High-efficiency tea leaf dehydration device

A dehydration device and tea technology, which are applied to heating devices, pre-extraction tea treatment, sieves, etc., can solve problems such as unfavorable water vapor emission, and achieve the effects of increasing dehydration drying speed, improving vibration effect, and improving drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

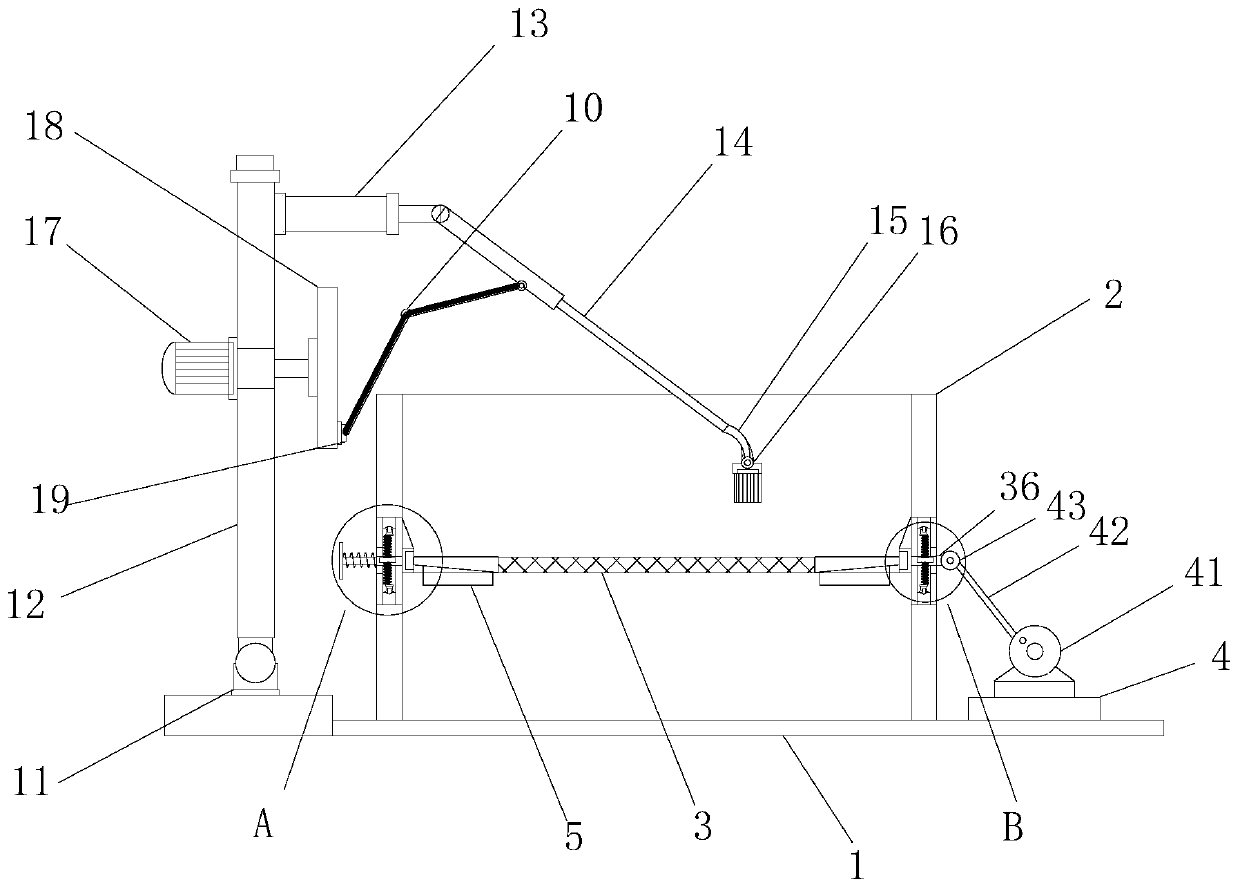

[0027] see figure 1 , a high-efficiency tea dehydration device, including a base plate 1, an operation box 2 is installed on the base plate 1, a dehydration screen 3 is installed horizontally in the operation box 2, and a frame 31 is installed on the four sides of the dehydration screen 3 , The frame 31 is used to limit the tea leaves to prevent the tea leaves from being screened out.

