Garbage drying treatment system and method

A processing system and technology for waste drying, applied in combustion methods, drying, dryers, etc., can solve the problems of reducing the area of waste drying, shortening drying cycle, and long drying cycle, so as to shorten the waste The effect of drying cycle, shortening drying cycle and reducing drying cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

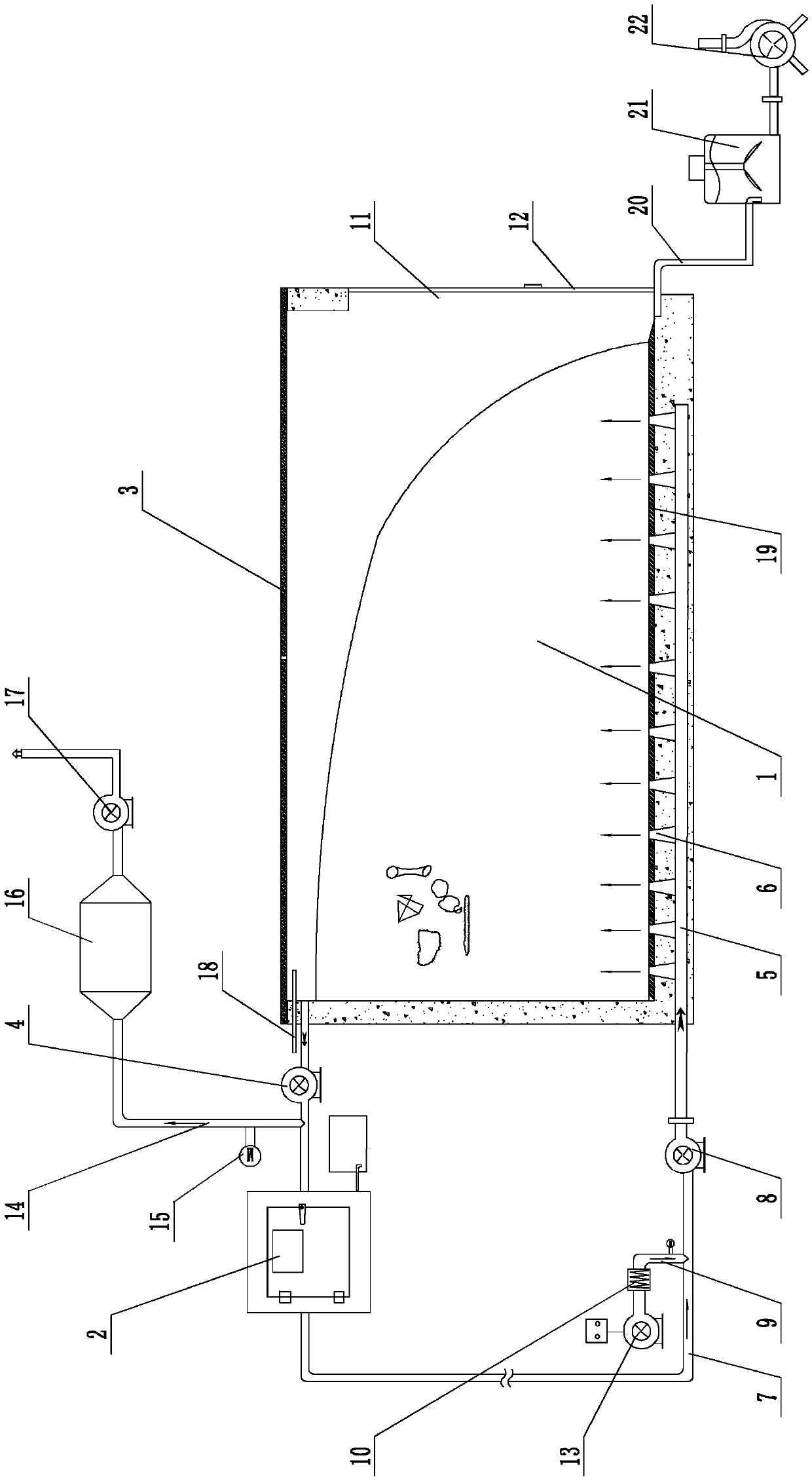

[0025] Embodiment 1: A kind of rubbish drying processing system (see attached figure 1 ), including drying bin 1, dehumidification heat pump 2, solar power generation panel 3 installed on the top of the drying bin to supply power to the entire garbage drying treatment system, a sealing ring is set between the solar power generation board and the top of the drying bin, and the solar power generation Connect the photovoltaic controller, battery, and inverter, and the current output by the inverter supplies power to the entire garbage drying treatment system. The position close to the upper end of the drying chamber is connected to the exhaust fan 4, and the dehumidification heat pump is connected to the exhaust fan. The ventilation pipe 5 is installed at the bottom of the drying chamber, and a number of ventilation nozzles 6 for spraying air into the drying chamber are installed on the ventilation pipe. Between the ventilation pipe and the dehumidification heat pump The hot air ...

