Bubbling baysalt device applied to seawater shoal

A seawater and bubbling technology is applied in the field of devices for bubbling and drying salt in seawater shoal, which can solve the problems of carbon nanotube processing, separation and recovery difficulties, carbon nanotubes being easily swept away by wind, and large power consumption for drying salt, etc. Achieve the effect of realizing automatic operation and control, increasing the gas-liquid two-phase mass transfer area, and shortening the salt drying cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

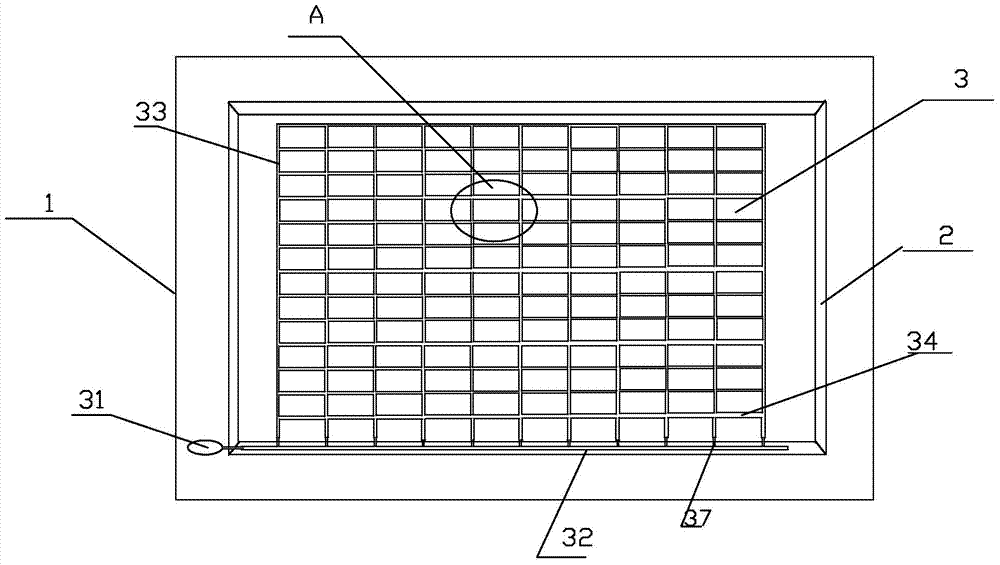

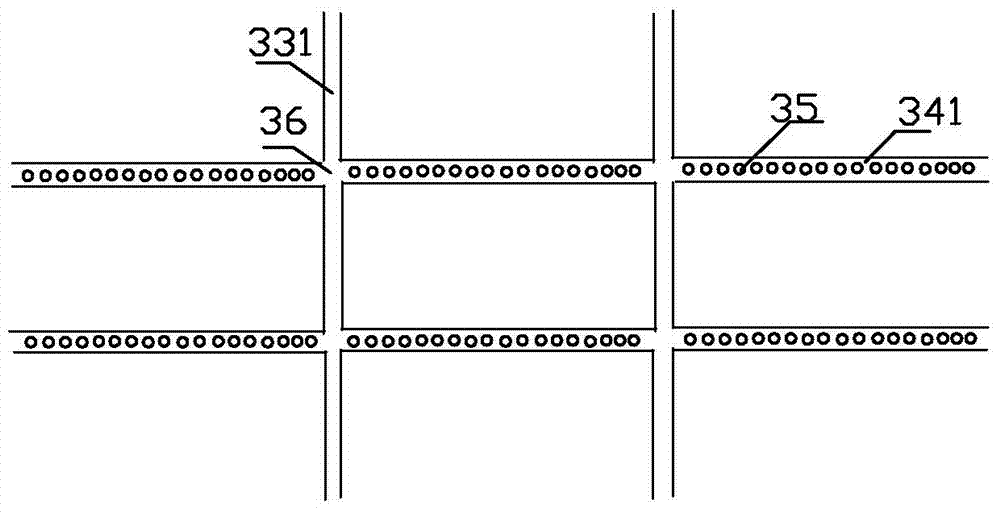

[0028] see figure 1 The device for bubbling and sunning salt in seawater shoals provided by the embodiment of the present invention is arranged for use in existing salt pans, and includes bubbling tube arrays, air pipes 32, blowing equipment 31, and an automatic environmental monitoring and control system (Fig. Not shown in), at least one layer of anti-seepage black film 1, fillers, etc., the above components will be described one by one below.

[0029] The anti-seepage black film 1 is laid on the bottom of the salt pan to prevent seawater from seeping into the salt pan and improve the utilization rate of light. It can be laid in multiple layers, such as two or three layers. In this embodiment, the anti-seepage black film 1 is a black high-density polyethylene anti-seepage film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com