River sludge composite curing material with high organic matter content and application thereof

A technology for river silt and solidification materials, which is applied in the field of composite solidification materials to solidify high-organic river silt into building materials and composite solidification materials. The effect of increasing curing strength and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

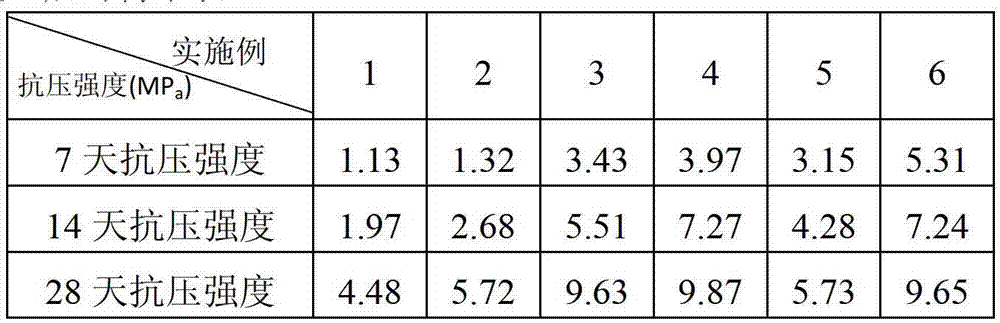

Embodiment 1

[0022] The mass percent of each component in this example is: high organic matter river silt (52.36%), 32.5 grade Portland cement (18.32%), fly ash (18.32%), quicklime (4.97%), yellow sand (6.03%) ).

Embodiment 2

[0024] The mass percent of each component in this example is: high organic matter sludge (52.25%), 32.5 grade Portland cement (18.29%), fly ash (18.29%), quicklime (4.96%), yellow sand (6.00%) , enhancer (0.21%).

Embodiment 3

[0026] The mass percent of each component in this example is: high organic matter sludge (49.93%), 32.5 grade Portland cement, fly ash (17.47%), quicklime (4.74%), yellow sand (5.74%), activator ( 4.65%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com