Arsenic-containing waste water treatment method and apparatus

A treatment method and wastewater technology, applied in the field of water pollution control, can solve the problems of secondary pollution, high cost, low efficiency, etc., and achieve the effects of reducing agglomeration, reducing toxicity, and speeding up the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Among them, the microwave catalyst is a microwave-absorbing material loaded with zero-valent iron, and the relative dielectric constant of the microwave-absorbing material is not less than 4, such as silicon carbide, activated carbon, biochar, ferrite, graphite, carbon black, iron minerals, etc. or manganese minerals. The function of the absorbing material in the present invention is to improve the absorbing performance of the zero-valent iron. When adopting different wave-absorbing substances and loading zero-valent iron as the microwave catalyst of the present invention, the specific loading and preparation methods are different. The method is prepared, and the silicon carbide is in the shape of a tube, a rod or a plate. Iron sheet is used as anode, silicon carbide is used as cathode, ferrous salt is used as electrolyte, and the silicon carbide microwave catalyst loaded with zero-valent iron is obtained after a constant current of 0.5-2A and energized for 10-40 minut...

Embodiment 1

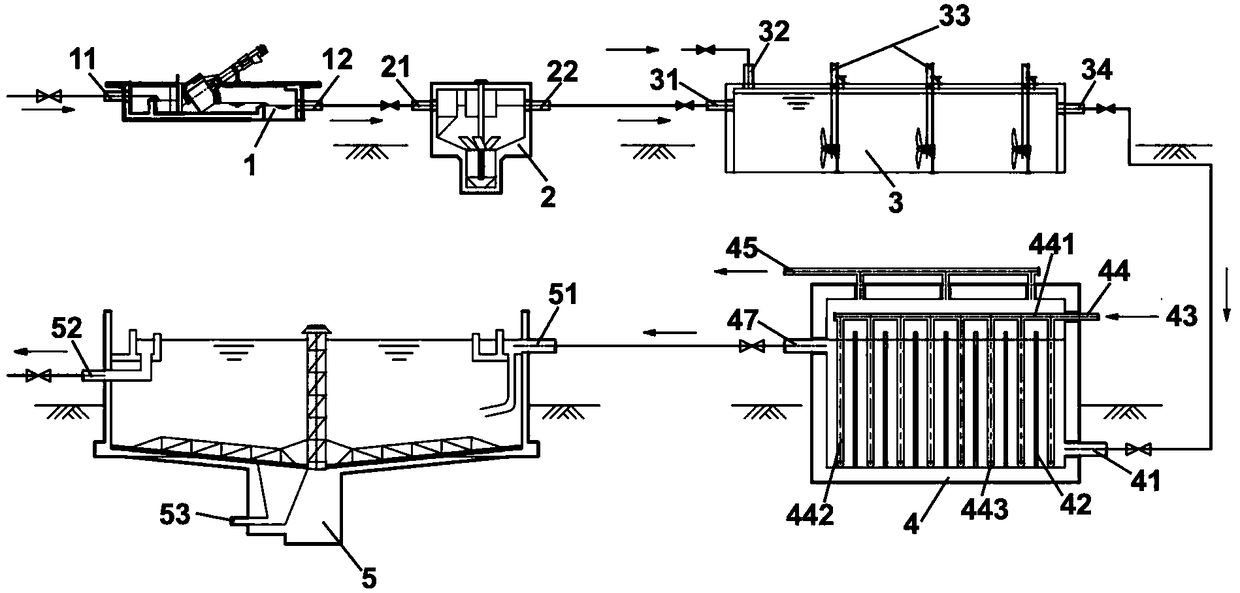

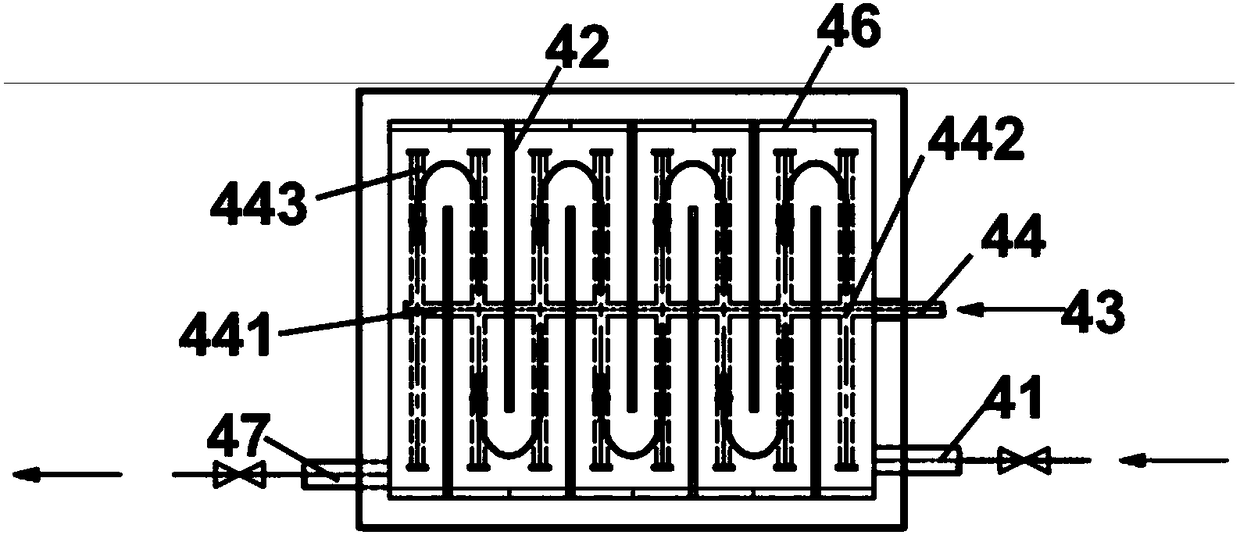

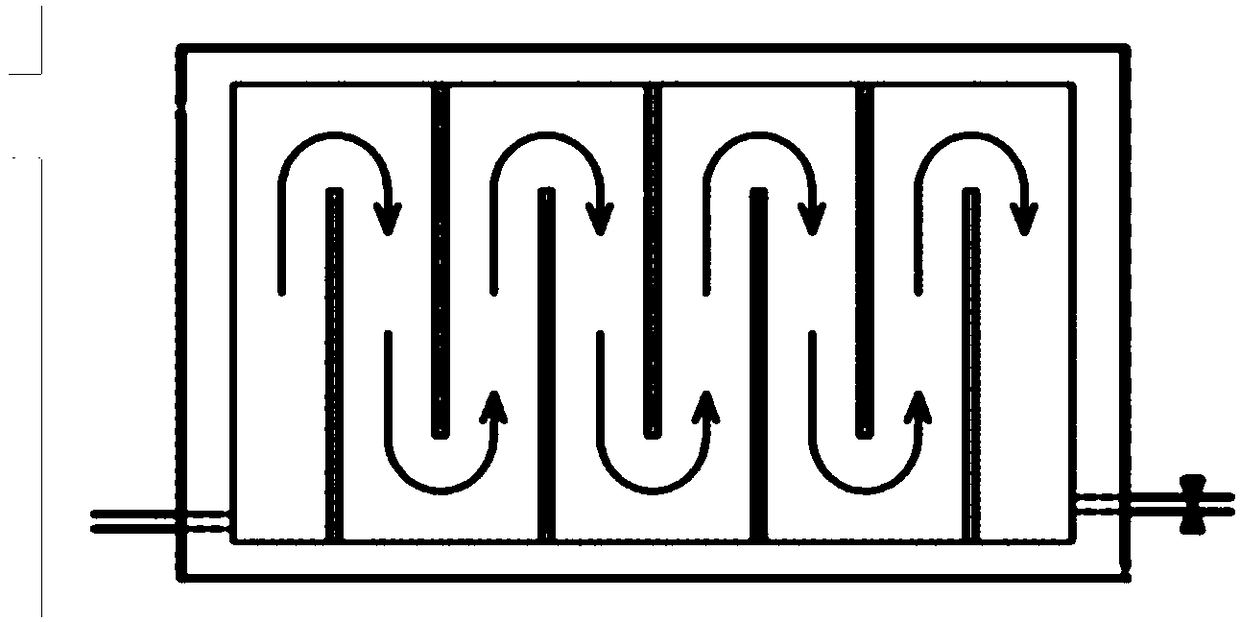

[0079] A kind of arsenic wastewater treatment device, such as figure 1 As shown, it includes a wastewater oxidation treatment section and a sludge solidification treatment section, wherein: the wastewater oxidation treatment section includes a grid pool 1, a swirling grit chamber 2, a regulating pool 3, a microwave reaction pool 4 and a secondary sedimentation pool 5.