Embodiment 2

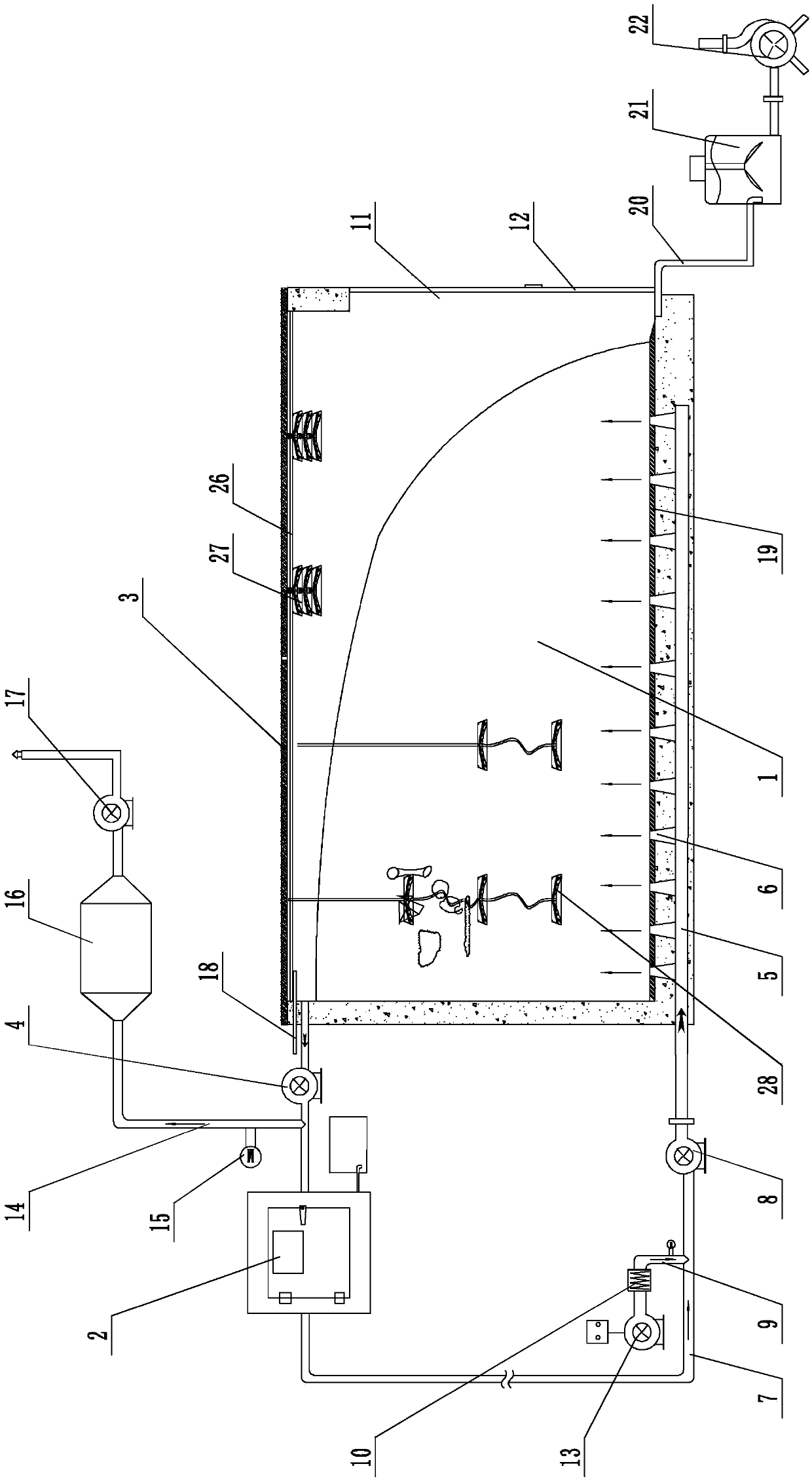

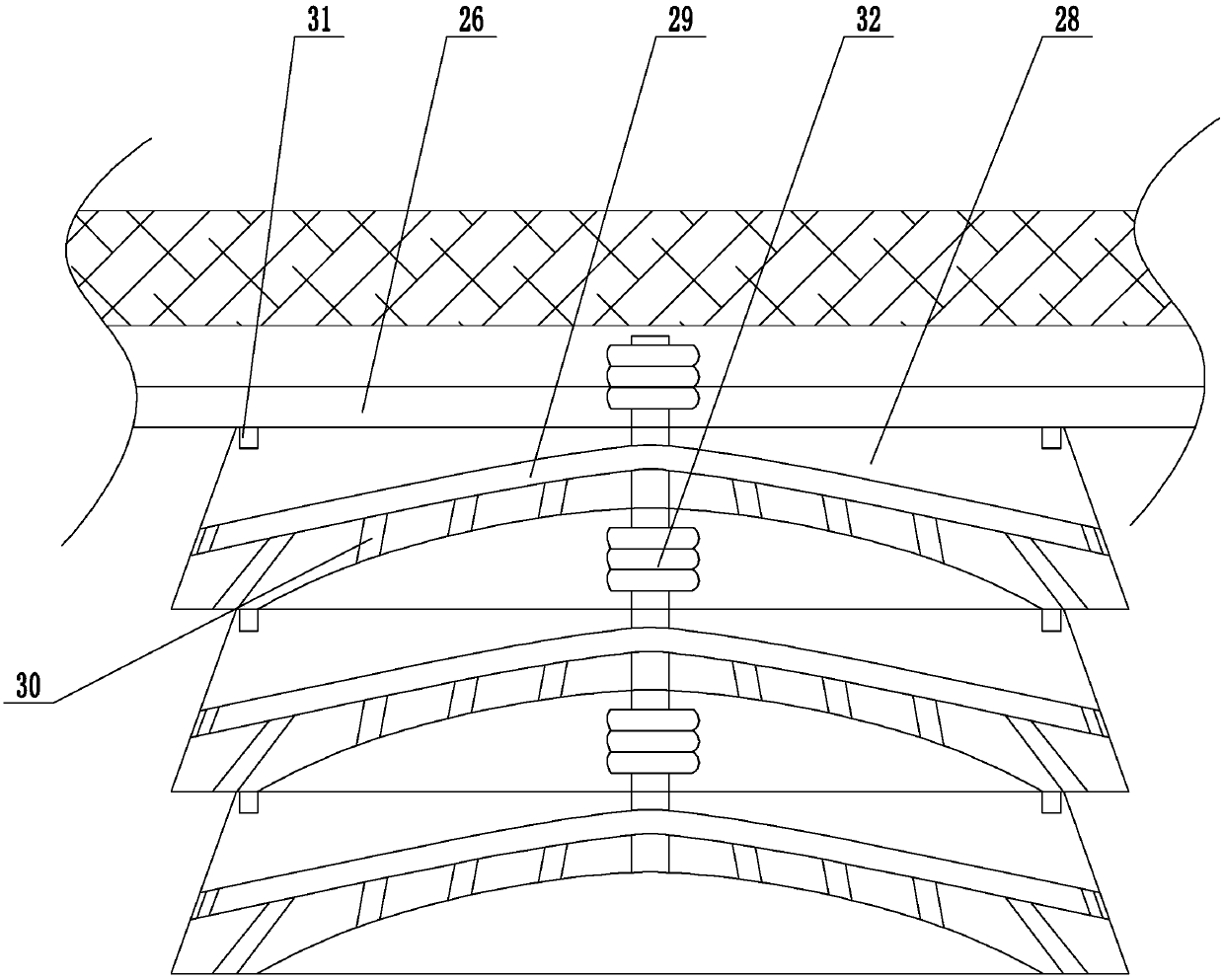

[0027] Embodiment 2: a kind of rubbish drying processing system (see attached figure 2 , attached image 3 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, a bracket 26 is installed near the upper end of the drying bin, and a number of ventilation assemblies 27 are installed on the bracket, and the ventilation assembly includes several ventilation cranes stacked up and down together. Block 28, ventilation cavity 29 is provided in the ventilation hanging block, the lower surface of the ventilation hanging block is a concave arc-shaped surface structure, and several ventilation holes 30 communicated with the ventilation cavity are provided on the lower surface and the side of the ventilation hanging block. The upper surface of the block is provided with several electromagnets 31 near the outer edge, and the adjacent two ventilation hanging blocks are attracted together by electromagnets. The ventilation hose 32 communicated w...

Embodiment 3

[0029] Embodiment 3: a kind of rubbish drying treatment system (see attached Figure 4 , attached Figure 5 ), its structure is similar to that of Embodiment 2, the main difference is that in this embodiment, the pressure plate 33 is hinged on both sides of the drying chamber near the door opening, the pressure plate is inclined upward toward the door opening, and the bottom of the drying chamber is installed between the pressure plate and the drying chamber. Positioning spring 34, an installation chamber 35 is provided at the bottom of the drying chamber close to the door opening, a driving gear 36 is installed in the installation chamber, lifting racks 37 are installed on the left and right sides of the chamber door, and the lower surface of the pressure plate near the upper end is movably connected to push the rack 38. The pushing rack and the lifting rack are respectively arranged on the left and right sides of the driving gear. Both the pushing rack and the lifting rack a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com