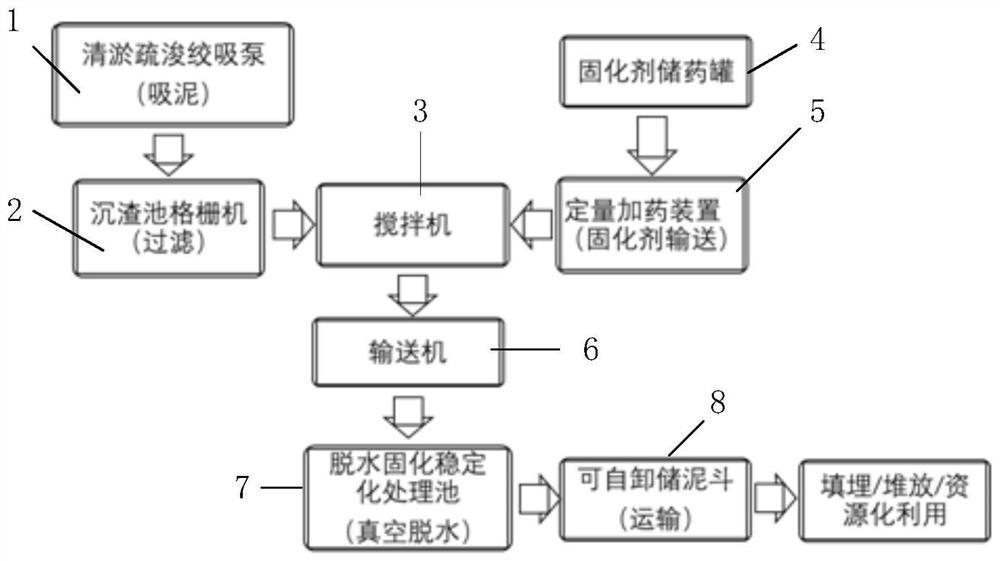

An integrated method and equipment for rapid dehydration, solidification and stabilization of dredged polluted sediment

A technology of polluted sediment and rapid dewatering, applied in chemical instruments and methods, water/sludge/sewage treatment, polluted waterway/lake/pond/river treatment, etc. It can improve the efficiency of dehydration treatment, save sites and costs, and reduce pollutant emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

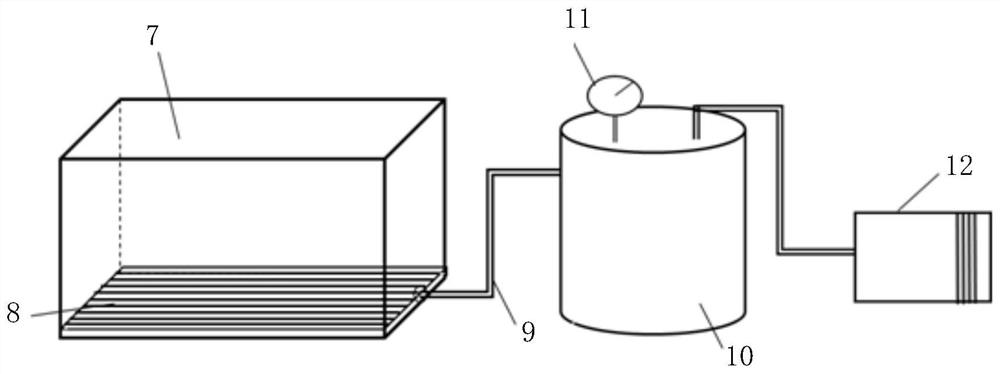

Method used

Image

Examples

specific Embodiment 1

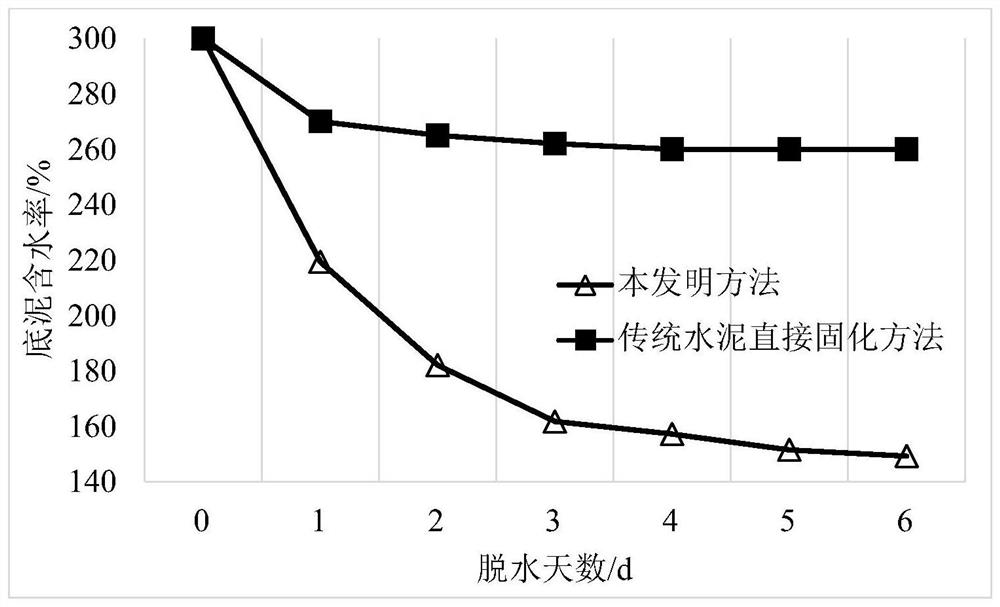

[0042] The dredged bottom mud used in this embodiment is the South Lake bottom mud in Wuhan. According to the initial moisture content of the dredged bottom mud and the concentration value of the initial pollution heavy metal zinc, the moisture content is adjusted to 300% in this embodiment, and the concentration value of the heavy metal zinc pollution is 800mg / kg, so that the treatment objects of the experimental group and the control group are consistent, and it is convenient to directly compare the difference in treatment effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com