Research, development and preparation method of trunk injection pesticide adjuvant

A technology of pesticide adjuvants and cosolvents, which is applied in the fields of botanical equipment and methods, biocides, biocides, etc. The effect of reducing the decomposition release rate and increasing the viscosity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

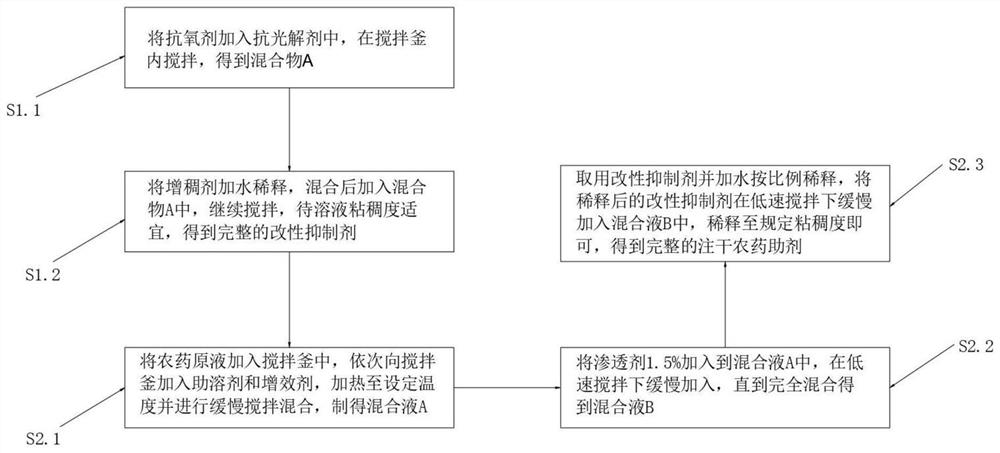

Method used

Image

Examples

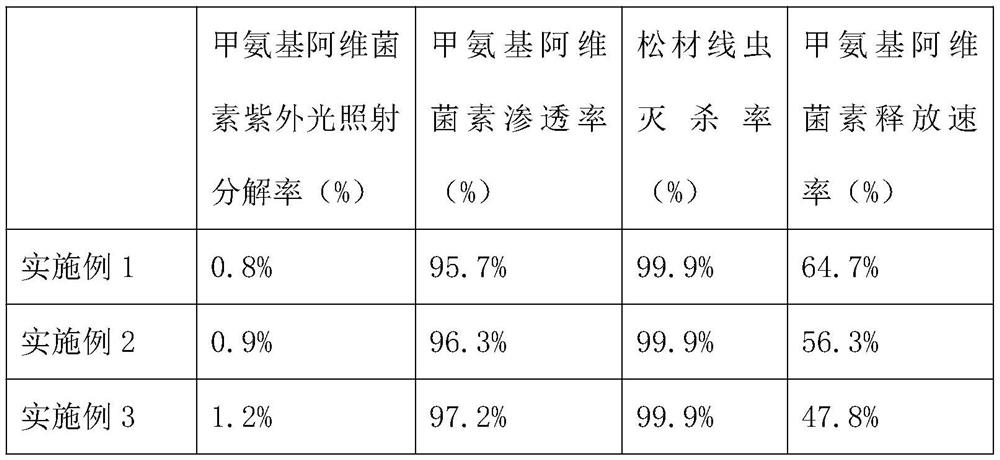

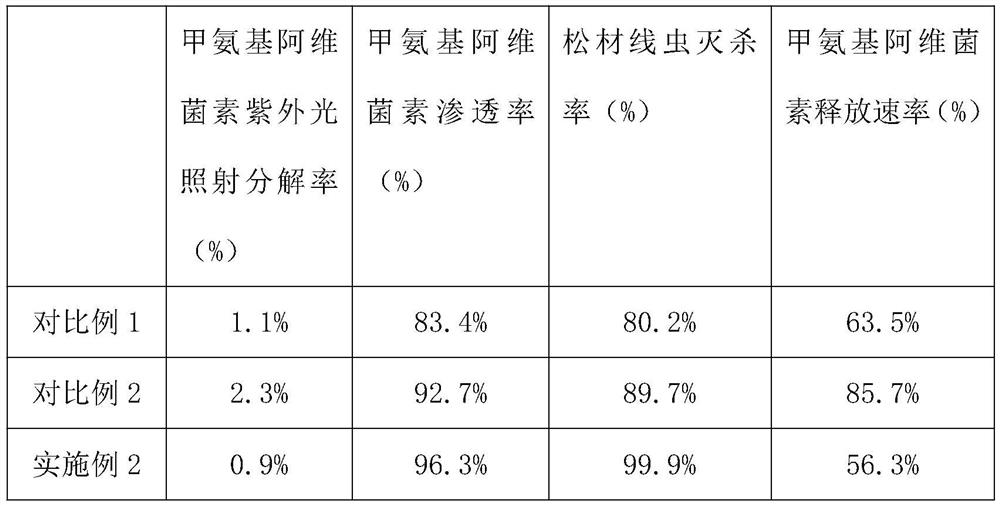

Embodiment 1

[0029] Embodiment 1 A research and development and preparation method of dry injection pesticide adjuvant, comprising:

[0030] S1.1. Add 30% of antioxidant to 60% of anti-photolysis agent, and stir in the stirring tank for 15 minutes to obtain mixture A;

[0031] S1.2. Dilute 0.5% thickener with deionized water, mix and add to mixture A, and continue to stir for 10 minutes to obtain a complete modified inhibitor.

[0032] S2.1. Add the original drug into the stirred tank, add 48.5% of co-solvent and 4% of synergist to the stirred tank in turn, heat to 45°C and slowly stir and mix to prepare the mixed solution A;

[0033] S2.2. Add 1.5% penetrant to the mixed solution A, and slowly add it under low-speed stirring until it is completely mixed to obtain the mixed solution B;

[0034] S2.3. Take 6% of the modified inhibitor and dilute it with water in proportion, slowly add the diluted modified inhibitor into the mixed solution B under low-speed stirring, and dilute the viscosit...

Embodiment 2

[0035] Embodiment 2 A research and development and preparation method of dry injection pesticide adjuvant, comprising:

[0036] S1.1. Add 35% of antioxidant to 55% of anti-photolysis agent, and stir in the stirring tank for 20 minutes to obtain mixture A;

