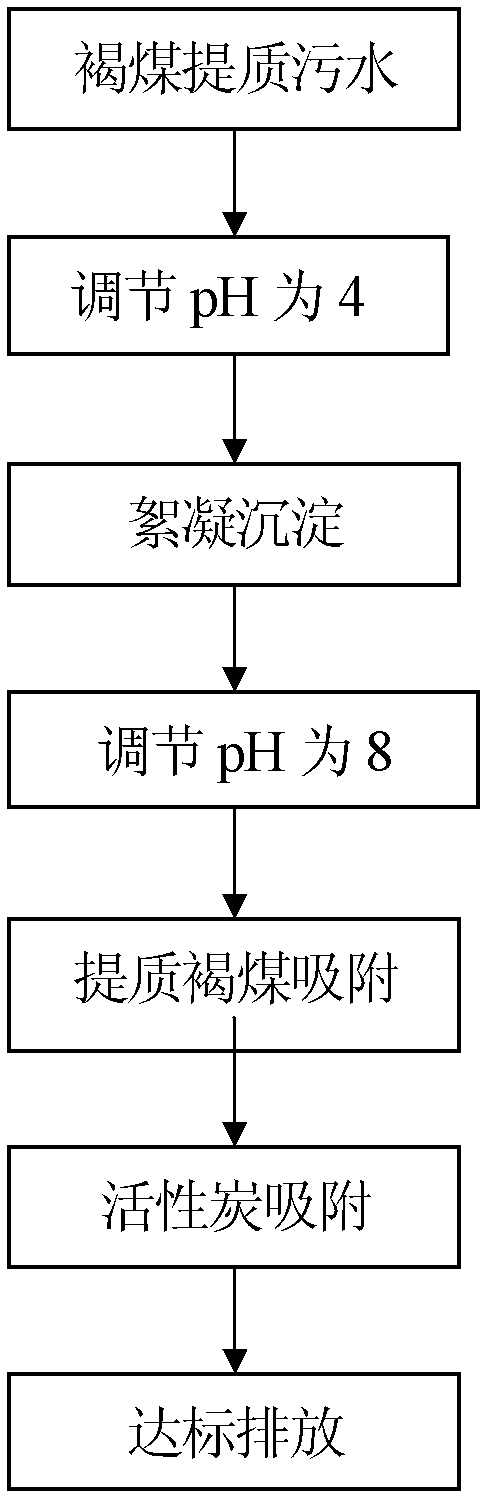

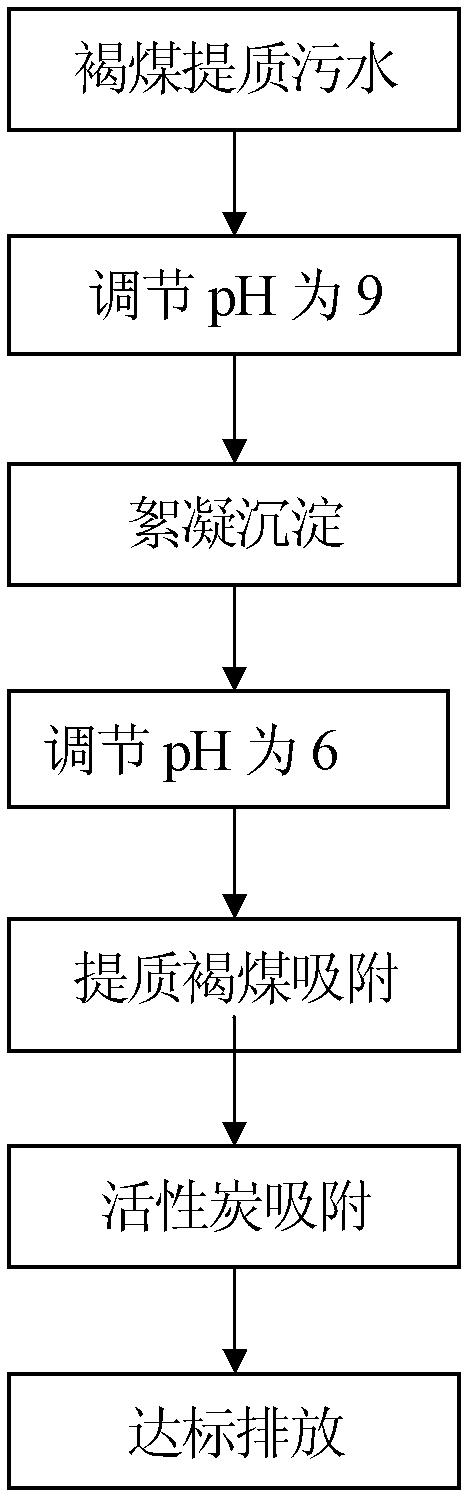

Treatment process of lignite upgrading wastewater

A treatment process and technology for sewage, applied in water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. Achieving the effect of avoiding secondary pollution problems, improving precipitation effect and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 1

[0153] A. take by weighing anionic polyacrylamide (molecular weight 10,000,000) and be mixed with 0.1% solution, quicklime is made into 10% lime solution;

[0154] B. Take 3L Ximeng lignite upgrading sewage, stir and add lime solution, adjust the pH value to 9.5;

[0155] C. Stir and slowly add flocculant aqueous solution, the dosage is 10mg / L;

[0156] D. After stirring for 2 minutes, let it stand for 10 minutes, filter out the sewage with a sieve, and add 98% sulfuric acid to adjust the pH value to 6.5;

[0157] E. Take Ximeng upgraded lignite and add it to the first four water treatment pipes, and add activated carbon HS380 to the last four water treatment pipes. The filling height is 90% (the water treatment pipe is 1m high, the outer diameter of the pipe is 75mm, and the inner diameter 68mm);

[0158] F. Pass the sewage with adjusted pH value through four upgraded lignite water treatment pipes in turn, and then pass through four activated carbon water treatment pipes, a...

test approach 2

[0164] In this test plan, the upgraded lignite was used to adsorb the sewage several times until the color and smell of the effluent did not change significantly, and then activated carbon was used for final treatment to reduce the load of activated carbon as much as possible.

