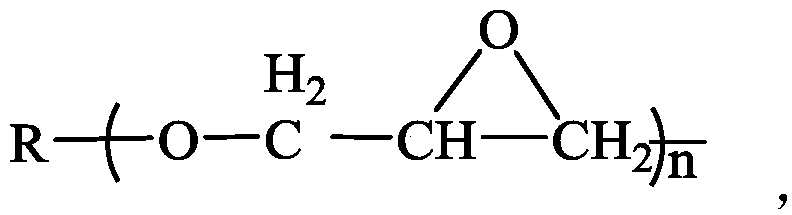

Polyhydroxy vinyl ester resin, preparation method thereof and thickening method

A polyhydroxy vinyl ester and resin technology, applied in the field of resin composite materials, can solve the problems of difficult control of the reaction, influence on the degree of curing, and decrease in hardness, so as to increase the length and viscosity of the system, reduce the curing shrinkage rate, and consume less energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

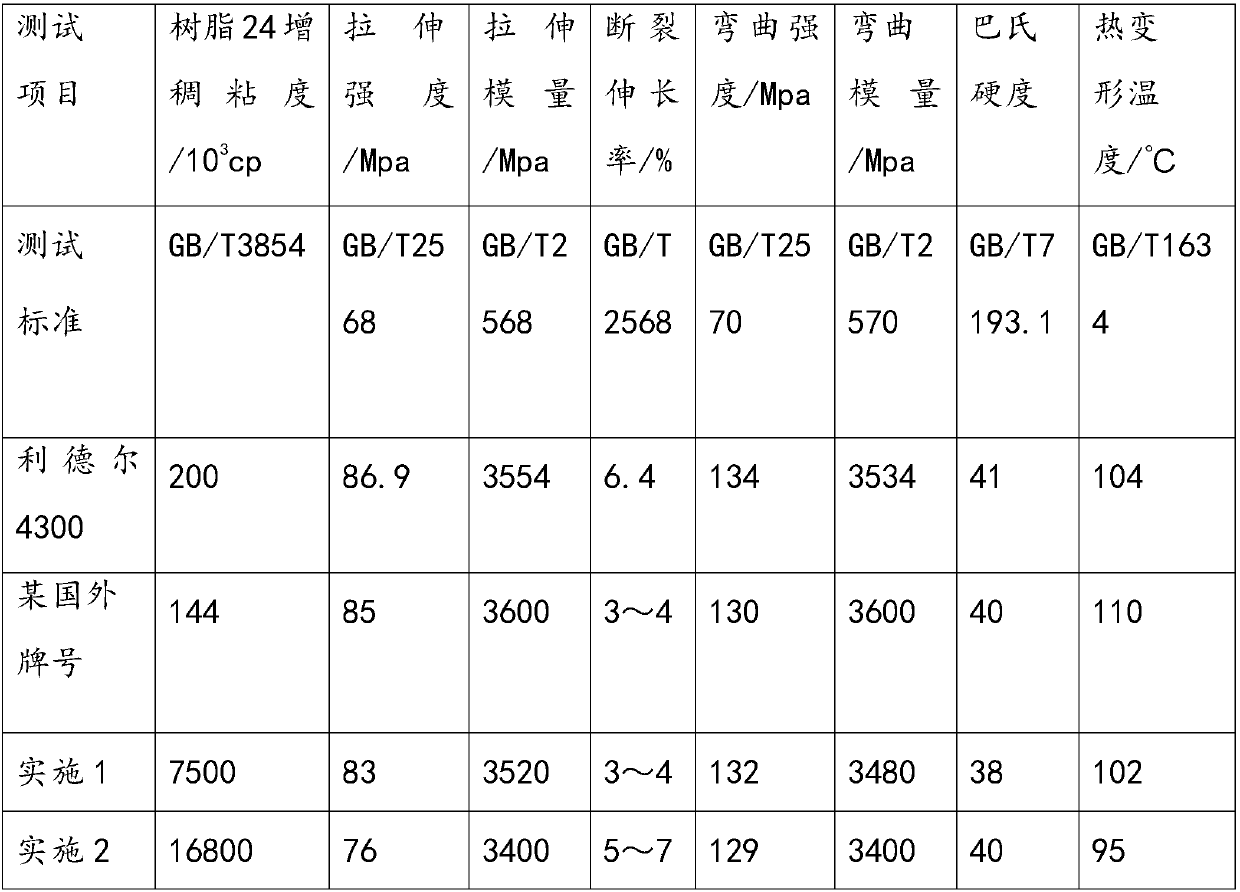

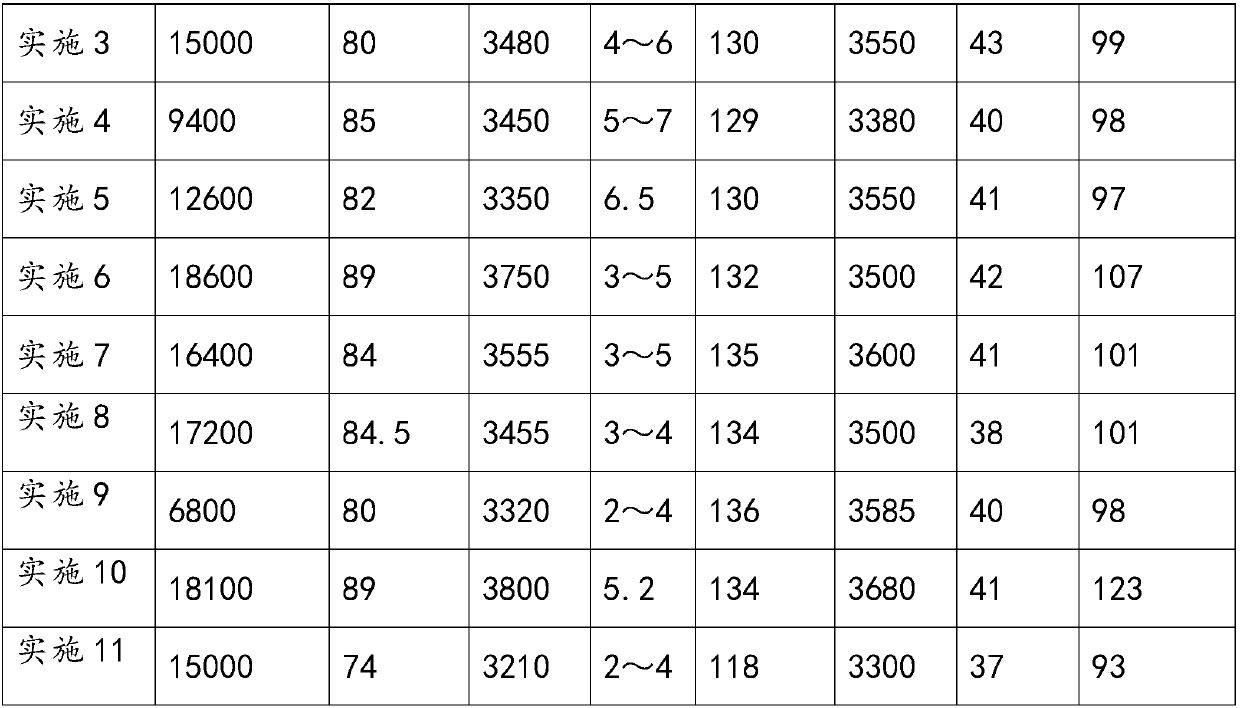

Embodiment 1

[0032] A polyhydroxy vinyl ester resin, comprising the following components in parts by weight: 30 parts of glycerol triglycidyl ether, 30 parts of bisphenol A type epoxy resin, 30 parts of methacrylic acid, 30 parts of styrene, benzyl 0.01 part of diethylamine and 0.1 part of hydroquinone.

[0033] A preparation method of polyhydroxy vinyl ester resin, comprising the steps of:

[0034] S1. at room temperature, under the protection of nitrogen, the glycerol triglycidyl ether, bisphenol A type epoxy resin, hydroquinone and benzyldiethylamine of the above formula amount are placed in a closed container for continuous stirring, and Add the above formula amount of methacrylic acid in batches within 120 minutes, then raise the temperature to 65°C at a rate of 3°C / min, control the heating rate so that the system is heated to 90°C within 120 minutes, and keep warm for 210 minutes;

[0035] S2. Add the above-mentioned amount of styrene to the product obtained in S1, continue stirring...

Embodiment 2

[0040] A polyhydroxy vinyl ester resin, comprising the following components in parts by weight: 20 parts of glycerol triglycidyl ether, 35 parts of bisphenol A type epoxy resin, 30 parts of methacrylic acid, 40 parts of styrene, benzyl 0.05 part of diethylamine and 0.1 part of hydroquinone.

