A method for repairing silver grid wire electrodes of crystalline silicon solar cells

A technology of crystalline silicon solar cells and wire electrodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult control of the growth rate of the electroplated silver layer, poor surface quality of grid lines, and easy formation of flaky crystals, etc., to avoid Further recession, excellent surface quality, rapid thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

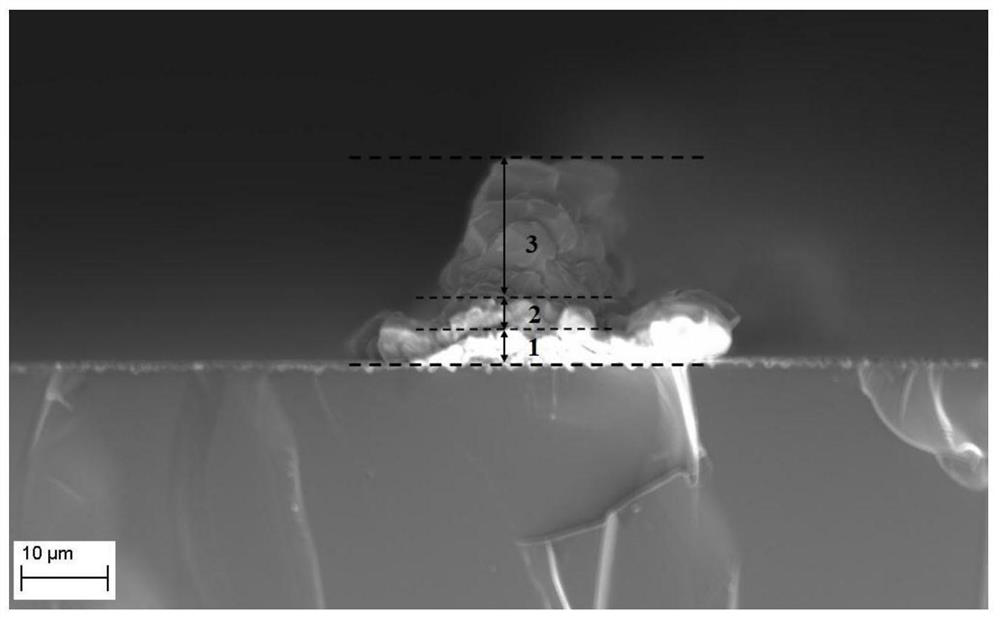

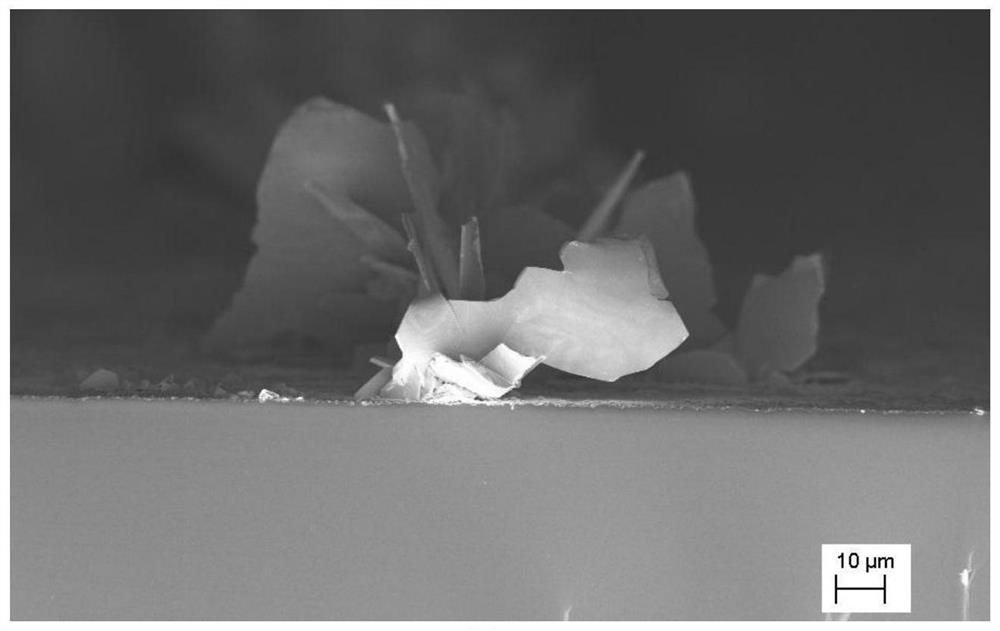

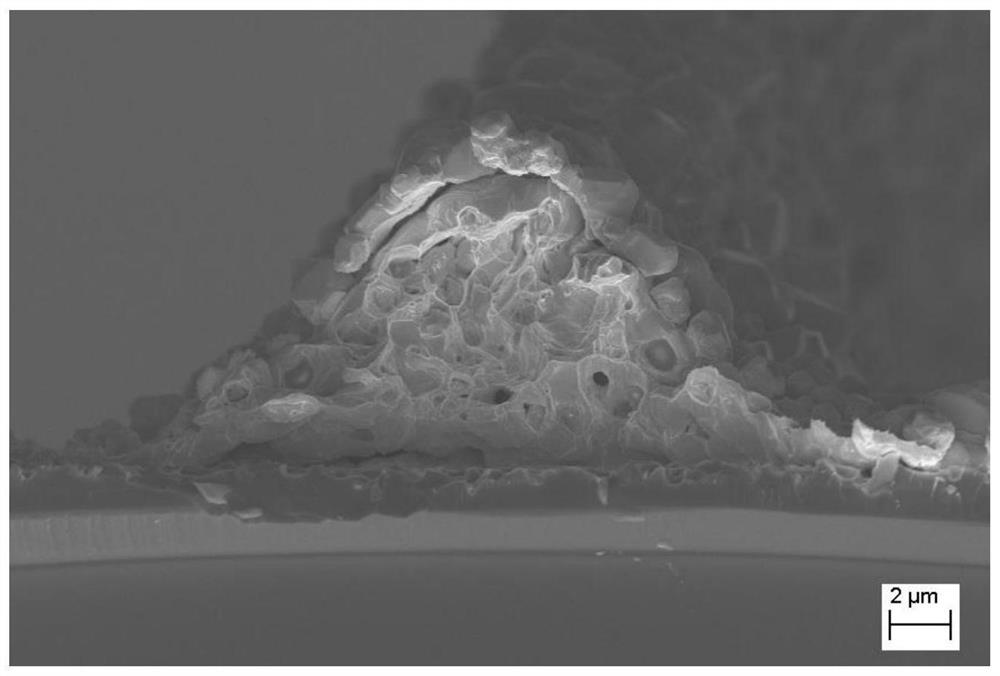

Image

Examples

Embodiment 1

[0057] According to the method disclosed in the national standard GB 11010-1989, the conversion efficiency of waste crystalline silicon solar cells is tested. The test conditions are: the solar radiation spectrum is AM1.5, and the sunlight irradiance is 1000W / m 2 , the test temperature is 25°C, the result is 8.22%;

[0058] Rinse the waste crystalline silicon solar cell tested above with deionized water for 30 minutes, dry it, and then place the packaging plate opposite to the positive electrode surface of the waste crystalline silicon solar cell. The shape of the packaging plate is suitable for the surface of the positive electrode, and the material is glass. Seal the gap with adhesive tape to obtain a positive-sealed waste crystalline silicon solar cell;

[0059] Add 250 mL of silver nitrate aqueous solution with a concentration of 0.4 mol / L dropwise to 500 mL of an aqueous solution of ammonium sulfate with a concentration of 2 mol / L, keep the aqueous solution of ammonium su...

Embodiment 2

[0067] According to the method of Example 1, the conversion efficiency of the waste crystalline silicon solar cell used in this example was tested, and the result was 9.13%;

