Waste gas recycling system for organic waste biological drying process

A technology of organic waste and biological drying, applied in chemical instruments and methods, heat exchangers, lighting and heating equipment, etc., can solve the problems of reducing internal air temperature, small temperature difference, and inconspicuous exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

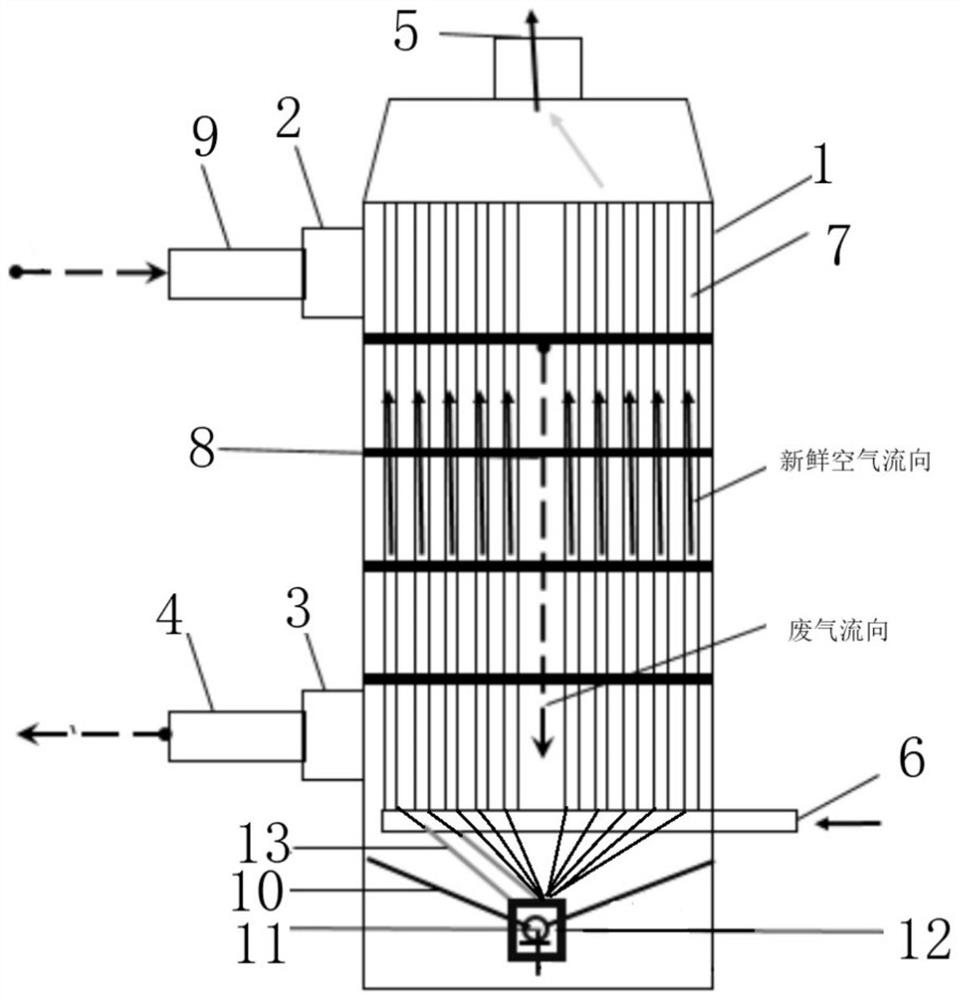

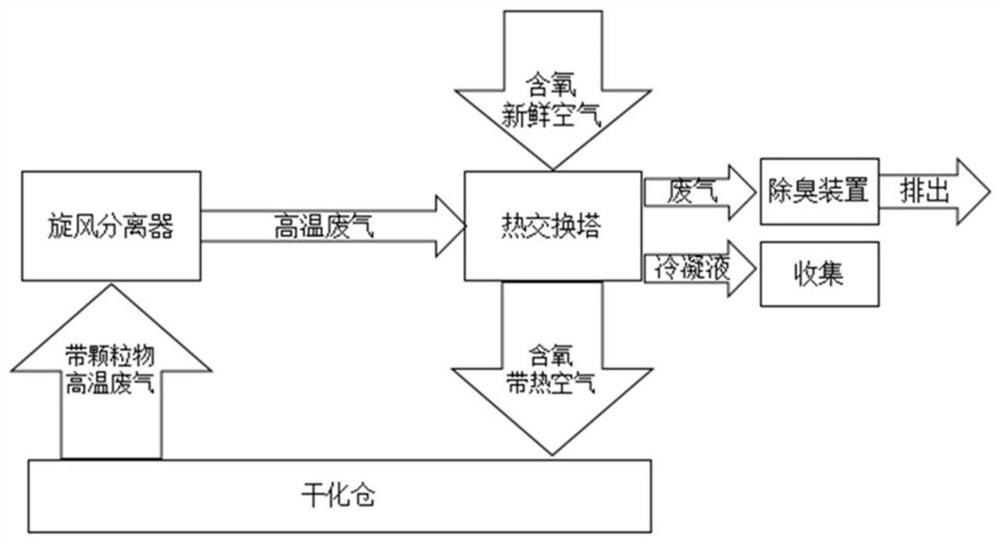

[0025] like figure 1 The waste gas recycling system shown for the biological drying process of organic waste includes:

[0026] A vertical heat exchange tower body 1, the outer shell is made of 304 stainless steel, which has good anti-corrosion performance.

[0027] The upper part of one side of the heat exchange tower body 1 is provided with a waste gas inlet 2 connected to the exhaust port of the drying reactor, and the lower part of the side is provided with a waste gas outlet 3, which is directly discharged to the outside. The waste gas inlet 2 is provided with Cyclone separator 9, the waste gas outlet 3 is provided with a deodorizer 4, the waste gas is introduced through the air induction pipe, and the deodorized waste gas is discharged from the exhaust pipe, when the air intake speed is 50m 3 / h, the dust removal effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com