[0037] S1.2. Dilute 1% thickener with deionized water, mix and add to mixture A, and continue to stir for 15 minutes to obtain a complete modified inhibitor.

[0038] S2.1. Add the original drug into the stirred tank, add 29% of co-solvent and 6% of synergist to the stirred tank in turn, heat to 45°C and slowly stir and mix to prepare the mixed solution A;

[0039] S2.2. Add 2% penetrant to the mixed solution A, and slowly add it under low-speed stirring until it is completely mixed to obtain the mixed solution B;

[0040]S2.3. Take 8% of the modified inhibitor and dilute it with water in proportion. Slowly add the diluted modified inhibitor into the mixed solution B under low-speed stirring, and dilute the viscosity to 5....

Embodiment 3

[0041] Embodiment 3 A research and development and preparation method of dry injection pesticide adjuvant, comprising:

[0042] S1.1. Add 40% of antioxidant to 50% of anti-photolysis agent, and stir in the stirring tank for 130 minutes to obtain mixture A;

[0043] S1.2. Dilute 1.2% thickener with deionized water, mix and add to mixture A, and continue to stir for 20 minutes to obtain a complete modified inhibitor.

[0044] S2.1. Add the original drug into the stirring tank, add 19% of co-solvent and 8% of synergist to the stirring tank in turn, heat to 45°C and slowly stir and mix to prepare the mixed solution A;

[0045] S2.2. Add 3% penetrant to the mixed solution A, and slowly add it under low-speed stirring until it is completely mixed to obtain the mixed solution B;

[0046] S2.3. Take 10% of the modified inhibitor and dilute it with water in proportion. Slowly add the diluted modified inhibitor into the mixed solution B under low-speed stirring, and dilute the viscosit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com