High-light-absorptivity solar heat-absorbing paint

A technology of solar heat absorption and light absorption rate, applied in the field of solar coatings, can solve the problems of limitation, high cost, instability, etc., and achieve the effects of high absorption rate, improved absorption power, and high degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

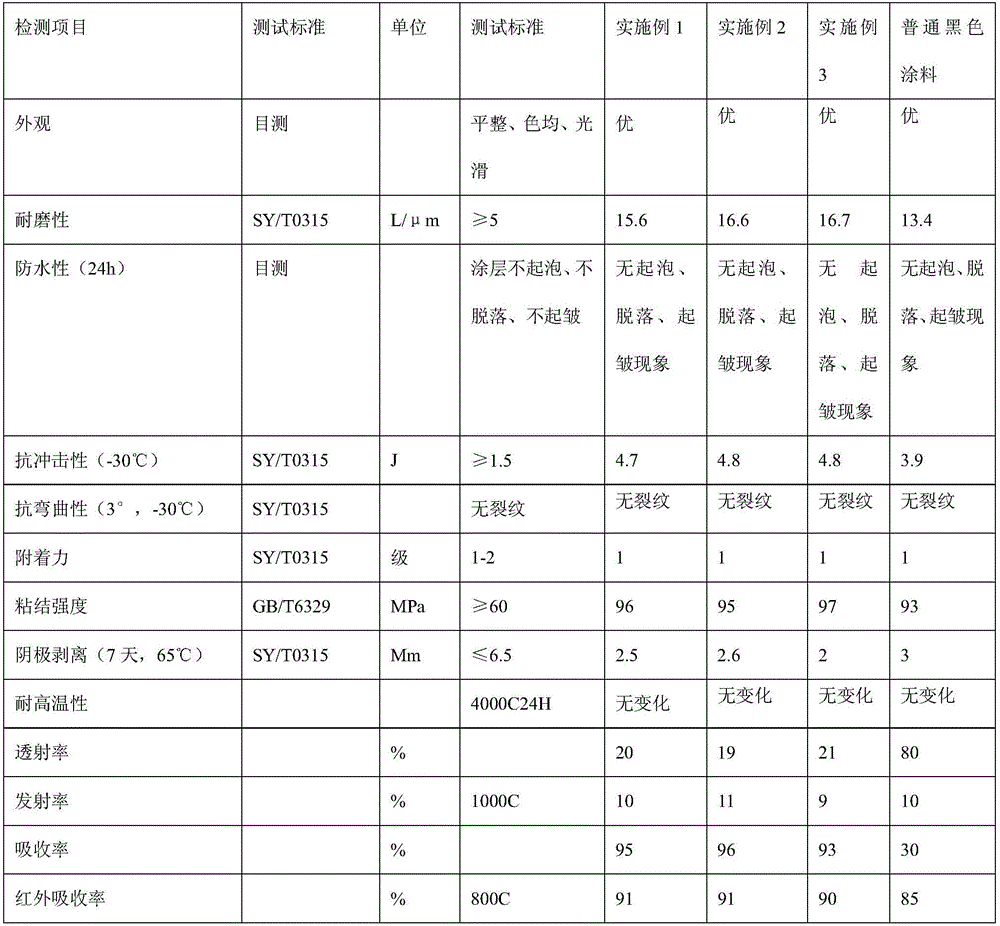

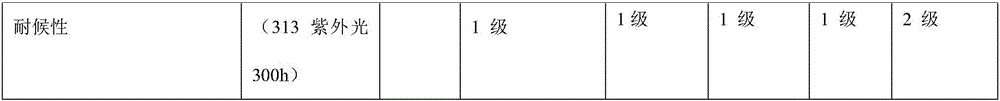

Examples

Embodiment 1

[0024] A kind of solar paint with high light absorption rate, its raw material is:

[0025] Resin: modified polyurethane resin 55Kg;

[0026] Light absorbing agent: use channel black 35Kg, iron oxide black 30Kg, red powder 8Kg, modified phthalocyanine blue 20Kg, talcum powder 3Kg and aluminum powder 4Kg;

[0027] Solvent: a mixture of acetone and toluene (volume ratio 9:1);

[0028] Auxiliaries are defoamers, plasticizers and drier, wherein,

[0029] Defoamer: polyoxyethylene polyoxypropylene pentaerythritol ether 1Kg;

[0030] Plasticizer: diethyl phthalate 1Kg;

[0031] Drying agent: manganese dioxide naphthenic acid soap 1Kg, cobalt naphthenic acid soap 1Kg;

[0032] The steps of preparing a solar heat absorbing coating with high light absorption rate according to the above-mentioned raw materials are as follows:

[0033] (1) First, take out 15Kg of phthalocyanine blue in parts by weight, add 40mL of concentrated sulfuric acid, stir for 5min, heat to 80°C and reflux, s...

Embodiment 2

[0037] A kind of solar paint with high light absorption rate, its raw material is:

[0038] Resin: modified polyurethane resin 65Kg;

[0039] Light absorbing agent: use channel black 37Kg, iron oxide black 32Kg, red powder 10Kg, modified phthalocyanine blue 22Kg, talcum powder 4Kg and aluminum powder 6Kg;

[0040] Solvent: a mixture of tetrahydrofuran and toluene (volume ratio 9:1);

[0041] Auxiliaries are defoamers, plasticizers and drier, wherein,

[0042] Defoamer: polyoxyethylene polyoxypropanolamine ether 1Kg;

[0043] Plasticizer: dibutyl phthalate 1.5Kg;

[0044] Drying agent: lead naphthenic acid soap 1Kg, cobalt naphthenic acid soap 1Kg;

[0045] The steps of preparing a solar heat absorbing coating with high light absorption rate according to the above-mentioned raw materials are as follows:

[0046] (1) First take out 18Kg of phthalocyanine blue according to the ratio of parts by weight, add 45mL of concentrated sulfuric acid, stir for 8min, heat to reflux at 90...

Embodiment 3

[0050] A kind of solar paint with high light absorption rate, its raw material is:

[0051] Resin: modified polyurethane resin 75Kg;

[0052] Light absorbing agent: use channel black 40Kg, iron oxide black 35Kg, red powder 12Kg, modified phthalocyanine blue 25Kg, talcum powder 5Kg and aluminum powder 8Kg;

[0053] Solvent: ethyl acetate and phosphoric acid mixture (volume ratio 9:1);

[0054] Auxiliaries are defoamers, plasticizers and drier, wherein,

[0055] Defoamer: polyoxypropylene glyceryl ether 3Kg;

[0056] Plasticizer: dibutyl phthalate 2Kg;

[0057] Drying agent: lead naphthenic acid soap 1Kg, cobalt naphthenic acid soap 1Kg, manganese dioxide naphthenic acid soap 1Kg;

[0058] The steps of preparing a solar heat absorbing coating with high light absorption rate according to the above-mentioned raw materials are as follows:

[0059] (1) First take out 20Kg of phthalocyanine blue according to the ratio of parts by weight, add 50mL of concentrated sulfuric acid, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com