[0068] Rinse the waste crystalline silicon solar cell tested above with deionized water for 30 minutes, dry it, and then place the packaging plate opposite to the positive electrode surface of the waste crystalline silicon solar cell. The shape of the packaging plate is suitable for the surface of the positive electrode, and the material is glass. Seal the gap with adhesive tape to obtain a positive-sealed waste crystalline silicon solar cell;

[0069] 250mL concentration of 2mol / L silver nitrate aqueous solution is added dropwise to 500mL concentration of 1mol / L ammonium sulfate aqueous solution, the dropwise addition process maintains the ammonium sulfate aqueous solution stirring state, then drips 250mL concentration of 0.8mol / L glucose aqueous solution, Obtain primary electroless silver plating liqui...

Embodiment 3

[0076] According to the method of Example 1, the conversion efficiency of the waste crystalline silicon solar cell used in this example was tested, and the result was 7.35%;

[0077] Rinse the waste crystalline silicon solar cell tested above with deionized water for 30 minutes, dry it, and then place the packaging plate opposite to the positive electrode surface of the waste crystalline silicon solar cell. The shape of the packaging plate is suitable for the surface of the positive electrode, and the material is glass. Seal the gap with adhesive tape to obtain a positive-sealed waste crystalline silicon solar cell;

[0078] Add 250mL of silver nitrate aqueous solution with a concentration of 0.8mol / L dropwise to 500mL of ammonium sulfate aqueous solution with a concentration of 2mol / L. During the dropping process, keep the ammonium sulfate aqueous solution in a stirring state, and then add 250mL of glucose aqueous solution with a concentration of 0.4mol / L dropwise. , obtain p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com