Drying treatment method of oil-containing sludge

A treatment method and sludge drying technology, which can be used in sludge treatment, water/sludge/sewage treatment, fixed/solidified sludge treatment, etc. Achieve the effect of no secondary pollution, high economic benefit and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

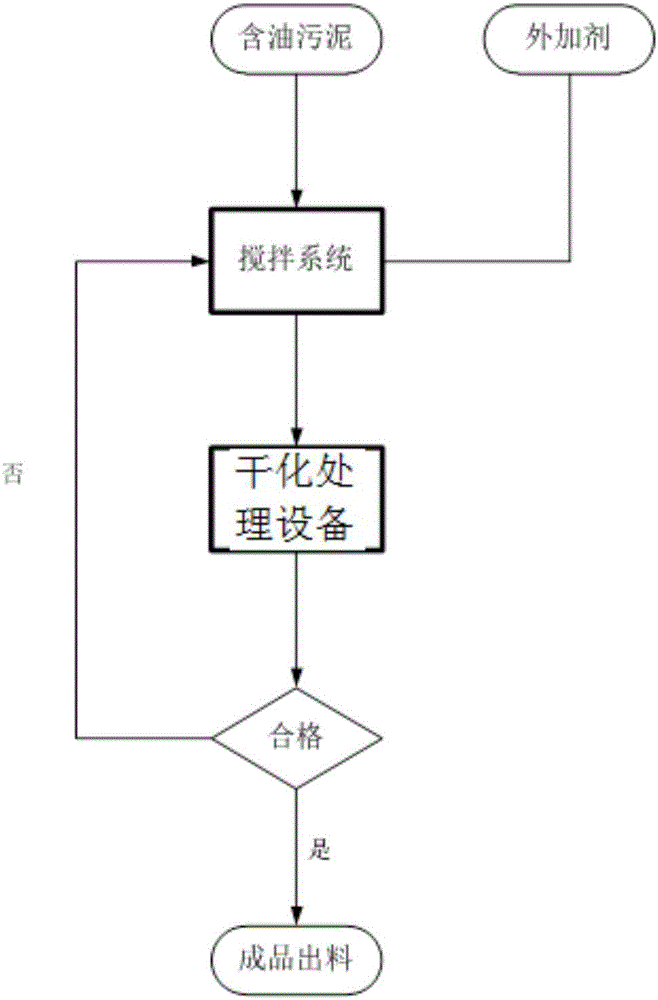

Method used

Image

Examples

example 1

[0039] The waste to be treated is oily sludge without mechanical treatment

[0040] 1) Determining the moisture content of the sludge to be treated in the oily sludge, the measurement result is 71.3%, by weight g, configuration modifier, ethylene triamine 65g, carbon powder 25g, sodium hydroxide 10g, sodium lignosulfonate 20g, ten Dialkyl sodium sulfate 5g, zeolite 5g, wood vinegar 5g;

[0041] 2) Transport the oily sludge to be treated to the oily sludge drying treatment equipment, start stirring, and at the same time start the dosing mechanism in the oily sludge drying treatment equipment, and add the modifier at a ratio of 20% by weight;

[0042] 3) The sludge to be treated is continuously stirred in the oily sludge drying treatment equipment. After the stirring is sufficient, the crushing mechanism is opened to crush the modified sludge, and the qualified products are screened and discharged to make fuel powder.

example 2

[0044] The waste to be treated is the oily sludge after being filtered by the plate and frame filter press

[0045] 1) Determination of the water content of the sludge to be treated in the oily sludge, the measurement result is 60%, by weight g, configuration improver, ethylene triamine and diethylene triamine 45g, carbon powder 30g, potassium carbonate and alum 10g, improve Natural diatomite 15g, fatty alcohol polyoxyethylene ether 20g, zeolite and diatomite 10g, plant polyphenol 8g;

[0046] 2) Transport the oily sludge to be treated to the oily sludge drying treatment equipment, start stirring, and at the same time start the dosing mechanism in the oily sludge drying treatment equipment, and add the modifier at a ratio of 10% by weight;

[0047] 3) The sludge to be treated is continuously stirred in the oily sludge drying treatment equipment. After the stirring is sufficient, the crushing mechanism is opened to crush the modified sludge, and the qualified products are scree...

example 3

[0049]The waste to be treated is hydrocarbon-containing sludge that has not been mechanically treated.

[0050] 1) Determination of the water content of the oily sludge to be treated, the measurement result is 75.7%, by weight g, configuration improver, m-phenylenediamine 70g, carbon powder and sawdust 25g, alum or potassium nitrate 5g, calcium lignosulfonate 5g, propylene glycol methyl ether acetate 12g, activated carbon powder 6g, wood vinegar and plant polyphenol 8g;

[0051] 2) Transport the oily sludge to be treated to the oily sludge drying treatment equipment, start stirring, and at the same time start the dosing mechanism in the oily sludge drying treatment equipment, and add the modifier at a ratio of 20% by weight;

[0052] 3) The sludge to be treated is continuously stirred in the oily sludge drying treatment equipment. After stirring for 5 minutes, the crushing mechanism is turned on to crush the modified sludge, and the qualified products are screened and discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com