Oily sludge drying agent, and preparation and application methods thereof

An application method and drying agent technology, applied in chemical instruments and methods, sludge treatment, fixed/solidified sludge treatment, etc., can solve the problems of high processing cost, low drying efficiency, high viscosity, etc., and achieve the preparation cost. Low cost, easy availability of raw materials, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the above-mentioned oily sludge desiccant is as follows: fly ash, limestone, gypsum and additives are added in a certain proportion to the stirring homogeneous kettle, fully mixed and homogenized, and the oily sludge is obtained after uniform mixing. agent.

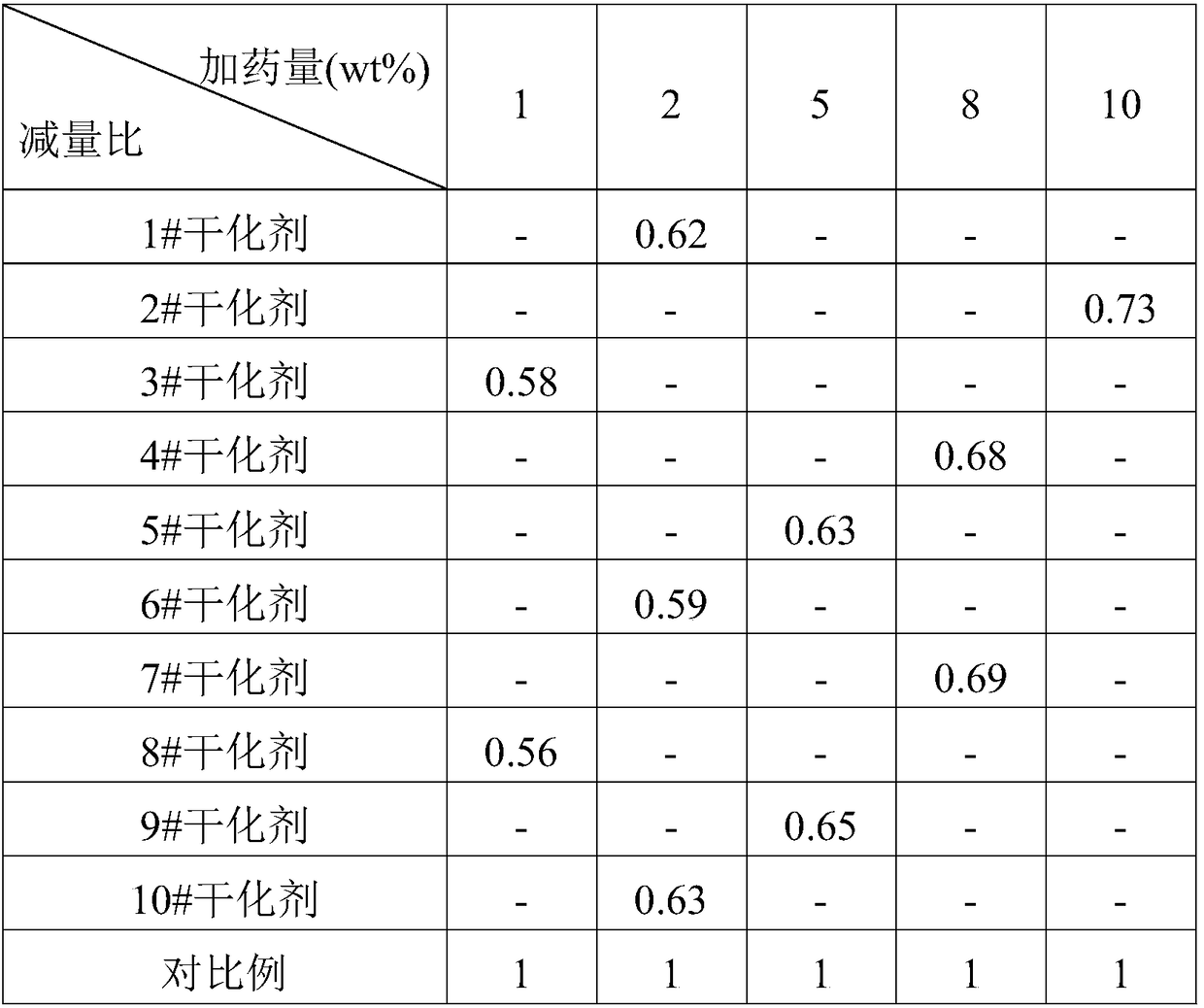

[0037] The application method of the oily sludge drying agent described in the present invention: use a dry powder dosing device to add the oily sludge drying agent, then use a kneader to fully mix the oily sludge drying agent and oily sludge, and then send into the oily sludge drying machine; the mass percentage of the added oily sludge drying agent in the undried oily sludge is 1-10%, and the preferred range is 2-5%.

preparation Embodiment 1

[0039] The drying agent and preparation method thereof for oily sludge drying described in the present invention are as follows:

[0040] (1) fly ash, its mass percentage composition is 70wt%;

[0041] (2) limestone, its mass percentage composition is 9.5wt%;

[0042] (3) Gypsum, its mass percentage composition is 20wt%;

[0043] (4) auxiliary agent, the mass percentage of sodium lignosulfonate is 0.5wt%.

[0044] Add it into the stirring homogeneous kettle according to the above ratio, and fully mix and homogenize. The evenly mixed material is the oily sludge desiccant, called 1# desiccant.

preparation Embodiment 2

[0046] The drying agent and preparation method thereof for oily sludge drying described in the present invention are as follows:

[0047] (1) fly ash, its mass percentage composition is 60wt%;

[0048] (2) limestone, its mass percentage composition is 30wt%;

[0049] (3) gypsum, its mass percentage composition is 9wt%;

[0050] (4) auxiliary agent, the mass percentage of sodium lignosulfonate is 1wt%.

[0051] Add it into the stirring homogeneous kettle according to the above ratio, and fully mix and homogenize. The evenly mixed material is the oily sludge desiccant, called 2# desiccant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com