Sludge bio-drying treatment technology

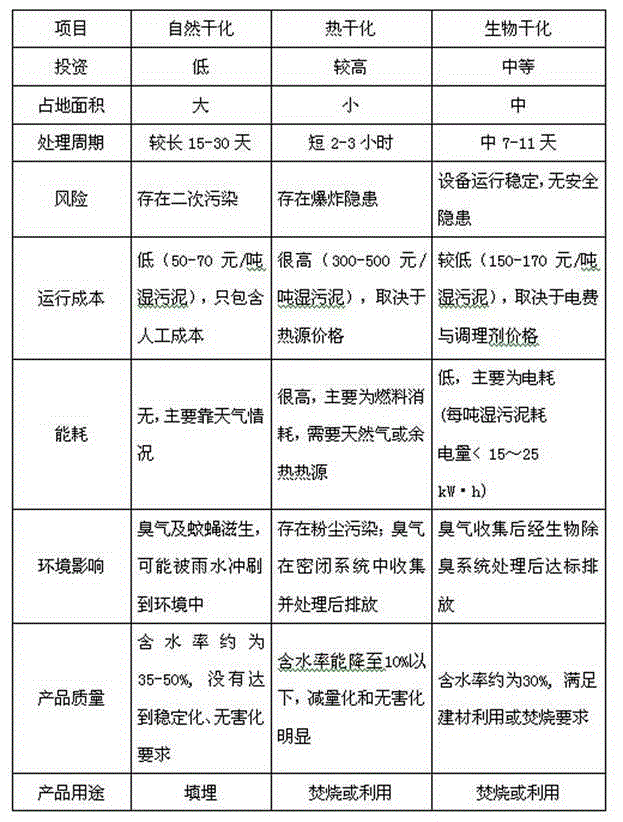

A biological drying and sludge technology, applied in biological sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of environmental pollution, high power consumption, high cost, etc., to avoid environmental pollution and improve utilization rate , Improve the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The sludge biological drying treatment of the present invention is a drying treatment process of fresh sludge with a water content of 76% to 84% after concentration treatment. In this example, 3000 kg of concentrated fresh sludge was taken directly from the domestic sewage treatment plant, and its moisture content was detected to be 80%. For the indicators of the fresh sludge, please refer to Table 7; in addition, it also contains a large amount of organic matter, coliform bacteria, insect eggs, etc.

[0057] name Mercury (Hg) Arsenic (As) Lead (Pb) Cadmium (Cd) Chromium (Cr) content 0.322 10.26 60.2 1.23 82.6

[0058] The biological drying treatment of sludge of the present invention comprises the following steps:

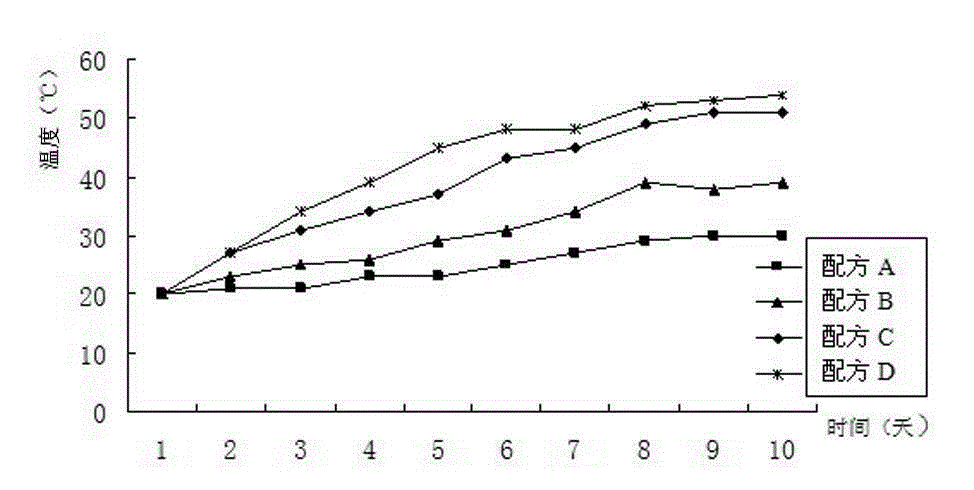

[0059] a. Deploy fresh sludge moisture content: Stir and mix the fresh sludge with a moisture content of 80% and the base material with a moisture content of 30% at a weight ratio of 1:1.5 to obtain a mixture with a moistu...

Embodiment 2

[0067] The sludge biological drying treatment of the present invention is a drying treatment process of fresh sludge with a water content of 76% to 84% after concentration treatment. In this example, 5000 kg of concentrated fresh sludge was taken directly from the domestic sewage treatment plant, and its water content was 82% after testing. The indicators of the fresh sludge are roughly the same as those in Table 7 above. The biological drying treatment of sludge of the present invention comprises the following steps:

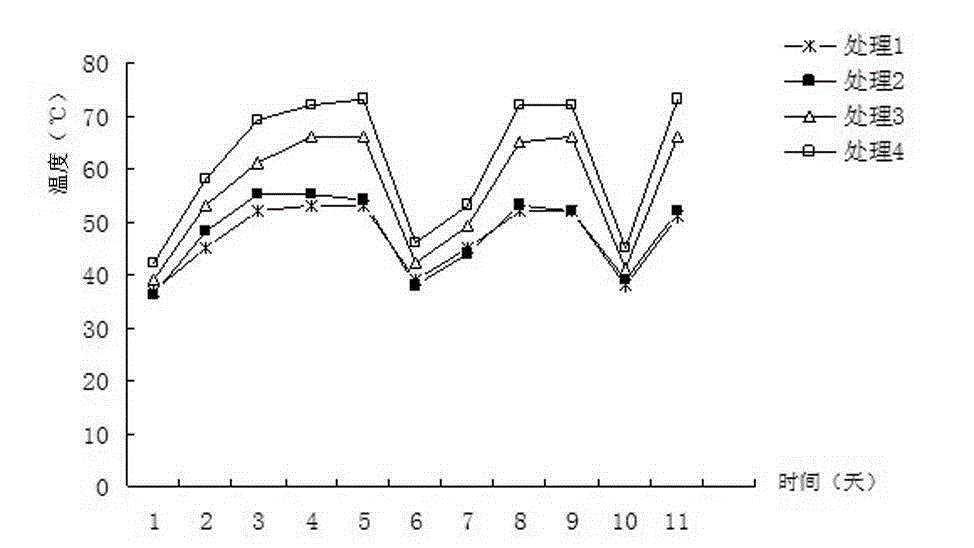

[0068] a. Deploy fresh sludge moisture content: Mix 3000kg of fresh sludge with a moisture content of 82% and the base material with a moisture content of 30% in a weight ratio of 1:1.6 to obtain a mixture with a moisture content of 50%. The base material selected in this example is the dried sludge in Example 1, with a moisture content of 30% and a weight of 4800 kg. According to theoretical analysis, the moisture content after mixing the fresh sludge and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com