Sludge drying full-automatic production line

A sludge drying, fully automatic technology, applied in sludge treatment, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc. The mud is not strong enough to achieve the effect of lightening the load, not easy to loosen, and setting reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings of the description.

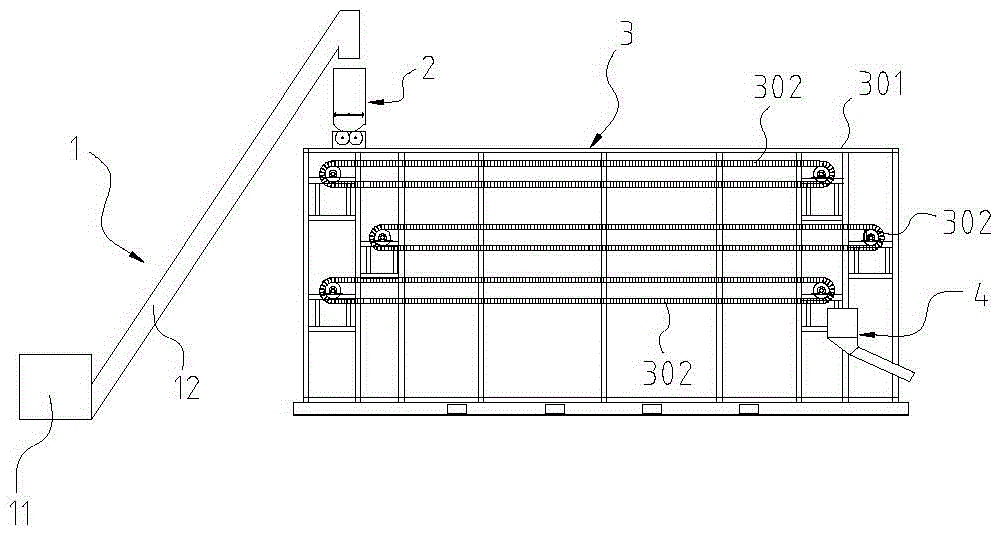

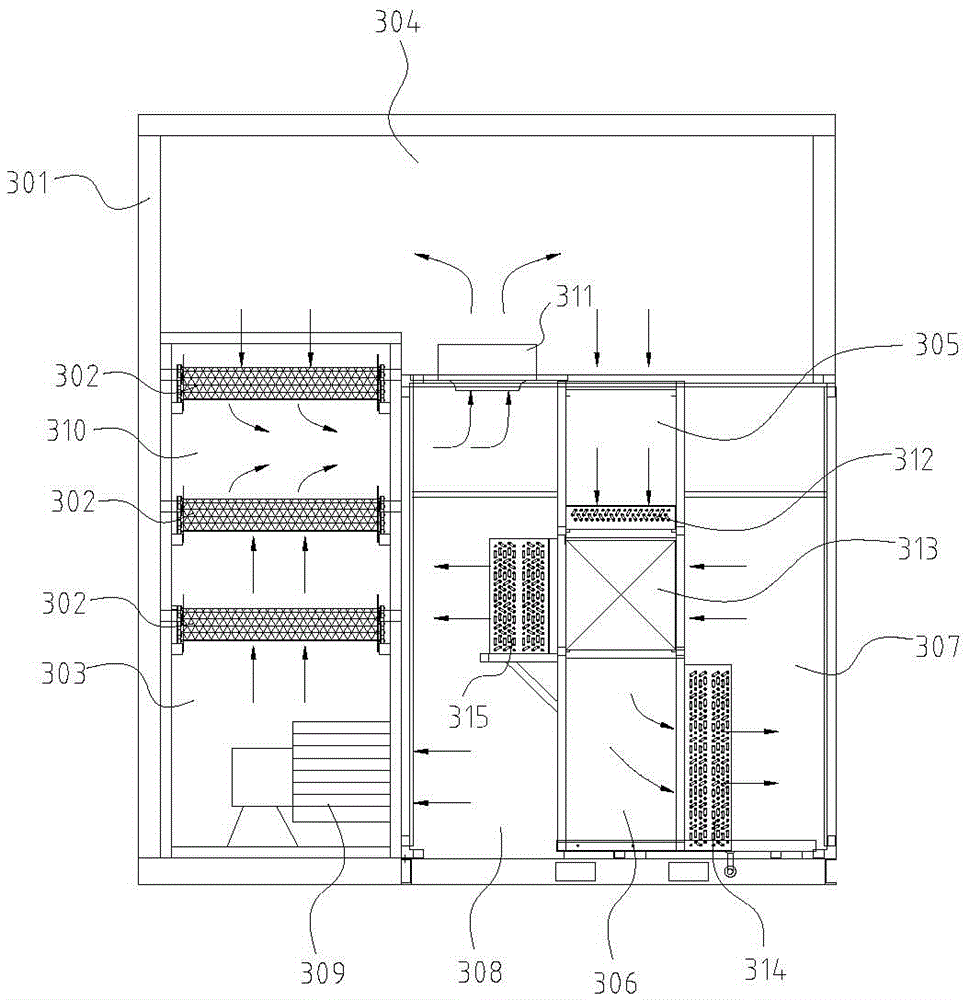

[0030] Such as figure 1 As shown, a fully automatic sludge drying production line includes a feeder 1, a sludge forming machine 2, a drying dehumidifier 3, and a discharger 4 in sequence according to the conveying direction of the material.

[0031] Such as figure 1 As shown, the feeder 1 includes a feed barrel 11 and a screw lifting mechanism 12, and the feed barrel 11 is docked with the sludge forming machine 2 through the screw lifting mechanism 12. The sludge forming machine 2 is set on the top of the drying dehumidifier 3, and the feeding barrel 11 is set at a lower position for the convenience of feeding, so the screw lifting mechanism 12 is needed to transport the material to the sludge forming machine 2. When the screw elevator is conveying the material, the material is chopped and decomposed by the agitation of the spiral blade.

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com