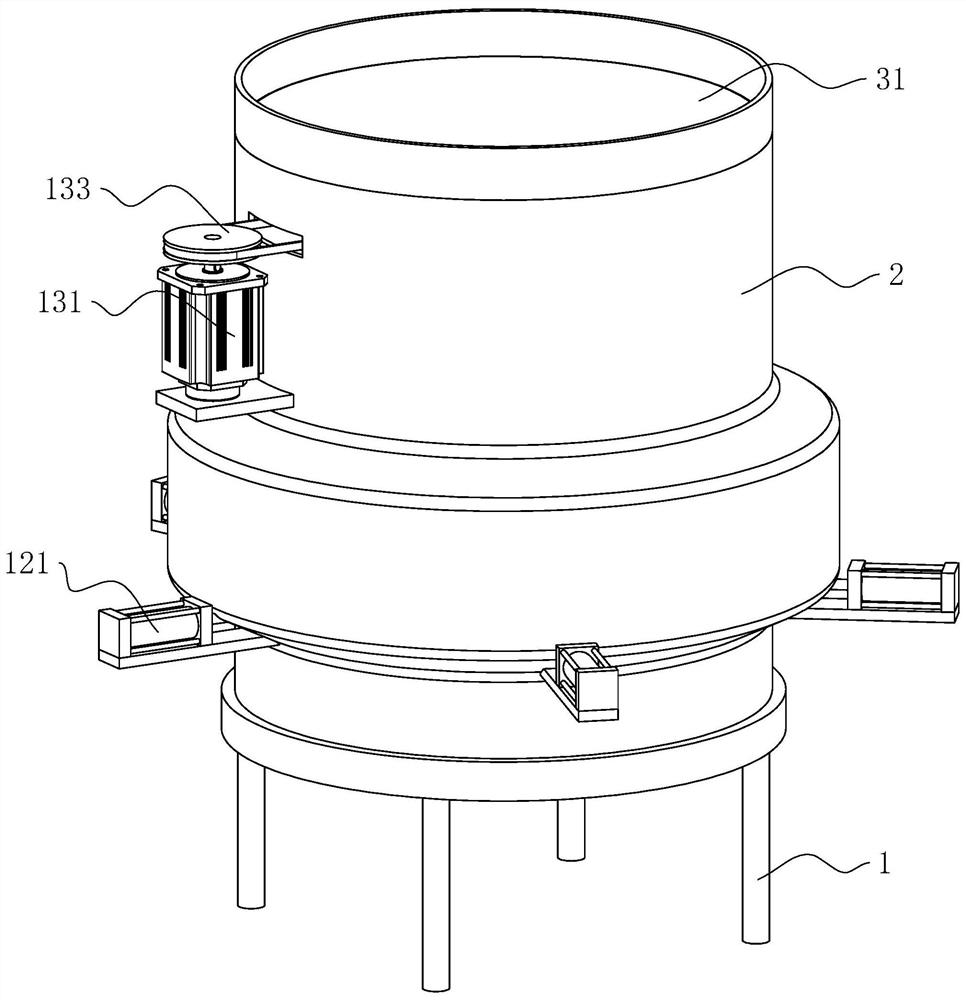

Sludge treatment device and method

A sludge treatment and sludge technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Multi-energy and other issues, to achieve the effect of saving energy, improving efficiency, and speeding up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