[0041] A preparation method of polyhydroxy vinyl ester resin, comprising the steps of:

[0042] S1. at room temperature, under the protection of nitrogen, the glycerol triglycidyl ether, bisphenol A type epoxy resin, hydroquinone and benzyldiethylamine of the above formula amount are placed in a closed container for continuous stirring, and Add the methacrylic acid in the amount of the above formula in batches within 90 minutes, then raise the temperature to 70°C at a rate of 5°C / min, control the heating rate so that the system is heated to 90°C within 105 minutes, and keep warm for 180 minutes;

[0043] S2. Add the above-mentioned amount of styrene to the product obtained in S1, continu...

Embodiment 3

[0048] A polyhydroxy vinyl ester resin, comprising the following components in parts by weight: 10 parts of glycerol triglycidyl ether, 50 parts of bisphenol A type epoxy resin, 30 parts of methacrylic acid, 30 parts of styrene, benzyl 0.05 part of diethylamine and 0.1 part of hydroquinone.

[0049] A preparation method of polyhydroxy vinyl ester resin, comprising the steps of:

[0050] S1. at room temperature, under the protection of nitrogen, the glycerol triglycidyl ether, bisphenol A type epoxy resin, hydroquinone and benzyldiethylamine of the above formula amount are placed in a closed container for continuous stirring, and Add the methacrylic acid in the amount of the above formula in batches within 60 minutes, then raise the temperature to 75°C at a rate of 4°C / min, control the heating rate so that the system is heated to 95°C within 90 minutes, and keep warm for 120 minutes;

[0051] S2. Add the above-mentioned amount of styrene to the product obtained in S1, continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com