[0165] A. take by weighing anionic polyacrylamide (molecular weight 10,000,000) and be mixed with 0.1% solution, quicklime is made into 10% lime solution;

[0166] B. Take 3L of the sewage produced by upgrading the lignite produced in Ximeng, stir and add lime solution, and adjust the pH value to about 9;

[0167] C. Stir and slowly add flocculant aqueous solution, the dosage is 10mg / L;

[0168] D. After stirring for 2 minutes, let it stand for 10 minutes, filter the sewage with a sieve, and add 98% sulfuric acid to adjust the pH value to 6;

[0169] E. Take the upgraded lignite produced after upgrading the lignite produced in Ximeng, add it to the water treatment pipe, and the filling height is 90% (...

test approach 3

[0177] A. take anionic polyacrylamide (molecular weight 10 million) and be mixed with 0.1% solution, polyaluminum chloride is mixed with 1% solution, quicklime is mixed with 10% solution;

[0178] B. Take 1L lignite upgrading mixed sewage, add different compounds to stir and adjust its pH value;

[0179] C. Stir and slowly add the flocculant aqueous solution, stir for 2 minutes and then observe the test phenomenon.

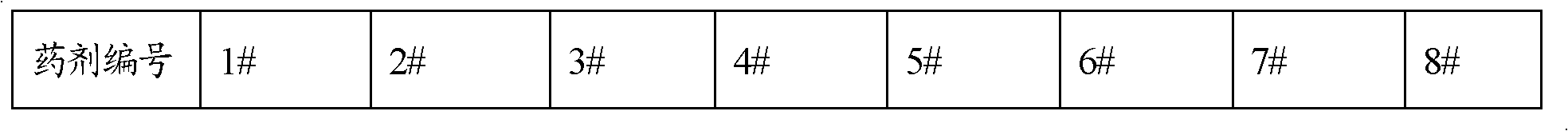

[0180] Table 13 Records of test phenomena

[0181]

[0182] It can be seen from the test phenomenon in Table 13 that the mixed sewage will not agglomerate and precipitate under alkaline conditions. When the pH value is adjusted to 4, the sewage agglomerates and precipitates, and the effect of using polyaluminum chloride (PAC) and polyacrylamide (PAM) as a flocculant is better than using polyacrylamide alone. Wherein the amount of 98% sulfuric acid is 3.2g / L, the amount of PAC is 90mg / L, and the amount of PAM is 6mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com