High-wear-resistance anti-slip EVA composite foam material and preparation method thereof

A composite foam and composite material technology, which is applied in the field of high wear-resistant anti-slip EVA composite foam material and its preparation, can solve the problems of polluting the environment, steel slag cannot be processed in time, and steel slag occupies land, etc., so as to improve the surface structure and enhance wear resistance The effect of high resistance and load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A high wear-resistant anti-slip EVA composite foam material, the composition of the raw material formula is calculated by weight: 70 parts of ethylene-vinyl acetate copolymer, 10 parts of maleic anhydride grafted EVA, 10 parts of ethylene-octene copolymer, terpene 5 parts of resin, 2.5 parts of wear-resistant anti-slip agent, 2 parts of naphthenic oil, 1 part of polyisobutylene, 2 parts of foaming agent AC, 1 part of accelerator tetramethylthiuram disulfide, 0.5 part of stearic acid, hard 0.5 parts of zinc fatty acid, 5 parts of zinc oxide, 1.5 parts of dicumyl peroxide, and 1 part of antioxidant 2,6-di-tert-butyl-4-methylphenol.

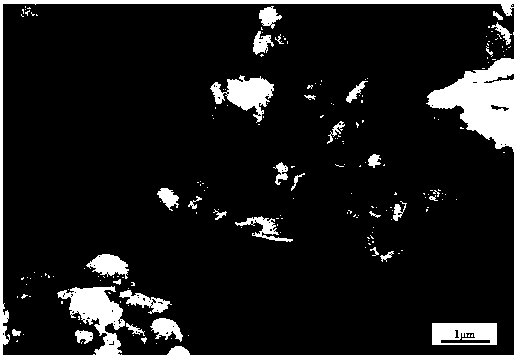

[0027] 1) Take a certain amount of stearic acid in a three-necked flask, add 150ml of absolute ethanol to ultrasonically disperse for 60min, take 10g of steel slag powder and add it to the flask, stir and react at 50°C for 12h to obtain modified steel slag;

[0028] 2) Dissolve 1g of expanded graphite in 23ml of concentrated sulfuric acid, ke...

Embodiment 2

[0035]A high wear-resistant anti-slip EVA composite foam material, the composition of the raw material formula is calculated by weight: 70 parts of ethylene-vinyl acetate copolymer, 10 parts of maleic anhydride grafted EVA, 10 parts of ethylene-octene copolymer, terpene 5 parts of resin, 5 parts of wear-resistant anti-slip agent, 2 parts of naphthenic oil, 1 part of polyisobutylene, 2 parts of foaming agent AC, 1 part of accelerator tetramethylthiuram disulfide, 0.5 part of stearic acid, hard 0.5 parts of zinc fatty acid, 5 parts of zinc oxide, 1.5 parts of dicumyl peroxide, and 1 part of antioxidant 2,6-di-tert-butyl-4-methylphenol.

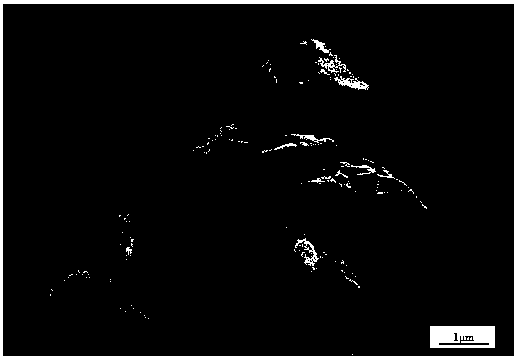

[0036] 1) Take a certain amount of stearic acid in a three-necked flask, add 150ml of absolute ethanol to ultrasonically disperse for 60min, take 10g of steel slag powder and add it to the flask, stir and react at 50°C for 12h to obtain modified steel slag;

[0037] 2) Dissolve 1g of expanded graphite in 23ml of concentrated sulfuric acid, keep ...

Embodiment 3

[0044] A high wear-resistant anti-slip EVA composite foam material, the composition of the raw material formula is calculated by weight: 70 parts of ethylene-vinyl acetate copolymer, 10 parts of maleic anhydride grafted EVA, 10 parts of ethylene-octene copolymer, terpene 5 parts of resin, 7.5 parts of anti-slip agent, 2 parts of naphthenic oil, 1 part of polyisobutylene, 2 parts of foaming agent AC, 1 part of accelerator tetramethylthiuram disulfide, 0.5 part of stearic acid, hard 0.5 parts of zinc fatty acid, 5 parts of zinc oxide, 1.5 parts of dicumyl peroxide, and 1 part of antioxidant 2,6-di-tert-butyl-4-methylphenol.

[0045] 1) Take a certain amount of stearic acid in a three-necked flask, add 150ml of absolute ethanol to ultrasonically disperse for 60min, take 10g of steel slag powder and add it to the flask, stir and react at 50°C for 12h to obtain modified steel slag;

[0046] 2) Dissolve 1g of expanded graphite in 23ml of concentrated sulfuric acid, keep uniform magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com