Clean incineration system of refuse and organic wastes and device thereof

A technology for organic waste and purification equipment, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of low cost, complex flue gas purification system, and high pollutant content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

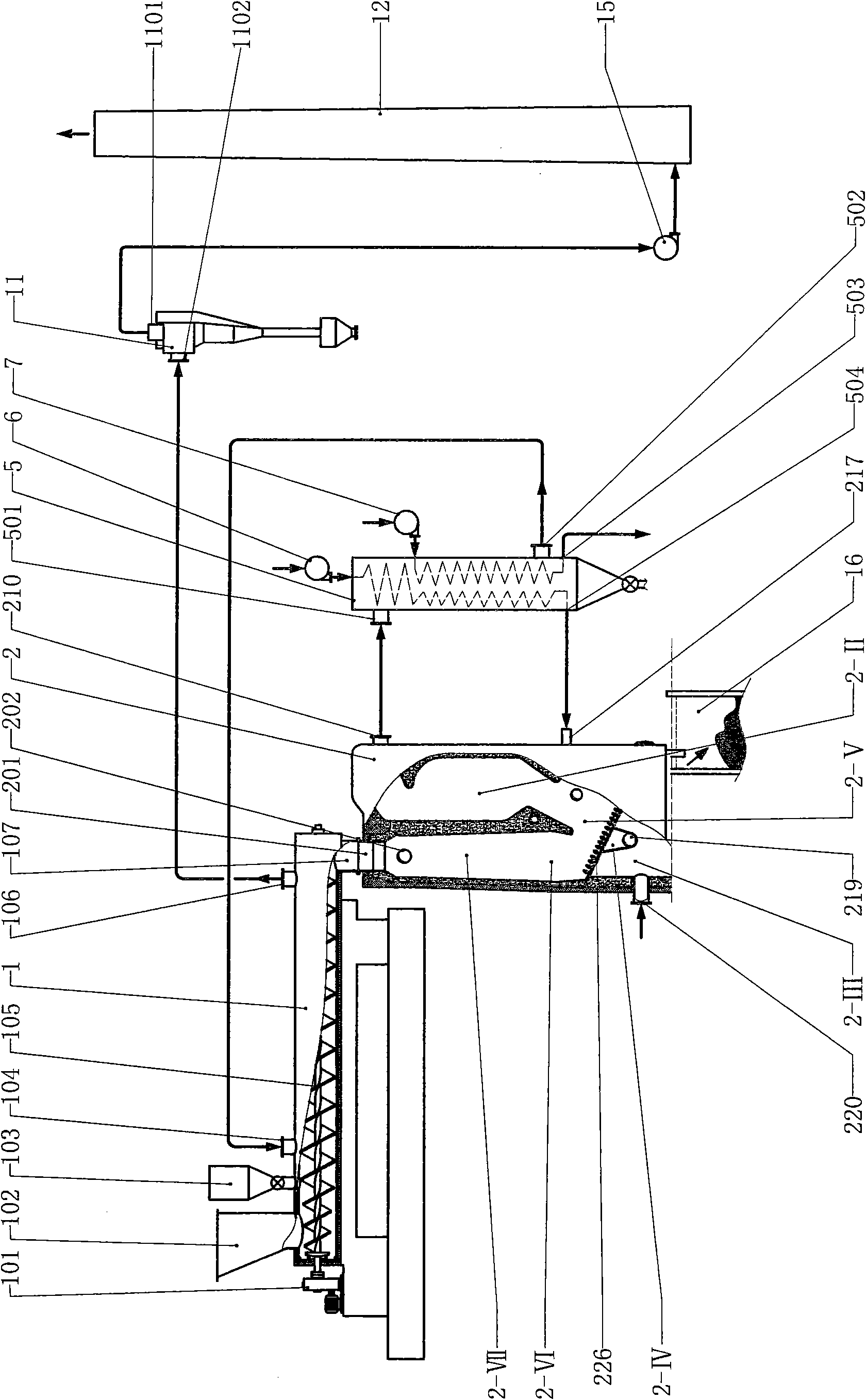

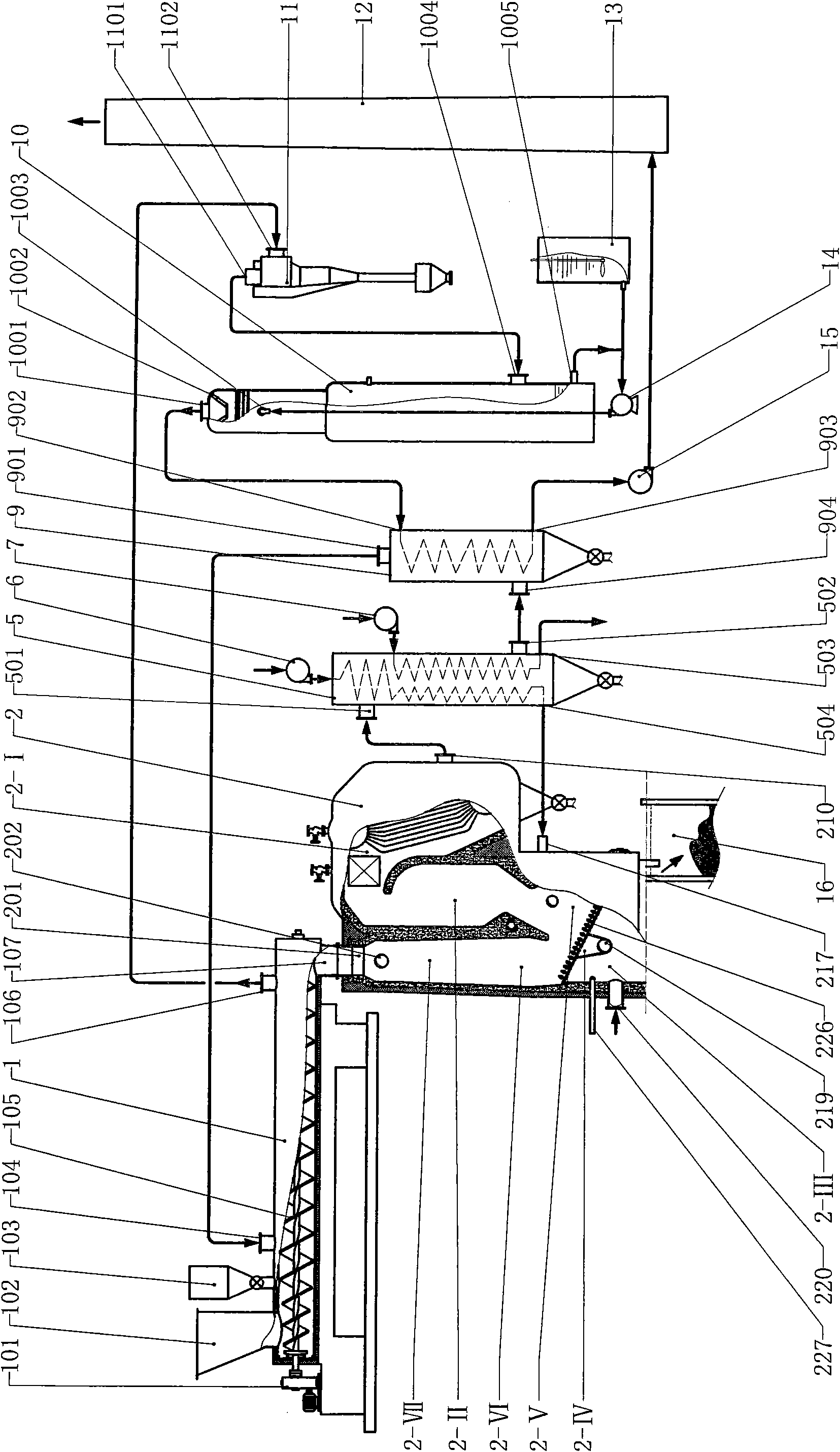

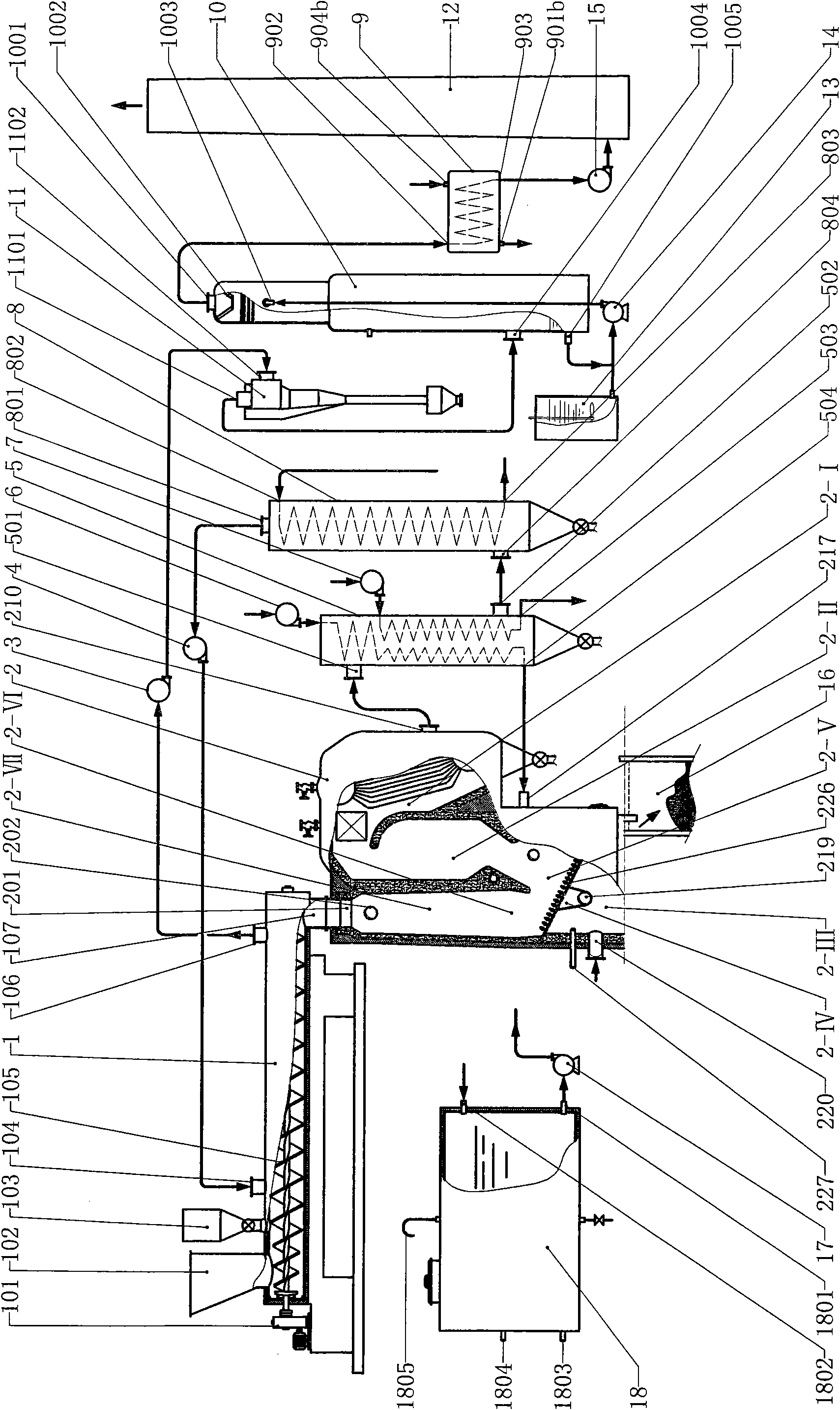

[0031] figure 1 The illustrated embodiment is a system for treating high-moisture domestic waste by clean incineration suitable for small-scale waste incineration plants in villages and towns. The system mainly consists of air dryer (1), incinerator (2), air preheater (5), It consists of cyclone dust collector (11), induced draft fan (15), chimney (12) and connecting pipes, wherein: the air dryer (1) is a horizontal cylindrical device, and an insulation layer is arranged outside the cylinder, and the front of the air dryer (1) Garbage hoppers (102), additive hoppers (103) and air outlets (104) are arranged in sequence at the front, air exhaust outlets (106) are arranged at the rear, and the discharge port (107) of the air dryer is at the tail. The screw conveyor (105) is used to convey the garbage material in the air dryer from front to back, and the screw conveyor (105) is driven by the gearbox (101) outside the device; the incinerator (2) is a gas phase circulation incinerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com