kept for 10 minutes. In the bottle, dilute to volume with water and mix to obtain the test solution;

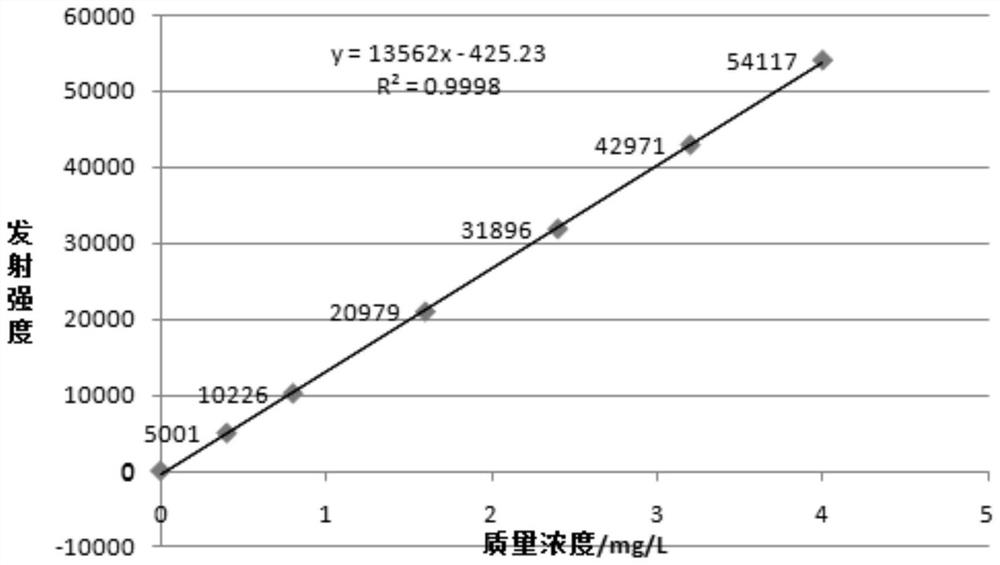

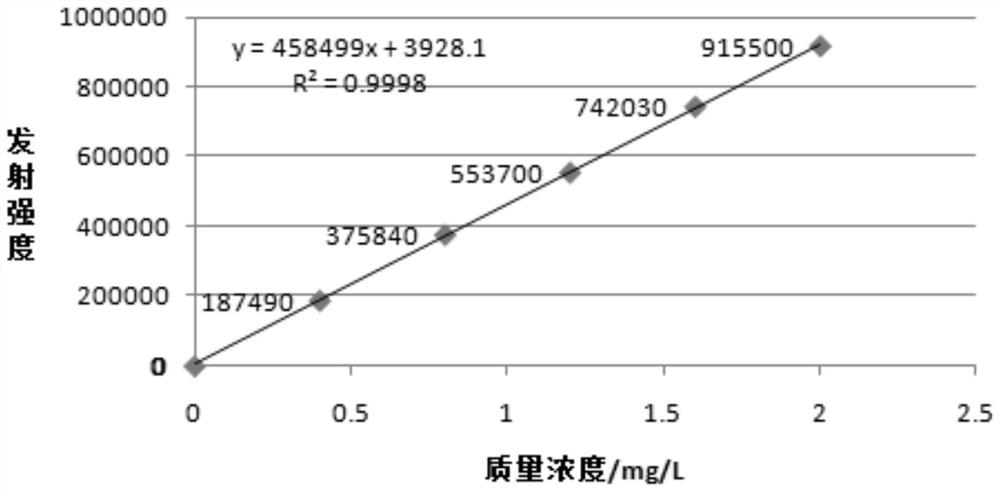

[0060] b. Preparation of blank solution and standard solution: Weigh 30g of pure iron, add 500mL of hydrochloric acid, heat at 50-80°C for 2-3 hours to dissolve slowly, add dropwise 20-30mL of nitric acid for oxidation, cool down, dilute to 1000mL with water, mix Mix evenly to obtain an iron matrix solution; take 10 mL of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com