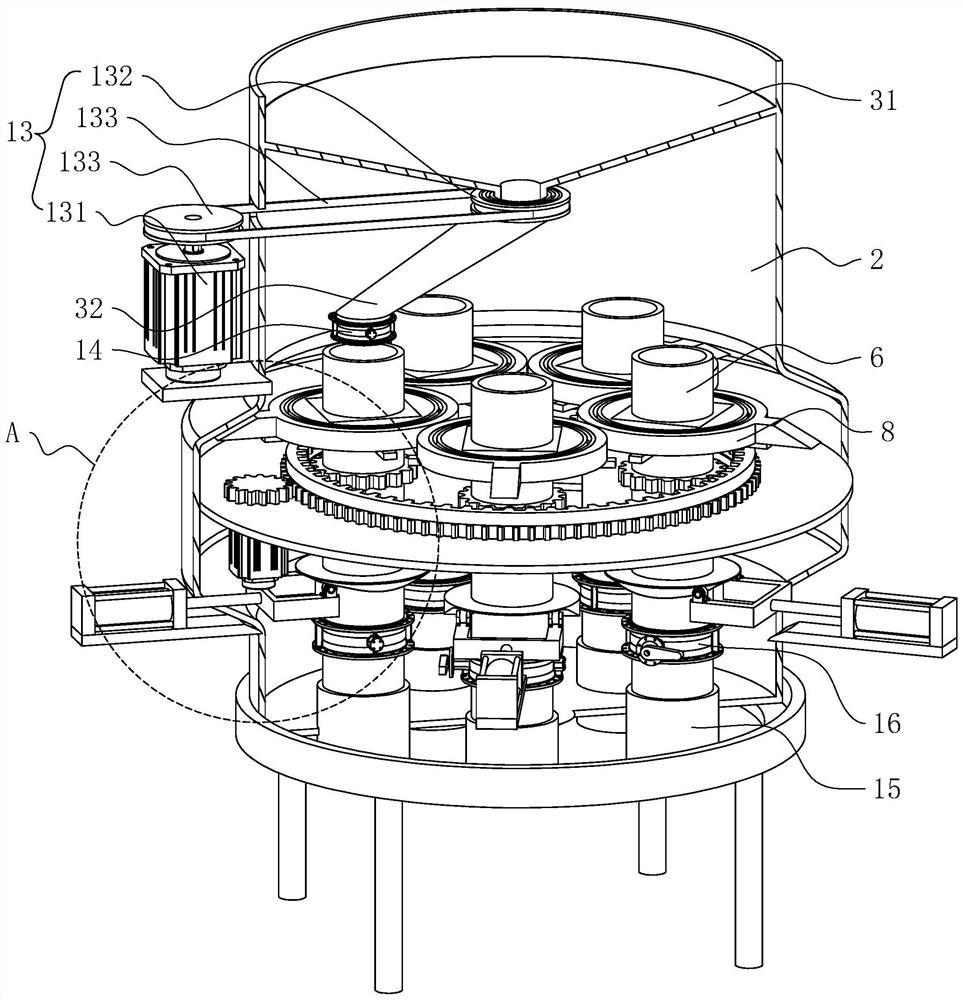

Embodiment 1

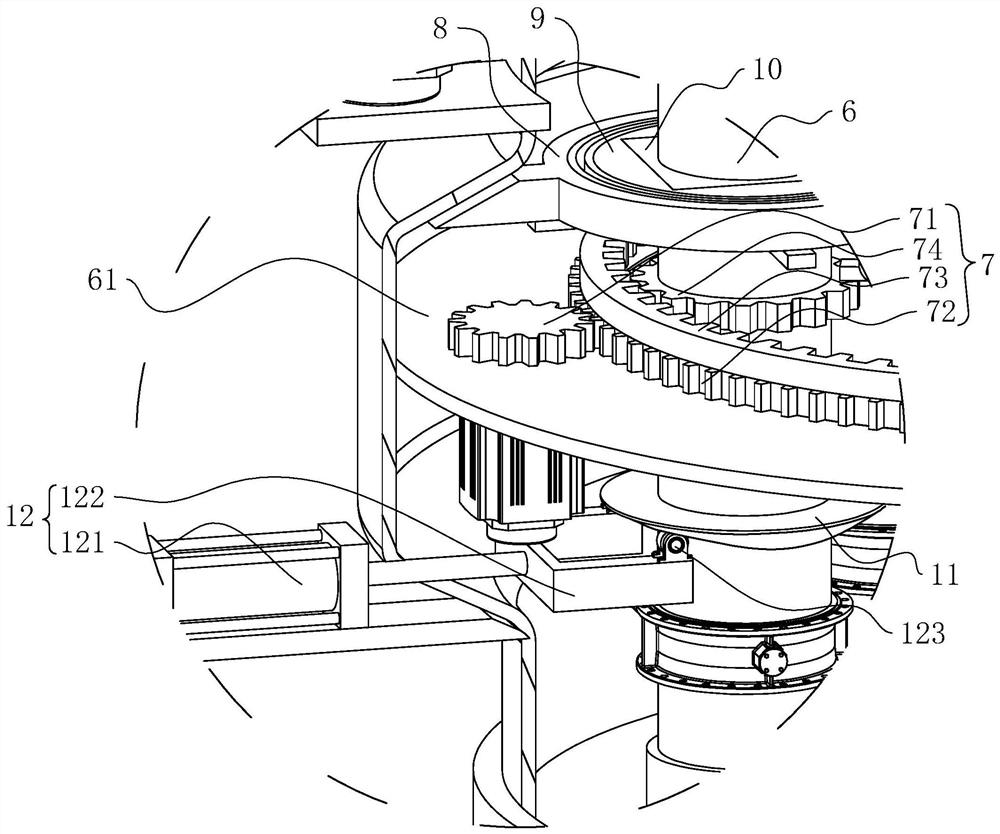

[0049] The implementation principle of Embodiment 1 is: when treating sludge, transport the sludge to the feed hopper 31 at the upper end of the machine body 2, the sludge in the feed hopper 31 will enter the distribution pipe 32, and start the drive motor 131, the driving motor 131 drives the first pulley 132 to rotate, and the first pulley 132 drives the second pulley 133 to rotate through the belt 134, and can drive the distribution pipe 32 to rotate when the second pulley 133 rotates, and the distribution pipe 32 The second vertical part in will rotate directly above a plurality of centrifugal dehydration drums 6 . The material distribution pipe 32 stops above the single centrifugal dewatering cylinder 6, and the first valve 14 is opened, and the material distribution pipe 32 transports the sludge into the single centrifugal dehydration cylinder 6 to realize the sludge feeding.

[0050] Start the servo motor, the servo motor drives the driving gear 71 to rotate, the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com