Chrysanthemum drying method with shape keeping and brown stain preventing functions

An anti-browning and chrysanthemum technology is applied in the directions of drying, drying solid materials, heating to dry solid materials, etc., and can solve the problems of reducing drying temperature, prone to browning, affecting the appearance and commodity value of chrysanthemum brewing, etc. To achieve the effect of shortening the cycle, conducive to maintenance, and prolonging the preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The comparative example of the present invention is a chrysanthemum drying method that does not carry out steam inactivation and only carries out heat pump drying, and its specific operation is as follows:

[0044] 1) The picked organic chrysanthemums are graded and selected, and then arranged manually;

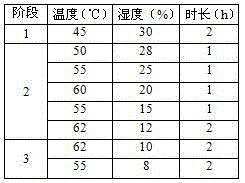

[0045] 2) Heat pump drying: It is carried out in three stages. The first stage: slow drying at low temperature and high humidity for 1 hour, to preserve the quality of edible flowers to the greatest extent; the second stage: gradually increase the temperature and reduce humidity and dry for 8 hours, while ensuring product quality. At the same time, speed up the drying rate; the third stage: drying at high temperature and low humidity for 3 hours to maximize the drying rate and save energy; the drying parameters of the heat pump are shown in Table 3:

[0046] Table 3 Parameter setting of heat pump drying (1)

[0047]

[0048] 3) The dried organic chrysanthemums are ...

Embodiment 2

[0052] Add steam inactivation treatment after the method step 2) of comparative example 1, other methods are the same, the concrete operation of steam inactivation is:

[0053] 3) Steam inactivation: put the dried chrysanthemums in step 2) into a sealed glass container, then put the sealed glass container into a steam pressure cooker, and treat it at a steam temperature of 65°C for 15 minutes.

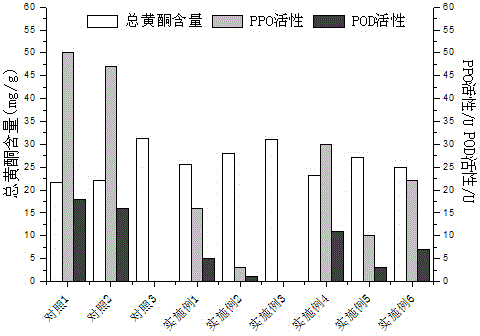

[0054] For the chrysanthemums prepared by the chrysanthemum drying method described in Comparative Example 2, the contents of polyphenol oxidase (PPO) and peroxidase (POD) in chrysanthemums were 47U and 16U respectively, and the total flavonoids in the sample extract The content is 22.1mg / g. The browning phenomenon is still obvious when chrysanthemum is brewed, especially when the water temperature is lower than 80°C, the browning is extremely obvious.

Embodiment 3

[0056] After the method step 2) of comparative example 1, steam inactivation treatment, other methods are the same, and the specific operation of steam inactivation is:

[0057] 3) Steam inactivation: put the dried chrysanthemums in step 2) into a sealed glass container, then put the sealed glass container into a steam pressure cooker, and treat it at a steam temperature of 100°C for 3 minutes.

[0058] For the chrysanthemums prepared by the chrysanthemum drying method described in Comparative Example 2, the contents of polyphenol oxidase (PPO) and peroxidase (POD) in the chrysanthemums were 0 U and 0 U respectively, and the total flavonoids in the sample extract The content is 31.3mg / g. There is no browning phenomenon when chrysanthemum is brewed. But the curly degree of dried chrysanthemum that obtains increases significantly, has influenced dry chrysanthemum profile, compares with the dry chrysanthemum profile that comparative example 1 prepares as figure 1 shown.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com