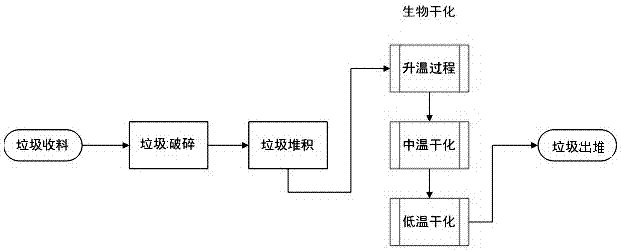

Intermediate-temperature drying method and device for biological film of garbage

A bio-drying and bio-film technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve the problems of negative environmental impact, low drying efficiency, etc., and achieve increased calorific value and high operating costs. , the effect of reducing the difficulty level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

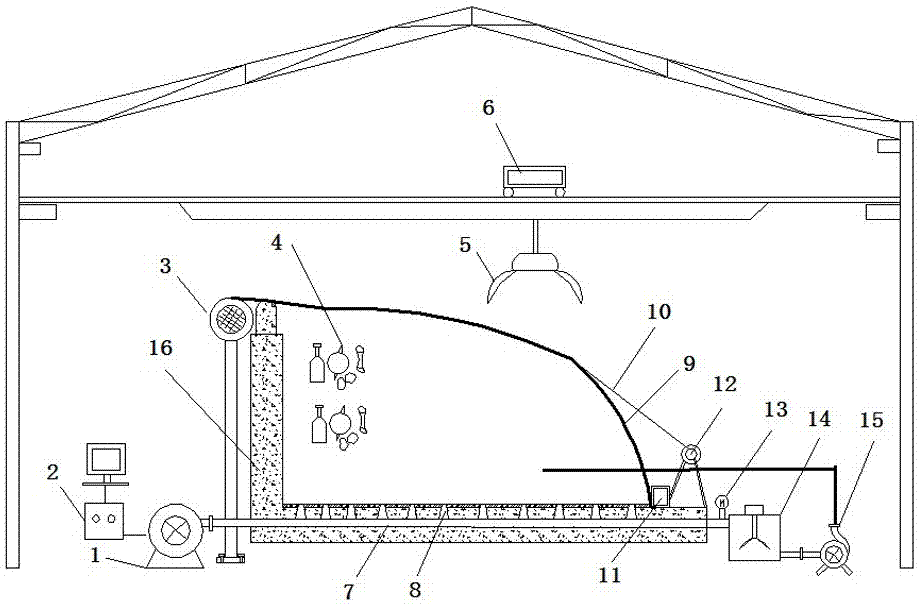

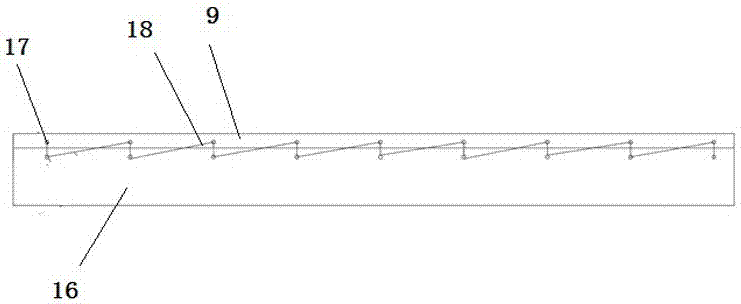

[0036] Example: A medium temperature biofilm drying device for garbage treatment, such as figure 2 Shown. The device includes a biological drying chamber 16, and an impermeable board is laid on the bottom surface of the biological drying chamber. The biological drying silo 16 is a square biological drying silo. Three sides of the biological drying silo are provided with walls, one side is an open side, and the top of the biological drying silo is open. The biological drying silo accumulates coarsely broken garbage 5, garbage The upper part is covered with a biological drying film 9 which is a high air permeability ePTFE biological drying microporous membrane. The outer side of the top wall of the biological drying chamber opposite to the opening side is provided with a film rolling mechanism 4 for winding the biological drying film. The opening side of the biological drying chamber is provided with a strip for pressing the biological drying film against the bottom surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com