Clean incineration system of refuse and organic wastes and device thereof

A technology for organic waste and purification equipment, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of ineffective elimination of carcinogenic and highly toxic dioxins, waste of resources, and high pollutant content

Inactive Publication Date: 2011-01-05

周开根

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, China's domestic waste treatment mainly includes sanitary landfill technology, composting (biochemical) technology and incineration technology. Most areas use sanitary landfill method to deal with domestic waste, which not only takes up a lot of land, wastes resources, but also easily pollutes land and groundwater; composting only utilizes about 40% of organic matter, and it is necessary to build supporting incineration process equipment and sanitary landfills. Heavy metals in composting products may pollute the soil and enter the food chain crops, and there are also secondary Hidden dangers of secondary pollution; the incineration method is used to deal with urban domestic waste, and the waste heat is used for power generation or heat supply, which can reduce the amount and recycle domestic waste. However, due to the high water content and low calorific value of domestic waste, ordinary garbage The incineration equipment needs to use conventional fuels such as coal or fuel oil to support combustion during operation. At the same time, there are disadvantages such as high pollutant content in the flue gas, inability to effectively eliminate carcinogenic and highly toxic dioxins and furans, and complex flue gas purification systems; the existing Garbage incineration equipment is only suitable for processing urban domestic waste, but cannot be popularized in villages and towns. It cannot realize low-cost and meet environmental protection requirements for processing village and township domestic waste with higher moisture content and lower calorific value.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

