Waste storage tank for dehydrating waste

A technology of garbage dehydration and garbage pool, applied in the direction of solid waste removal, etc., can solve the problems of low processing efficiency, high construction cost, gas leakage, etc., and achieve the goals of reducing investment and operating costs, small volume, and increasing low-level calorific value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

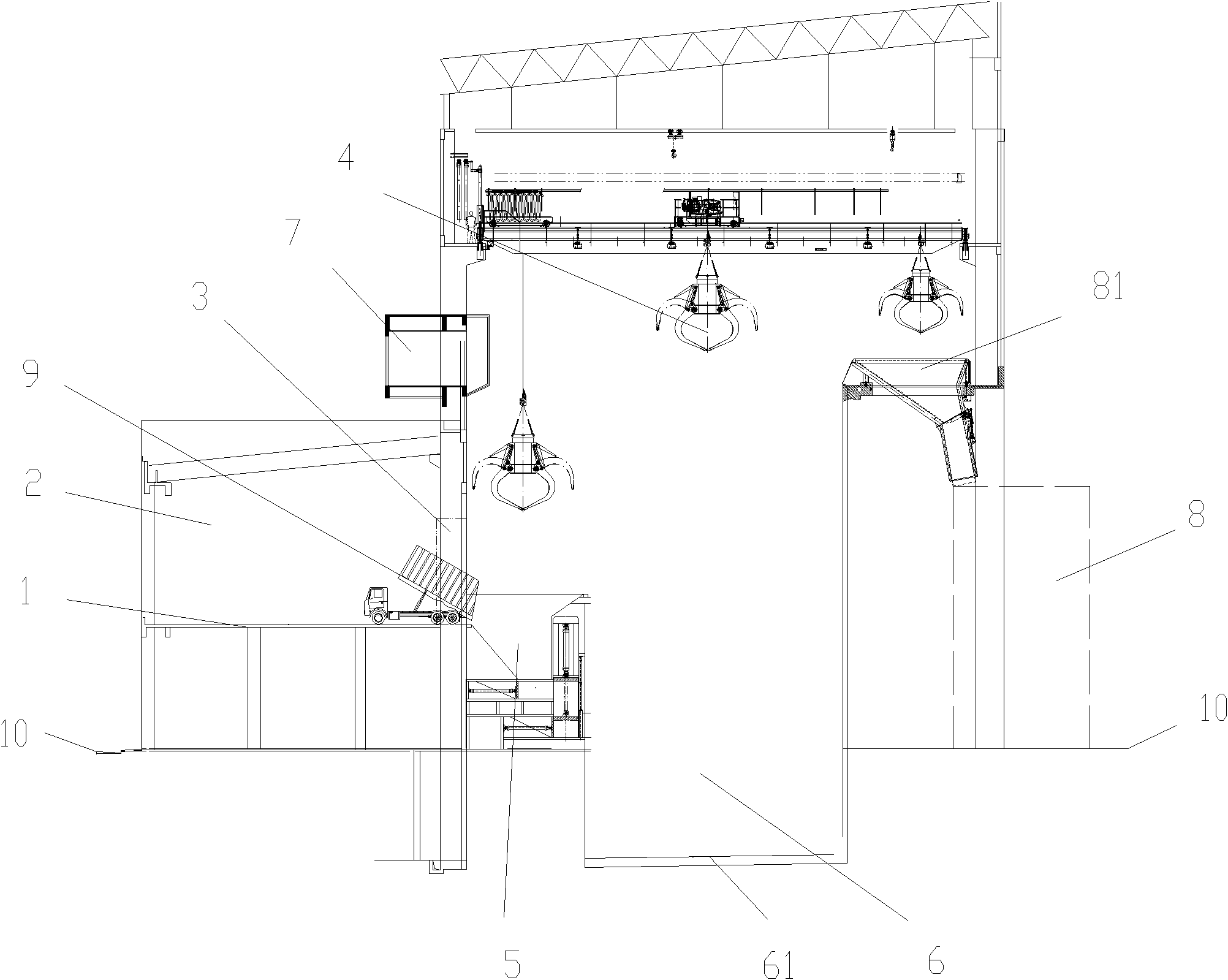

