Dredged sediment dewatering and drying stockyard and establishment method thereof

A technology for dredging sediments and storage yards, which is applied in the field of environmental engineering, can solve the problems of limiting the bearing capacity of sediment storage yards and the inability to further reduce the moisture content of sediments, so as to shorten the drying period of sediments and improve the drying rate of dehydration. The effect of increasing the speed and increasing the air circulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

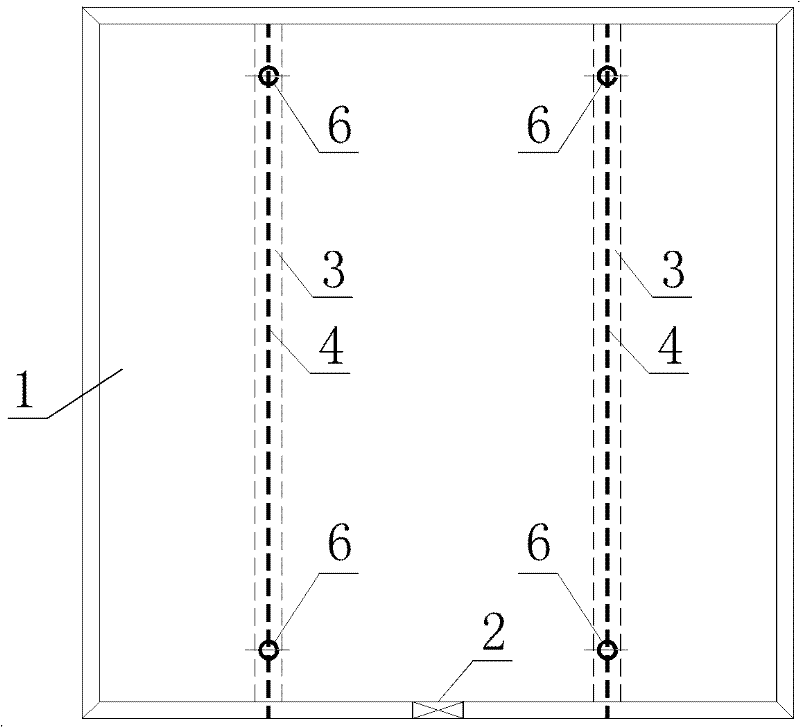

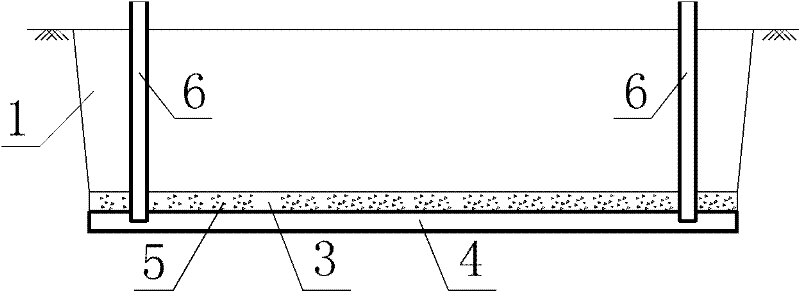

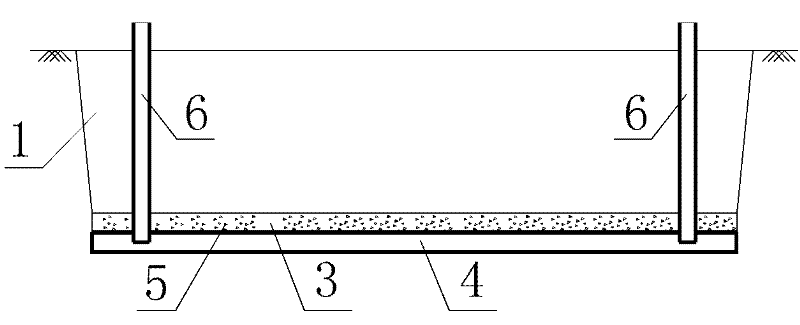

[0038] Dredging the sediment of a black and odorous river in Minhang District, Shanghai. Build a dredged bottom mud stockpile 1 beside the river channel for receiving the dredged bottom mud. The sediment dehydration and drying method adopts a two-stage mixed reaction deodorization and dehydration method; the first plane size of the storage yard is 20x20m, and the depth is 3m. Two drainage ditches 3 are set at the bottom of the storage yard 1 with a distance of 10m. The width of the drainage ditches 3 is 0.4m and the depth is 0.4m. The drainpipe 4 placed therein has a diameter of 200mm, and the laying slope of the drainpipe 4 is 0.5%. A natural gravel water seepage layer with a particle size of 10-20 mm is laid between the drain pipe 4 and the drain ditch 3 . A vertical conduit 6 with a diameter of 400mm is embedded at the two ends of the two drainage pipes 4, extending to the top of the yard 1, and a submersible pump is placed in the vertical conduit 6 to discharge the remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com