Riverway sludge dredging system

A technology for river silt and silt, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of surrounding environmental impact, long-term exposure of silt, and foul odor of silt, etc. , to achieve the effect of reducing the diffusion of odor, facilitating filter press dehydration treatment, and reducing the impact on the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

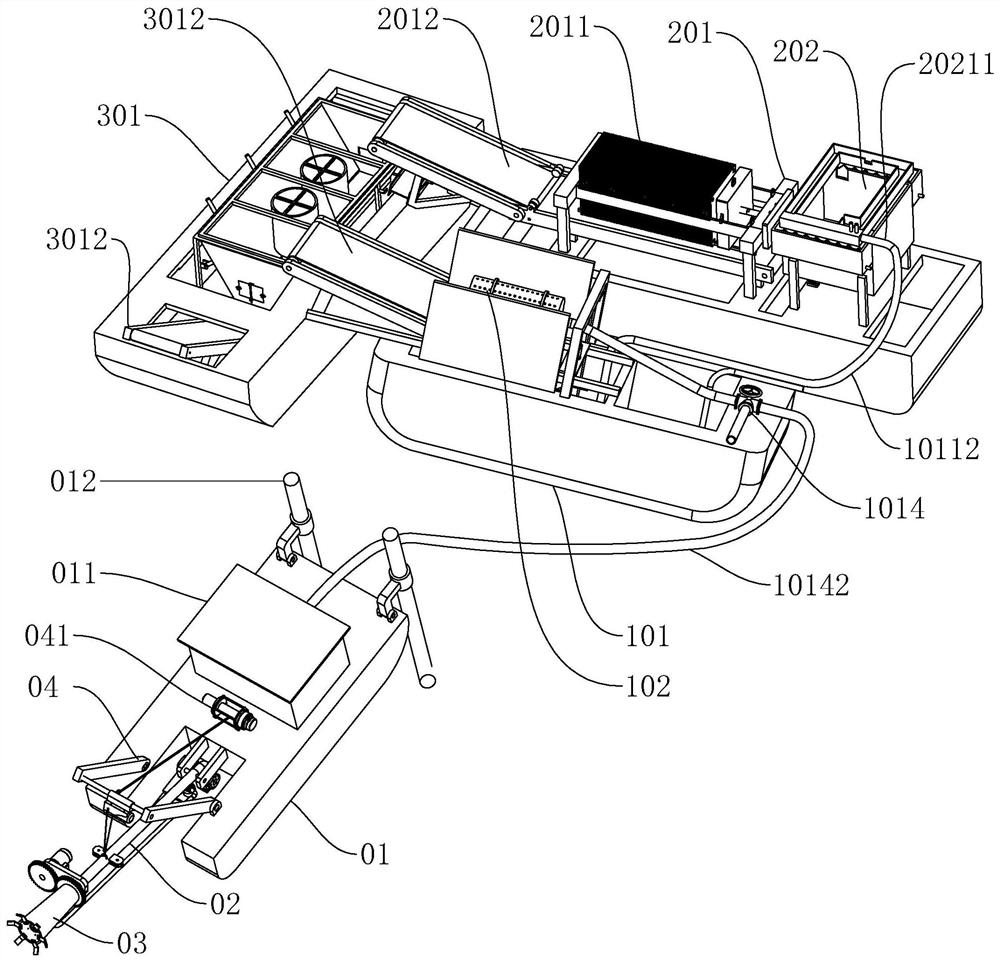

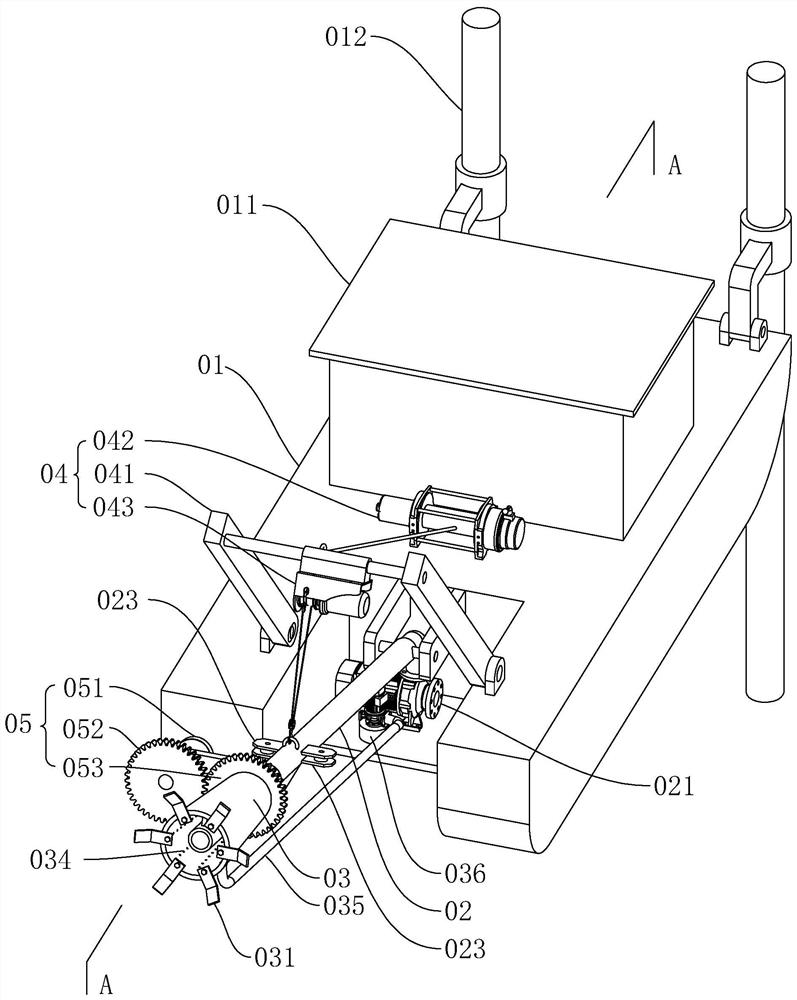

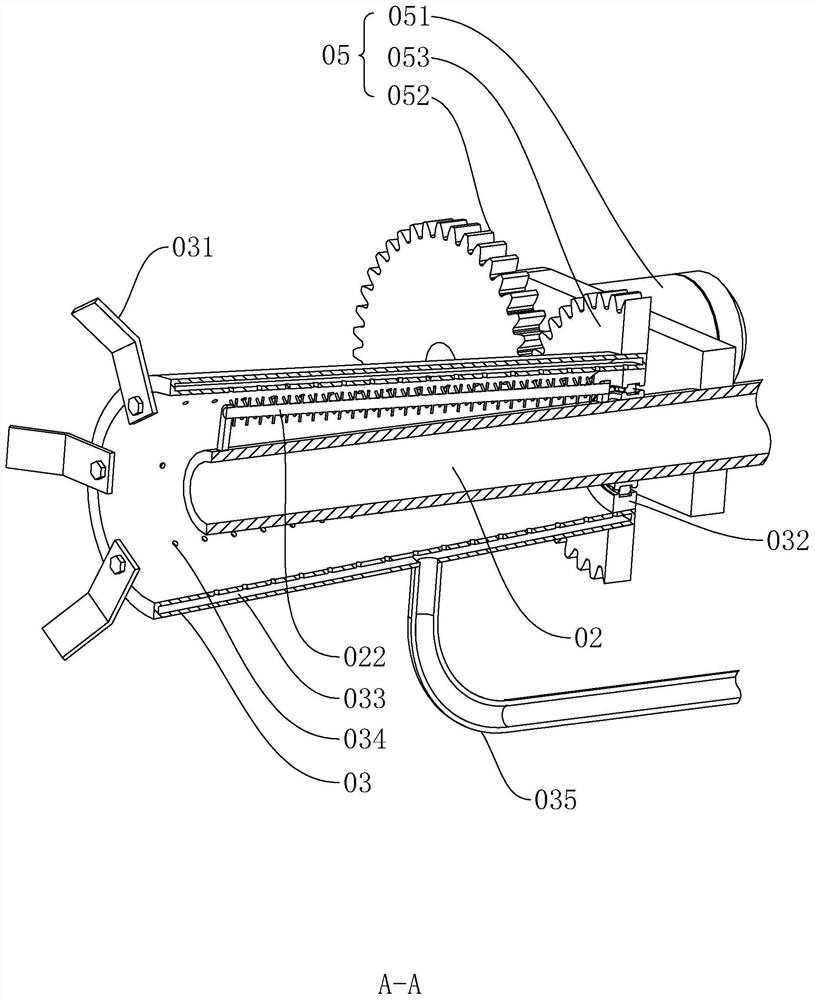

[0040] The following is attached Figure 1-10 The application is described in further detail.

[0041] The embodiment of this application discloses a river channel silt dredging system, such as figure 1 As shown, it includes a suction dredger 01 for sucking out the silt at the bottom of the river, a dewatering ship 201 for pressing and dehydrating the sludge, and a collection ship 301 for storing dehydrated sludge blocks. The suction dredger 01 and the dewatering ship There is an impurity removal ship 101 between 201, and a screening device 102 for separating solid impurities from fluid sludge is installed on the impurity removal ship 101.

[0042] During dredging operations, the dredger 01 can suck out the silt at the bottom of the river into the storage bin 011 and transport it to the impurity removal ship 101 through the silt inlet pipe 10142 .

[0043] The screening equipment 102 on the impurity removal ship 101 can screen the silt sucked from the river, so as to separate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com