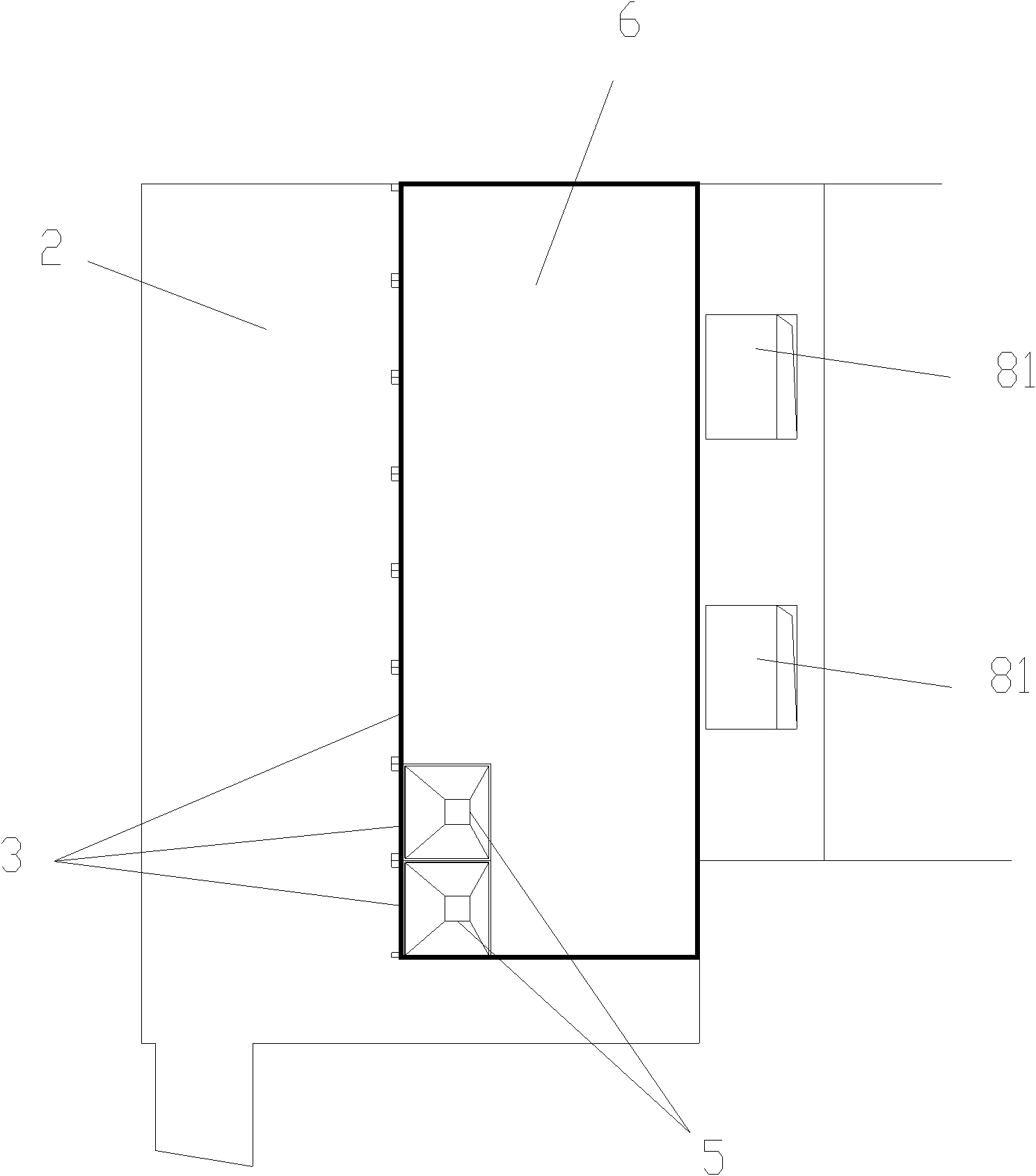

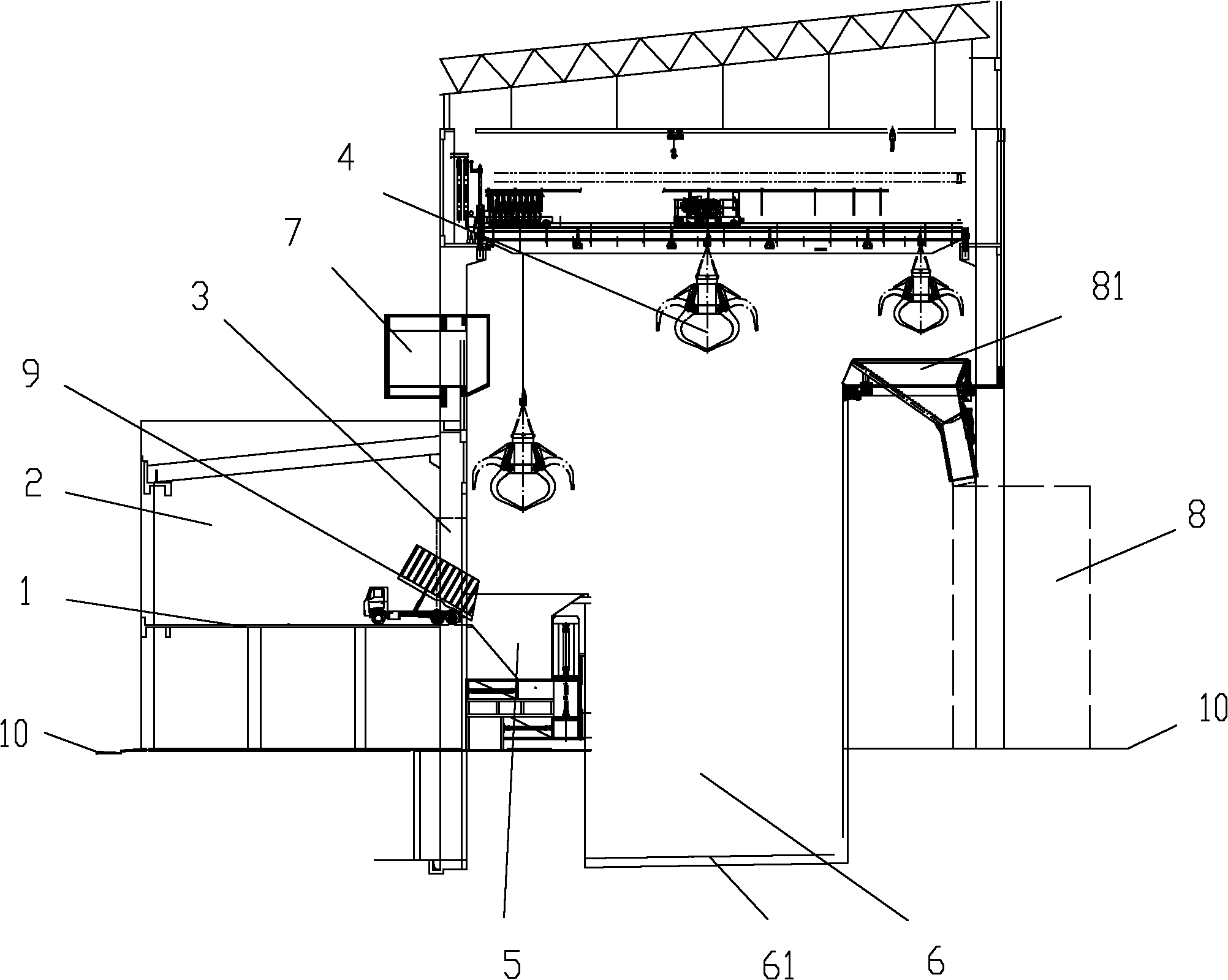

[0018] Please refer to figure 1 and figure 2 , the present embodiment is used for realizing the garbage pond of dehydration processing and comprises garbage pond body 6, is arranged on the discharge door 3 of garbage pond body 6 side, is arranged on the overhead crane and the garbage grab bucket 4 below the garbage pond roof and is contained in The compression type garbage dehydrator 5 below the discharge door 3.

[0019] The compressed garbage dehydrator 5 has a receiving hopper with an upward opening. The receiving hopper is located below the discharge door 3 , and a discharge platform 1 and a discharge hall 2 are arranged outside the discharge door 3 . Specifically, a plurality of discharge doors 3 are arranged on the side wall of the garbage pool on the side of the discharge hall 2, and these discharge doors 3 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com