Advanced sludge treatment equipment and using method thereof

A technology for advanced treatment and sludge, applied in the direction of sludge treatment, water/sludge/sewage treatment, special treatment targets, etc., can solve the problems of difficult power supply, complicated process, high cost, etc., and achieve improved dehydration effect and sludge properties Stable, easily crushable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

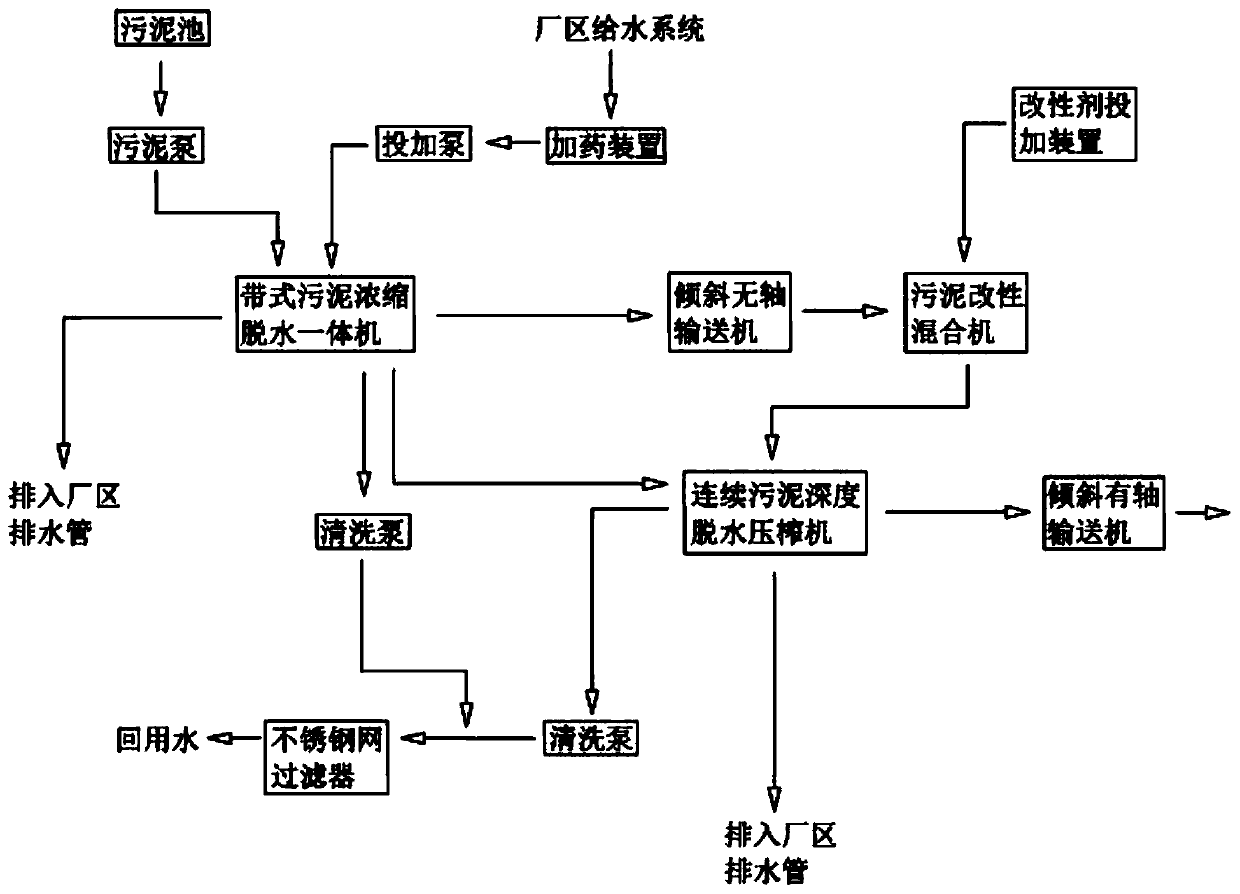

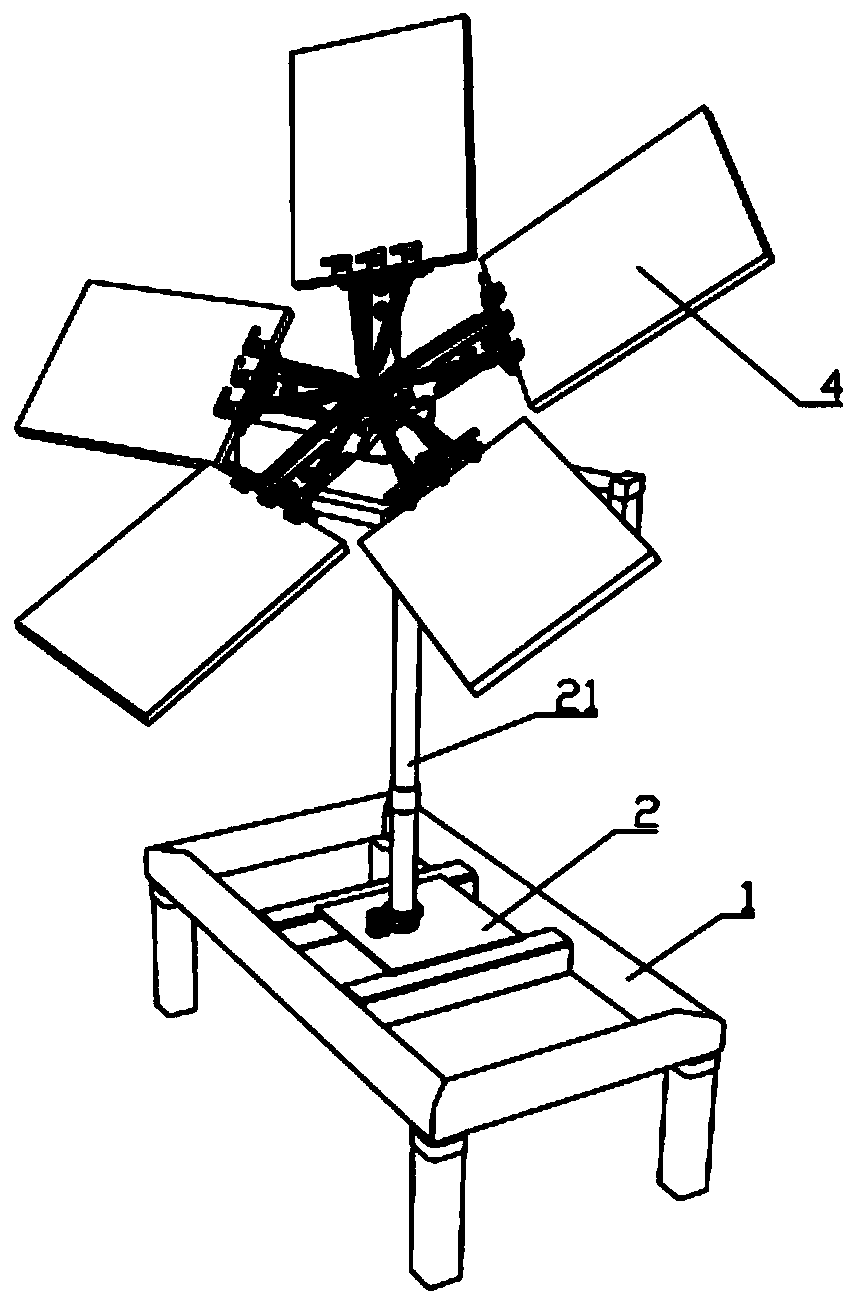

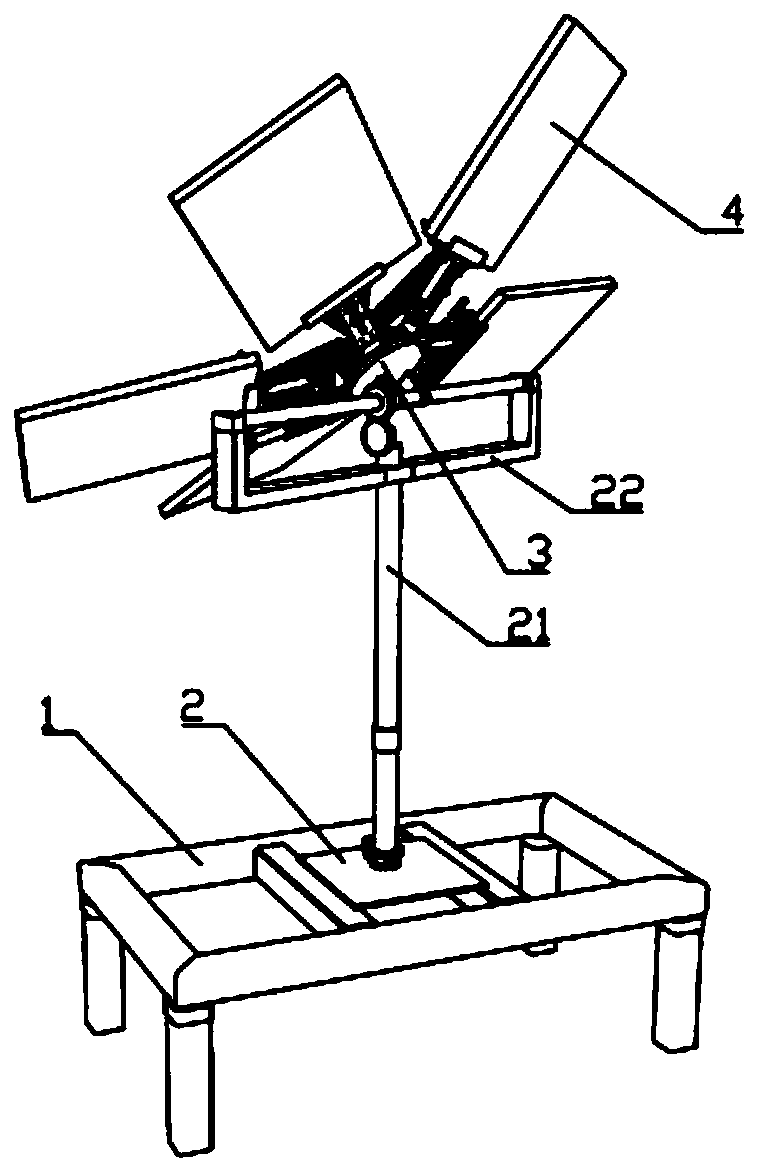

[0047] like Figure 1-Figure 10 As shown, the sludge advanced treatment equipment of the present invention includes a solar power supply mechanism, a sludge tank, a sludge pump, a belt sludge concentration and dehydration integrated machine, a dosing device, a dosing pump, an inclined shaftless conveyor, and a sludge Modified mixer, modifier dosing device, continuous sludge deep dewatering press, inclined shaft conveyor, cleaning pump and stainless steel mesh filter;

[0048] The output end of the solar power supply mechanism is respectively connected with the sludge pump, the belt sludge thickening and dewatering integrated machine, the dosing pump, the inclined shaftless conveyor, the sludge modification mixer, the continuous sludge deep d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com