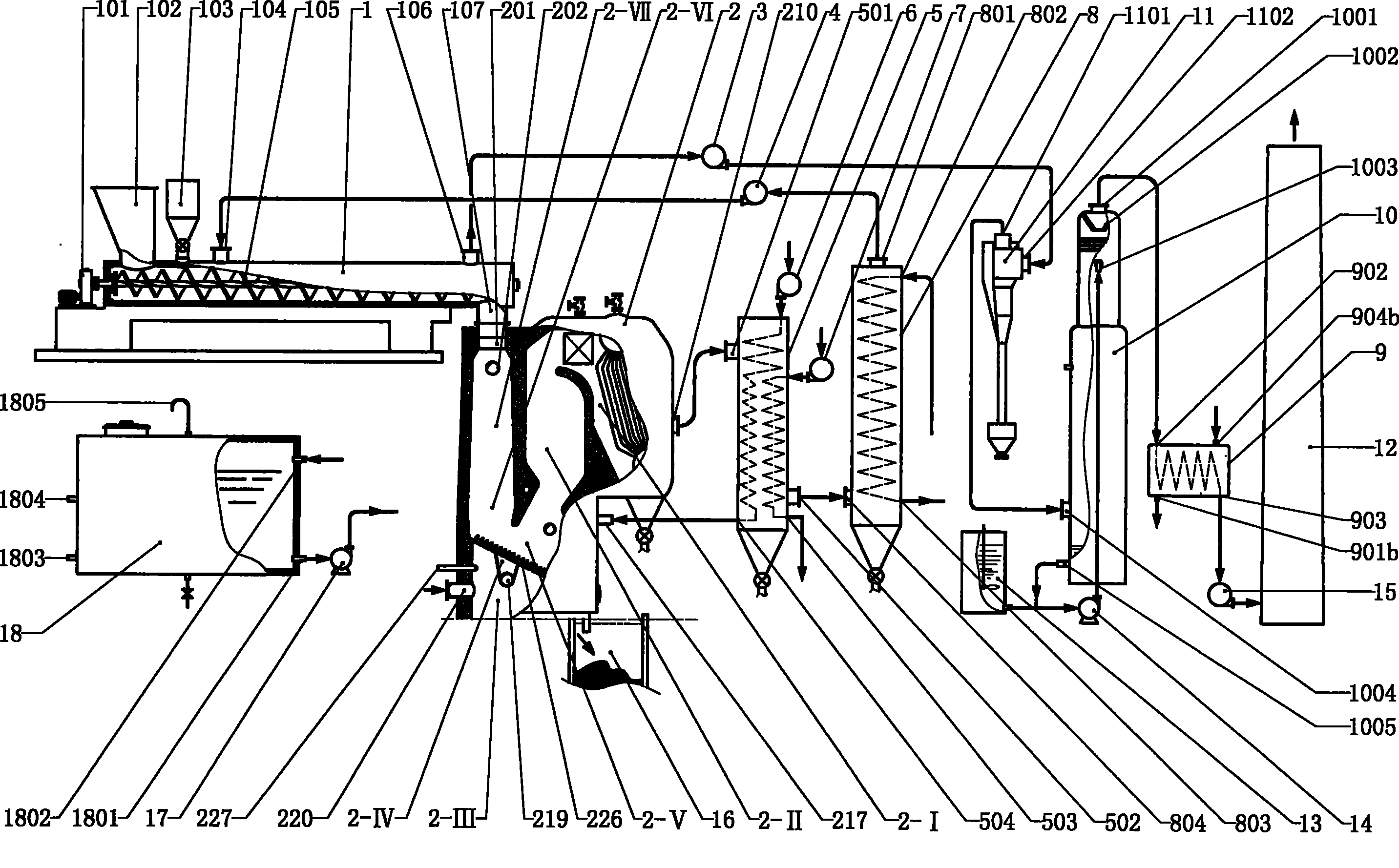

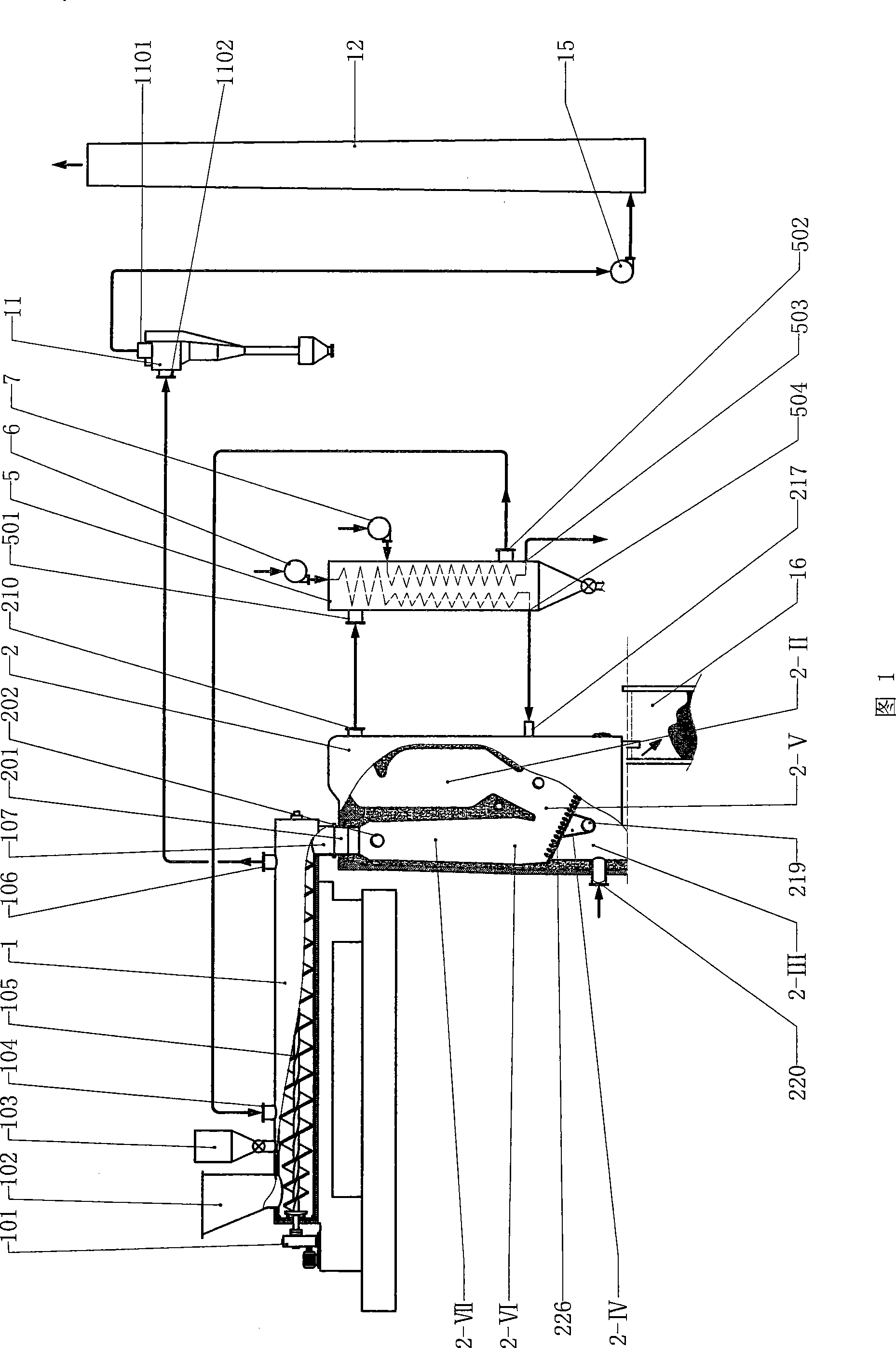

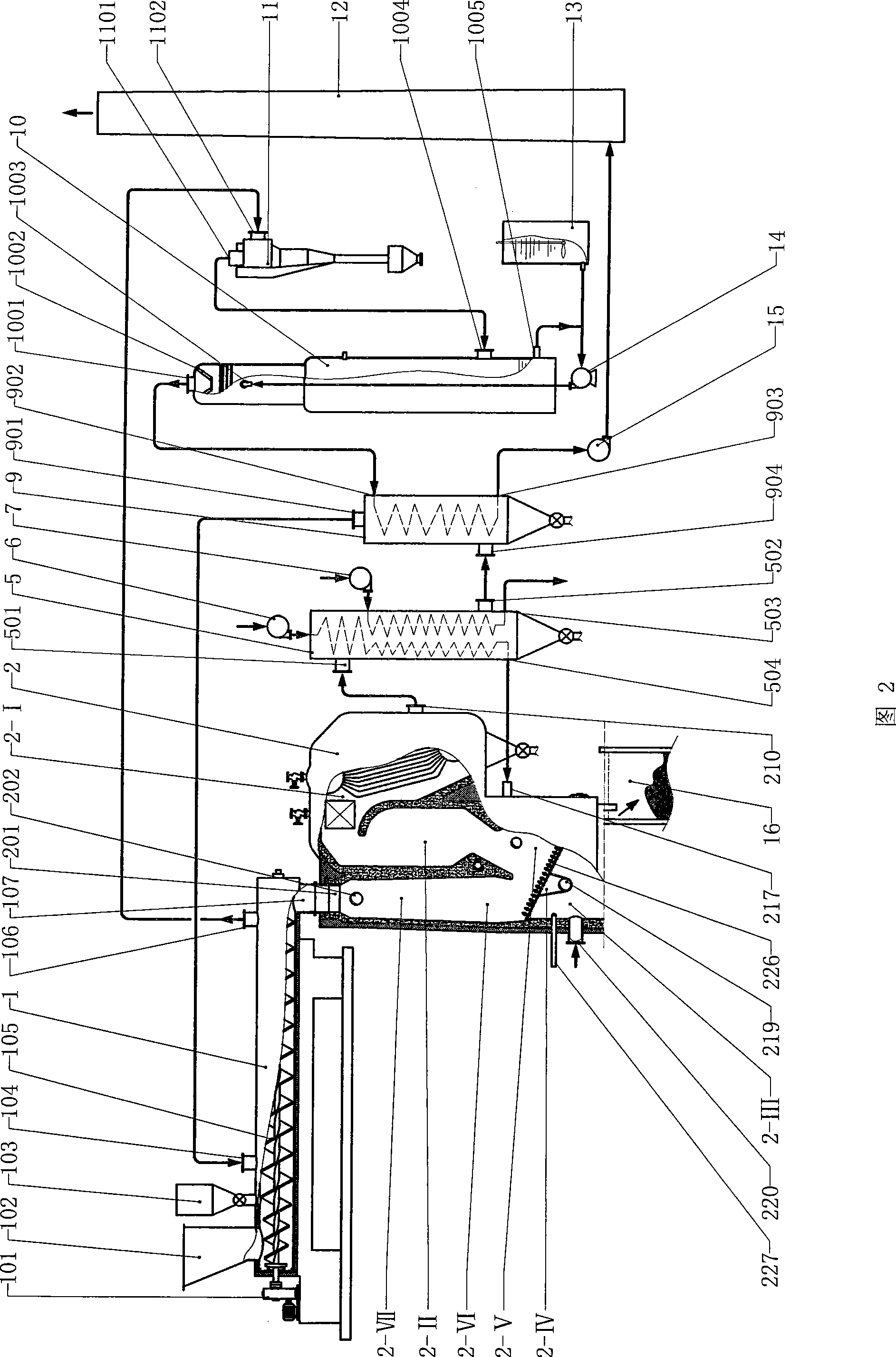

A clean incineration system of refuse and organic wastes and a device thereof relate to refuse incineration equipment. The incineration system mainly consists of an dry fan, a gas phase circulating incinerator, an air preheater, a dedusting / purification device, an induced draft fan and a chimney, a discharge outlet of the dry fan is connected to a feed inlet of the incinerator, a fume outlet of the incinerator is connected to the air preheater, the air preheater is connected to an air supply outlet of the dry fan, a suction opening of the dry fan is connected to a fume inlet of the dedusting / purification device, and a fume outlet of the dedusting / purification device is connected to the chimney by the induced draft fan. A dry distillation zone and a gasification zone form a gasification environment, and a first combustion zone and a second combustion zone form a combustion environment in the gas phase circulating incinerator, and a circulating air conduit and a circulating fan form a gas phase circulation loop outside the incinerator. Refuse fuel is gasified in the incinerator for combustion, and gaseous material generated in the gasification environment is allowed to have circulating gasification and combustion. The system and the device have the advantages of high burnout ratio, few pollutants generated from combustion and clean incineration of refuse.

Description

System and equipment for clean incineration of garbage and organic waste Technical field The invention relates to garbage and organic waste treatment equipment, in particular to garbage incineration equipment. Background technique At present, the energy shortage and the environmental protection situation are grim. With the development of my country's national economy and the continuous expansion of urban scale, garbage is increasing rapidly, and its content of harmful components is getting higher and higher. If it is not handled properly, it will pollute the environment and threaten people's health. This will not only restrict The progress of the society also affects the sustainable development of the national economy. At present, China's domestic waste treatment mainly includes sanitary landfill technology, composting (biochemical) technology and incineration technology. Most areas use sanitary landfill method to deal with domestic waste, which not only takes up a lot of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F23G5/04F23G5/46F23G5/44F23J15/00F23L15/00F23G5/027

CPCY02E20/34

Inventor 周开根

Owner 周开根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com