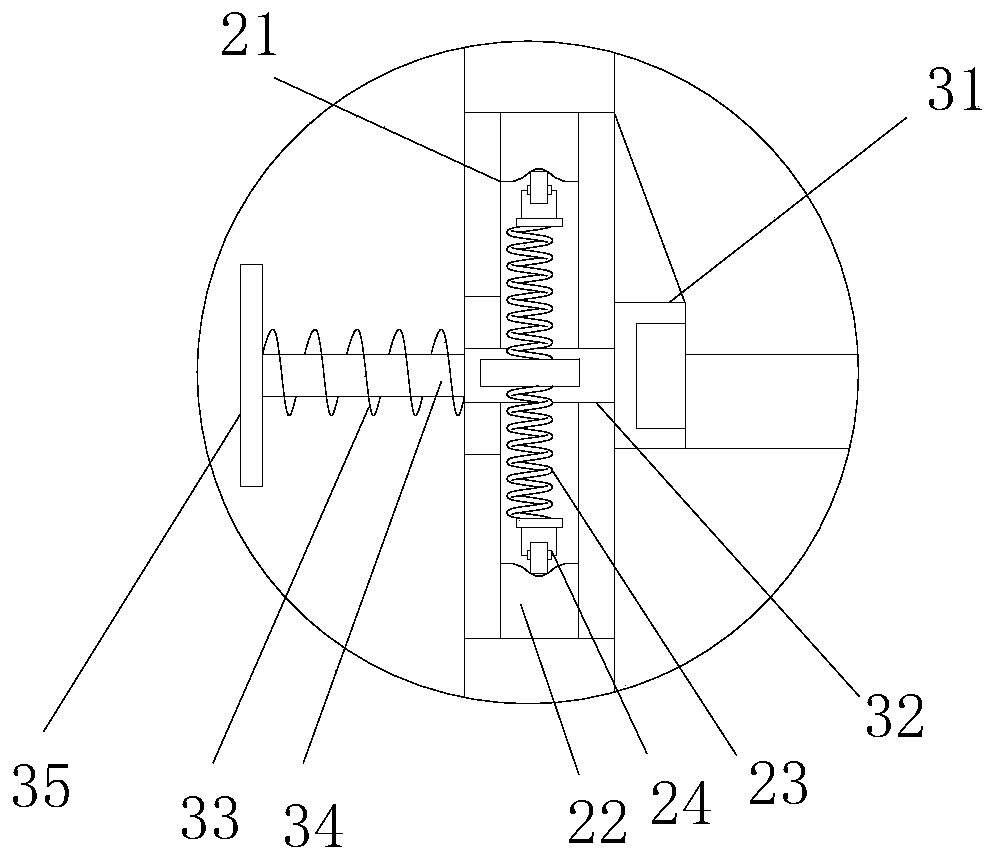

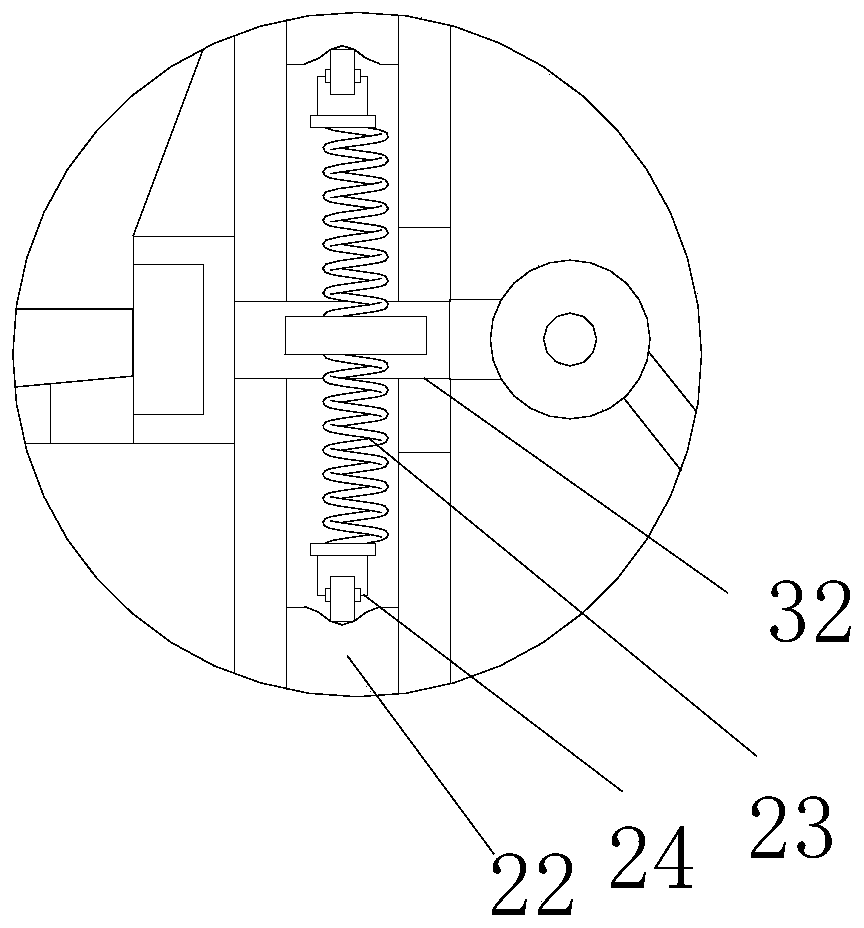

[0028] see figure 1 and figure 2 , the outer ends of the left and right frame 31 are all externally connected to the limit plate 32, the side wall of the operation box 2 is provided with a limit groove 21, and the limit plate 32 is all pierced in the corresponding limit groove 21, The limiting plate 32 on one side is externally connected to the pull rod 36, the base plate 1 is equipped with a work frame 4, the drive plate 41 is installed on the work frame 4, and the pull rod 36 is connected with a drive rod 42 through a movable bolt 43, so One end of the transmission rod 42 is connected to ...

Embodiment 2

[0033] see figure 1 ,, this embodiment is further optimized as Embodiment 1. On the basis of it, a support base 11 is installed on the base plate 1, a support frame 12 is installed on the support base 11, and a horizontal frame 12 is installed on the support frame 12. Frame 13, said cross frame 13 is equipped with operating bar 14 by bending bolt, and the bar end of said operating bar 14 is equipped with bending bar 15, and the bottom end of said bending bar 15 is equipped with turning brush 16, and said turning The brush 16 adopts soft brush material, and the material turning motor 17 is installed on the support frame 12, and the driving end of the material turning motor 17 is equipped with a vertical turntable 18, and the outer edge of the vertical turntable 18 is equipped with a connection A bolt 19 , the connection bolt 19 is connected to the working rod 14 through a bent connecting rod 10 .

[0034] After the drying of the water quality on the surface of the tea leaves i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com