Gasification system of garbage and organic waste and device thereof

A technology of organic waste and gasification system, which is applied in the field of waste gasification equipment, and can solve problems such as low calorific value, high water content, and high chlorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

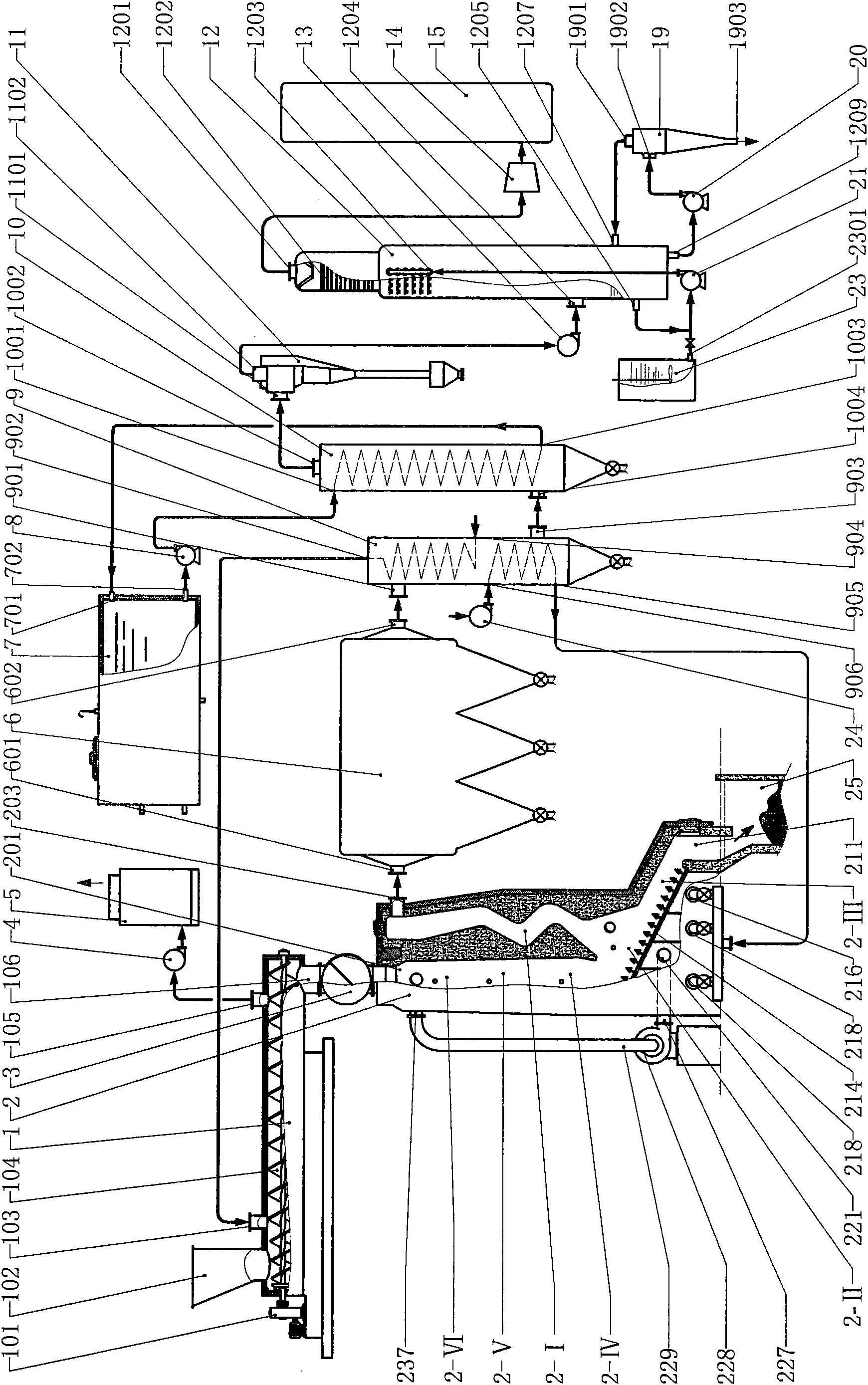

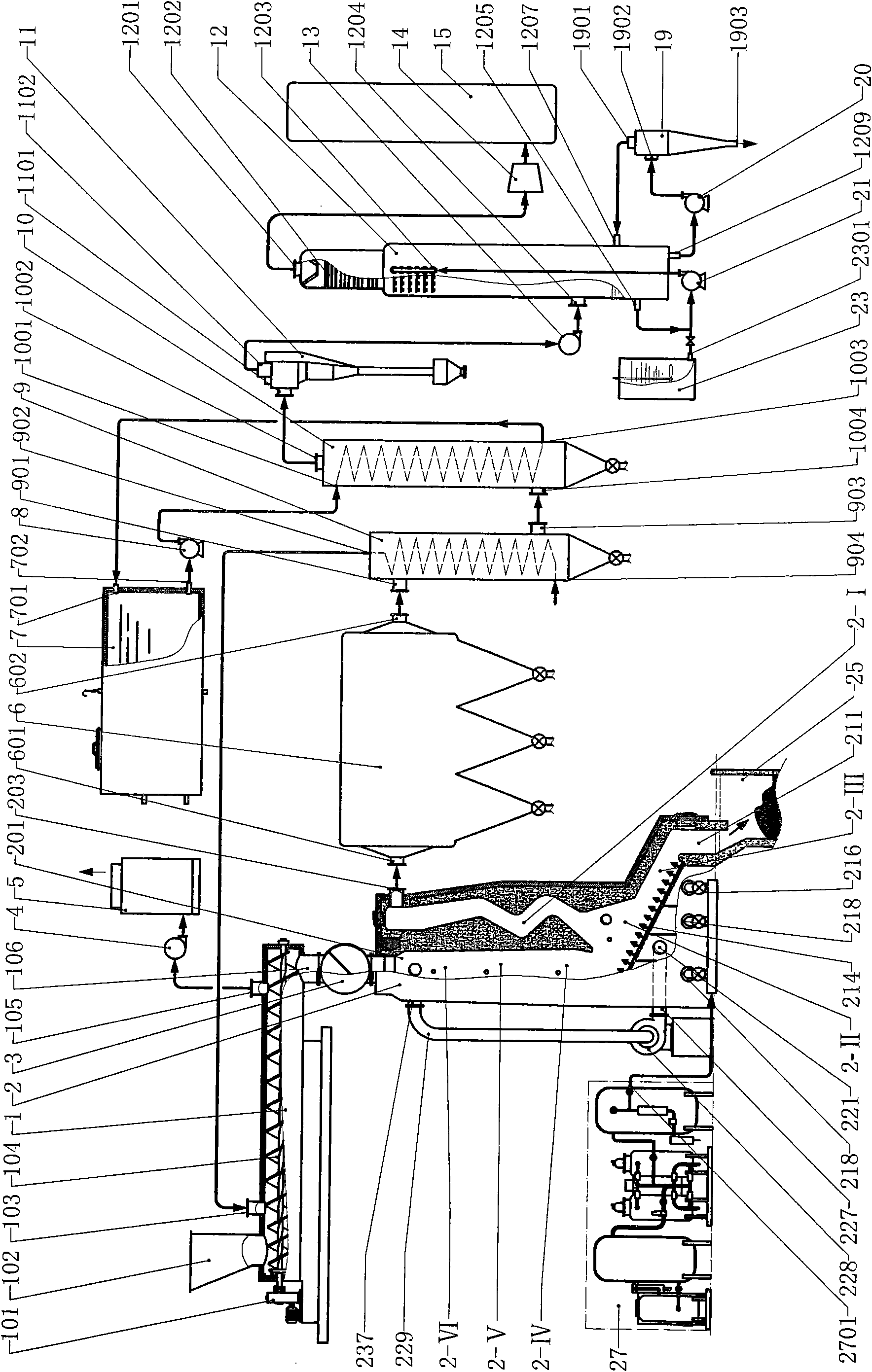

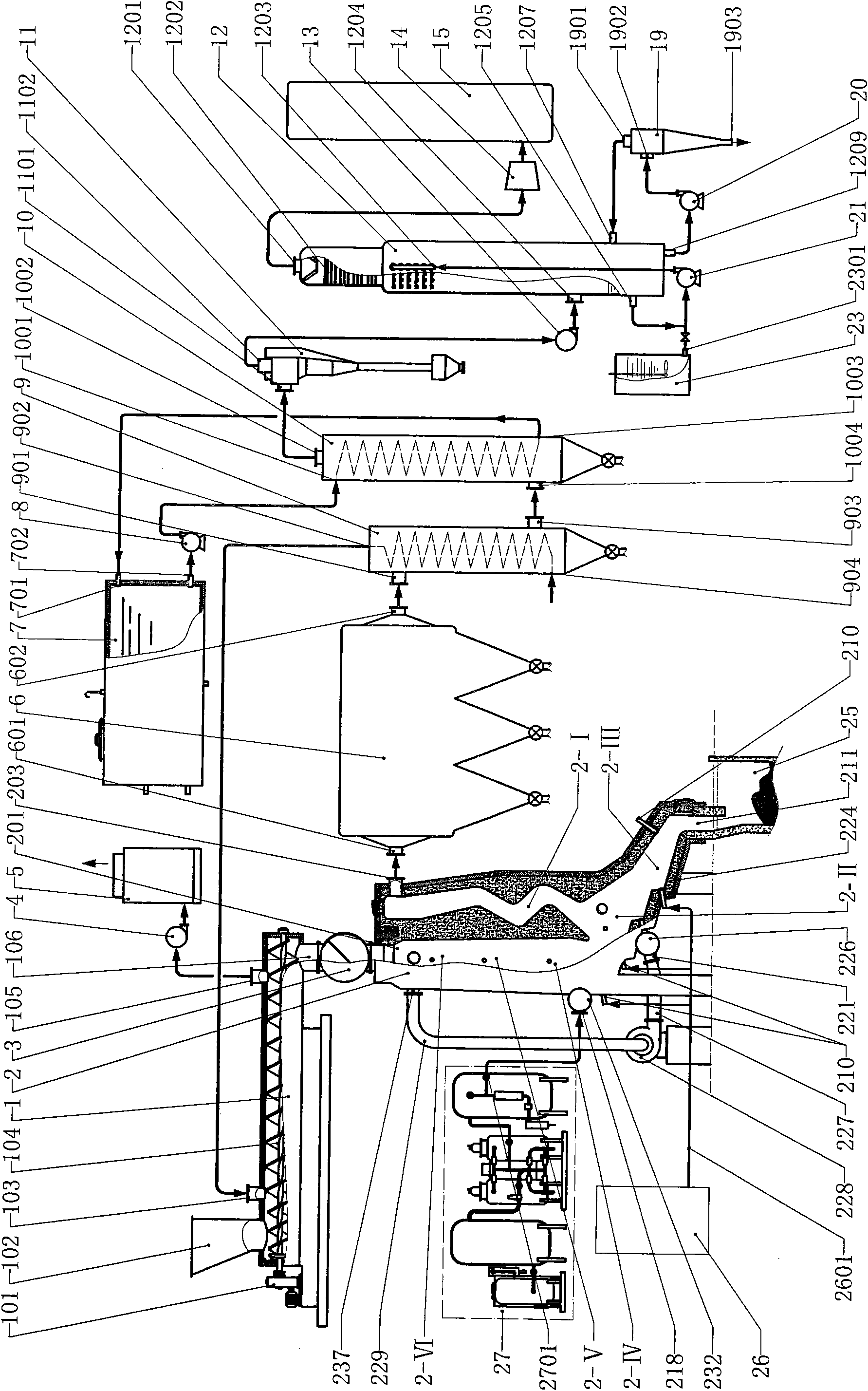

[0041] figure 1In the shown embodiment, the gasification system for processing domestic waste is mainly composed of an air dryer (1), an isolation valve (3), a gasification furnace (2), a waste heat boiler (6), an air preheater (9), a quenching Air dryer (10), cyclone dust collector (11), wet purifier (12), compressor (14), gas cabinet (15) and connecting pipelines, wherein: air dryer (1) is a horizontal cylindrical device , an insulation layer is arranged outside the cylinder, a garbage hopper (102) and an air supply port (103) are arranged in sequence at the front of the air dryer (1), an air exhaust port (105) is arranged at the rear, and the discharge port (106) of the air dryer is at the tail , the air dryer (1) is provided with a screw conveyor (104), which is used to transport the garbage material in the air dryer from front to back, and the screw conveyor (104) is driven by a gearbox (101) outside the device; (2) It is a gas phase circulation gasifier, the feed inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com