Slow-release type organic granular fertilizer and preparation method thereof

An organic granule, slow-release technology, applied in the preparation of organic fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve the problems of fertilizer efficiency not being maintained for several months, fertilizer waste, fertilizer loss, etc., to facilitate absorption and utilization, improve Economic benefit, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

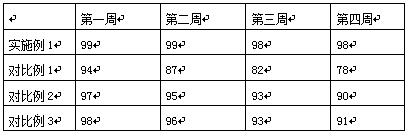

Examples

Embodiment 1

[0022] A slow-release organic granular fertilizer, the components by weight are as follows: 30 parts of straw, 10 parts of vermicompost, 5 parts of manure, 5 parts of vermiculite, 10 parts of plant ash, 5 parts of kaolin, 4 parts of montmorillonite, trace elements 5 parts of solution, 15 parts of slow release additive.

[0023] Preferably, the straw is prepared by mixing corn straw, wheat straw and soybean straw according to the weight ratio of 1:1.5:2.

[0024] Preferably, the manure is prepared by mixing cow manure, sheep manure, pig manure and horse manure in a weight ratio of 1:1:2:2.

[0025] Preferably, the trace element solution is prepared by mixing potassium phosphate, magnesium sulfate, manganese sulfate, sodium phosphate, and boric acid in a weight ratio of 1:1:1:1.5:1.5.

[0026] As preferably, the preparation method of wherein said slow-release additive is as follows:

[0027] 1) Take 5 parts of ethyl acrylate and 7 parts of methyl methacrylate, add 2 parts of z...

Embodiment 2

[0036] A slow-release organic granular fertilizer, the components by weight are as follows: 40 parts of straw, 15 parts of vermicompost, 10 parts of manure, 10 parts of vermiculite, 15 parts of plant ash, 6 parts of kaolin, 5 parts of montmorillonite, trace elements 7 parts of solution, 20 parts of slow release additive.

[0037] Preferably, the straw is prepared by mixing corn straw, wheat straw and soybean straw according to the weight ratio of 1:1.5:2.

[0038] Preferably, the manure is prepared by mixing cow manure, sheep manure, pig manure and horse manure in a weight ratio of 1:1:2:2.

[0039] Preferably, the trace element solution is prepared by mixing potassium phosphate, magnesium sulfate, manganese sulfate, sodium phosphate, and boric acid in a weight ratio of 1:1:1:1.5:1.5.

[0040] As preferably, the preparation method of wherein said slow-release additive is as follows:

[0041] 1) Take 7 parts of ethyl acrylate and 10 parts of methyl methacrylate, add 2 parts o...

Embodiment 3

[0050] A slow-release organic granular fertilizer, the components by weight are as follows: 50 parts of straw, 20 parts of vermicompost, 15 parts of manure, 15 parts of vermiculite, 20 parts of plant ash, 8 parts of kaolin, 7 parts of montmorillonite, trace elements 8 parts of solution, 30 parts of slow release additive.

[0051] Preferably, the straw is prepared by mixing corn straw, wheat straw and soybean straw according to the weight ratio of 1:1.5:2.

[0052] Preferably, the manure is prepared by mixing cow manure, sheep manure, pig manure and horse manure in a weight ratio of 1:1:2:2.

[0053] Preferably, the trace element solution is prepared by mixing potassium phosphate, magnesium sulfate, manganese sulfate, sodium phosphate, and boric acid in a weight ratio of 1:1:1:1.5:1.5.

[0054] As preferably, the preparation method of wherein said slow-release additive is as follows:

[0055] 1) Take 10 parts of ethyl acrylate and 13 parts of methyl methacrylate, add 3 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com