A composite foaming agent for cast-in-place foam concrete

A composite foaming agent and foam concrete technology, which is applied in the field of anionic-nonionic surfactant composite foaming agent for cast-in-place foam concrete, can solve the problems of expensive imported products, increase water carrying capacity and reduce foam loss , excellent foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

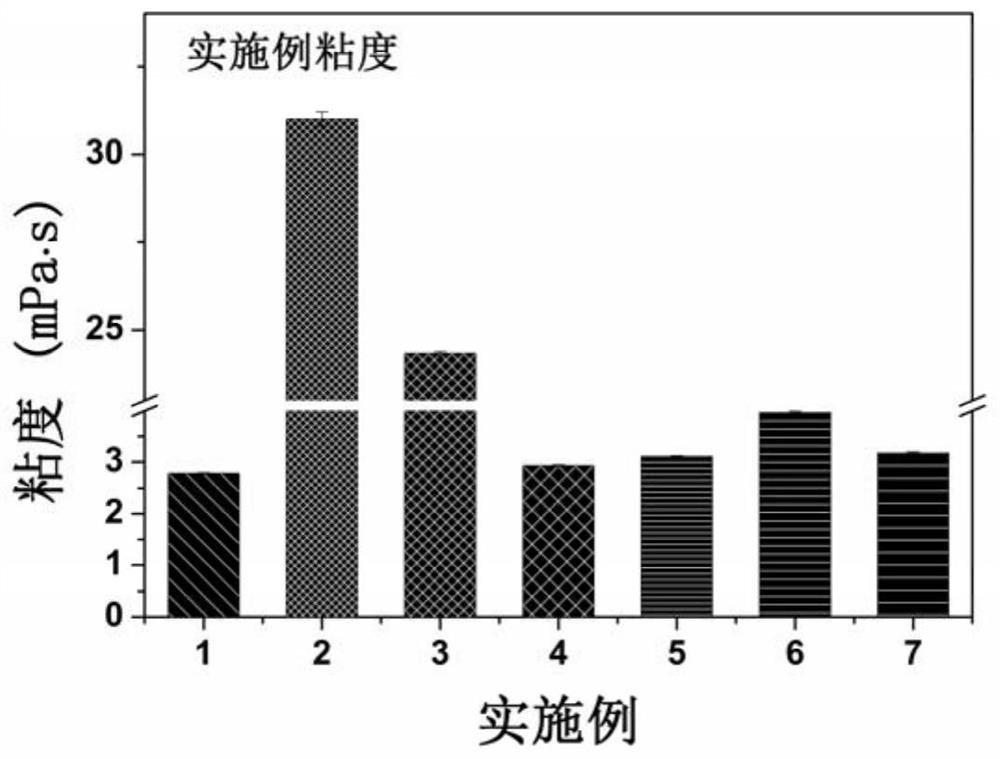

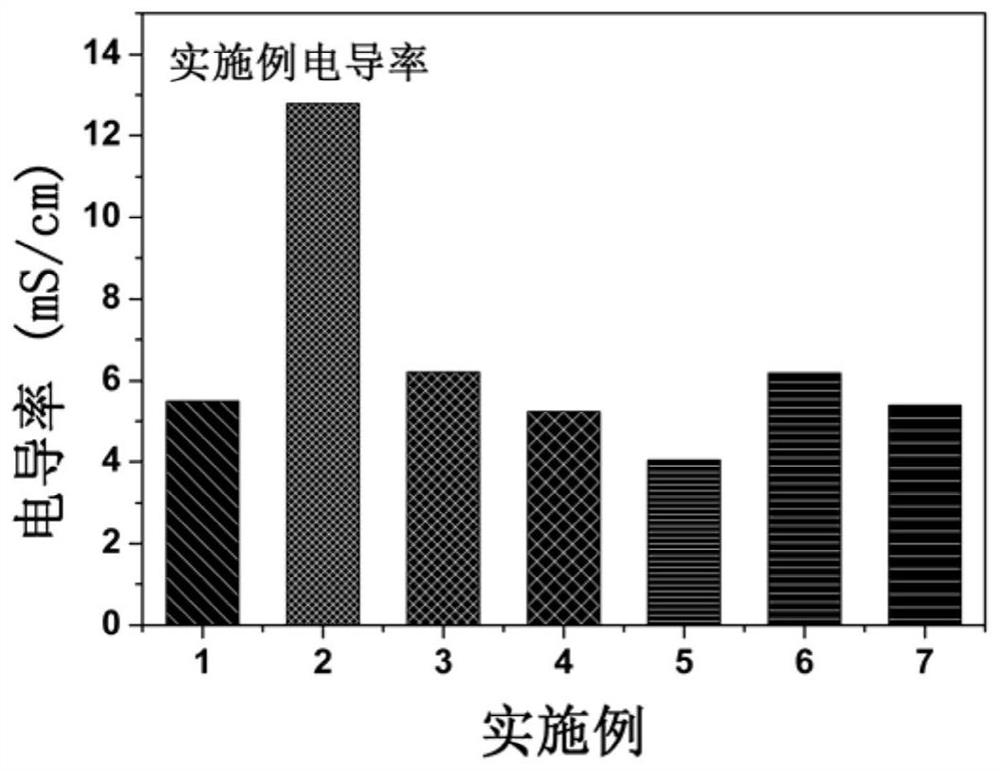

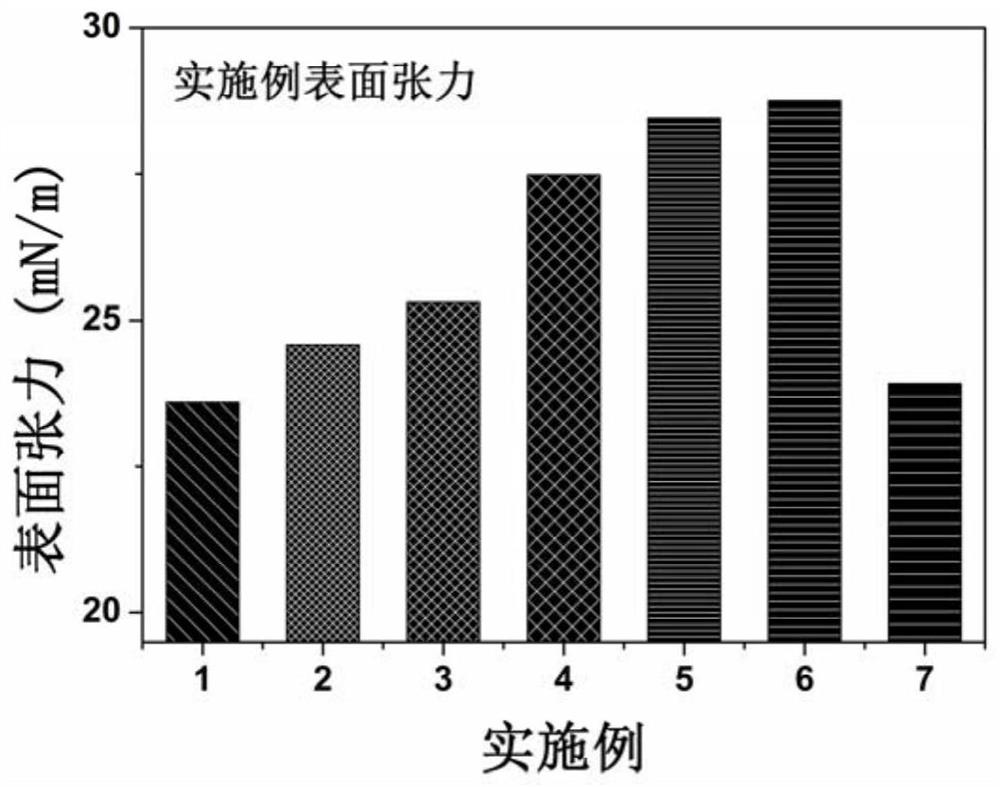

Examples

Embodiment 1

[0021] Mix 12g of sodium fatty alcohol polyoxyethylene ether sulfate, 6g of lauryl alkyl glucoside, 2g of modified silicone resin polyether emulsion and 180g of water to obtain a composite blowing agent.

Embodiment 2

[0023] Mix 12g of sodium fatty alcohol polyoxyethylene ether sulfate, 6g of lauryl alkyl glucoside, 2g of modified silicone polyether emulsion, 0.5g of polyacrylamide and 200g of water to obtain a composite blowing agent.

Embodiment 3

[0025] Mix 12g sodium fatty alcohol polyoxyethylene ether sulfate, 6g lauryl alkyl glucoside, 2g modified silicone resin polyether emulsion, 0.5g hydroxypropyl methylcellulose and 200g water to obtain a composite blowing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com