[0080] The grid pool 1 includes a grid pool inlet 11 and a grid pool outlet 12; the grid pool 1 is used for preliminary filtration treatment of arsenic-containing wastewater, and the arsenic-containing wastewater enters the grid pool 1 from the grid pool inlet 11 and is filtered. After that, it flows out from the grid pool outlet 12.

[0081] The swirl grit chamber 2 includes the swirl grit chamber inlet 21 and the swirl grit chamber outlet 22, the grid cell outlet 12 communicates with the swirl grit chamber inlet 21, and the swirl grit chamber 2 is used to remove arsenic Sand particles in wastewater.

[0082] ...

Embodiment 2

[0095] The treatment of arsenic-containing wastewater using the arsenic-containing wastewater treatment device described in Example 1 comprises the following steps:

[0096] (1) Preparation of microwave catalyst: After SiC was cleaned 3 times with deionized water, it was placed in 1% HCl solution for 30 minutes, then it was taken out and cleaned 3 times with deionized water, and placed in an electric blast drying oven at 105 Dry at ℃ for 8 hours, take out, cool to room temperature, and set aside. Then 11.12gFeSO 4 ·7H 2 O was dissolved in 200 mL deionized water, and a little H was added 2 SO 4 prevent Fe 2+ Oxidized, prepare 0.20mol / L FeSO 4 The solution is an electrolyte. Electrodeposition was carried out with a DC stabilized power supply, the pretreated SiC was used as the cathode, the bright iron sheet was used as the anode, the constant current was 1.00A, and Fe / SiC was obtained after 20 minutes of electrification.

[0097] (2) Oxidation and precipitation of wastewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com