Construction method of stock dump capable of accelerating dehydration and drying process of dredging deposited sludge

A technology for dredging sediment and a construction method, which is applied in construction, soil protection, infrastructure engineering, etc., can solve the problems of difficult discharge of sediment in the yard, long drying period of sediment, and difficulty in reaching bearing capacity of sediment. To achieve the effect of increasing the drainage head, simple processing, and improving the drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following examples are not intended to limit the present invention.

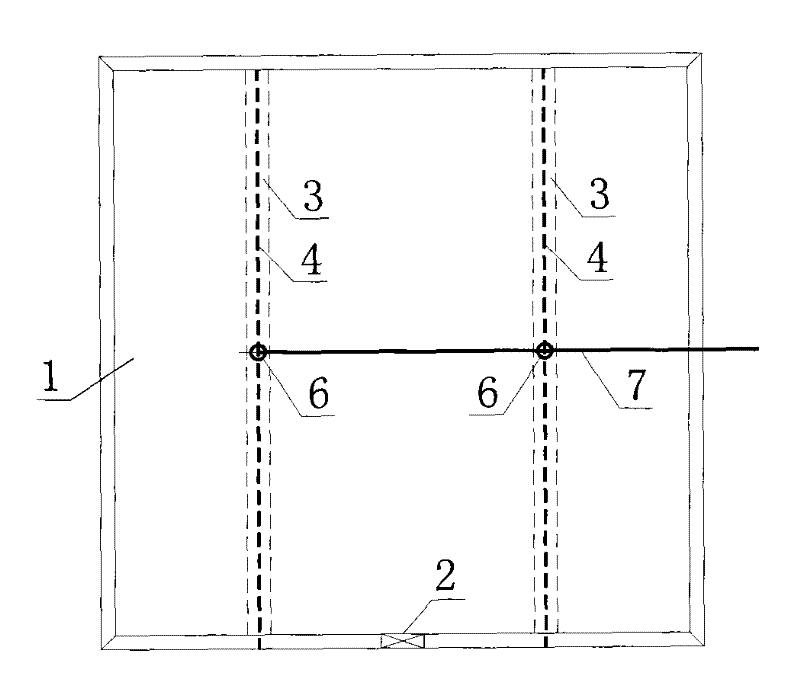

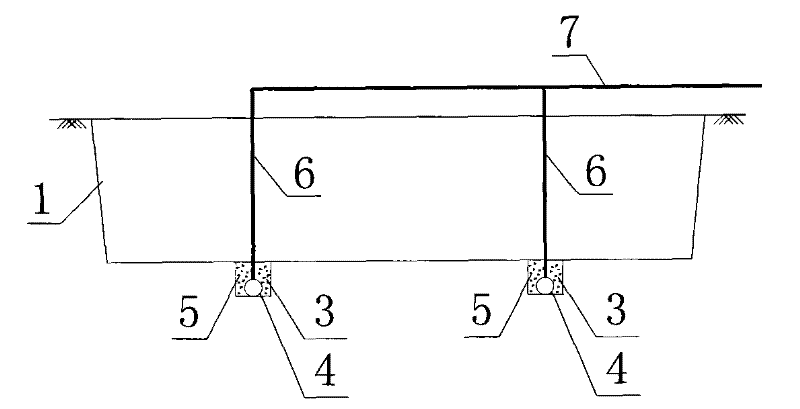

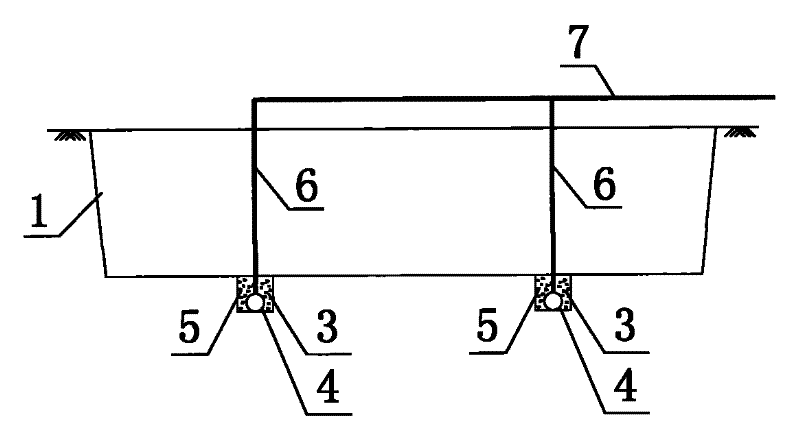

[0028] The yard structure that the present invention builds is as figure 1 with figure 2 As shown, it includes the upper drainage outlet 2 of the yard drainage system, the lower drainage ditch 3, the drainage pipe 4 placed in the drainage ditch, the seepage gravel 5 laid in the drainage ditch, the vertical conduit 6, and the collection pipeline 7 of the vertical conduit , the summarizing duct 7 of the vertical conduit is connected to an external vacuum system.

[0029] Such as figure 1 , figure 2 As shown, the present invention builds a drainage system in the bottom mud stockyard, and the drainage system is composed of an upper drainage port 2 and a lower drainage ditch 3 .

[0030] Firstly, a drainage outlet 2 is set on one side of the sediment sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com