Sludge drying system

A sludge drying and treatment system technology, applied in the direction of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problem of the reduction of sludge calorific value, the difficulty of leachate phosphorus removal process, and the increase of sludge The difficulty of follow-up disposal and other issues, to achieve the effect of heat recovery and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

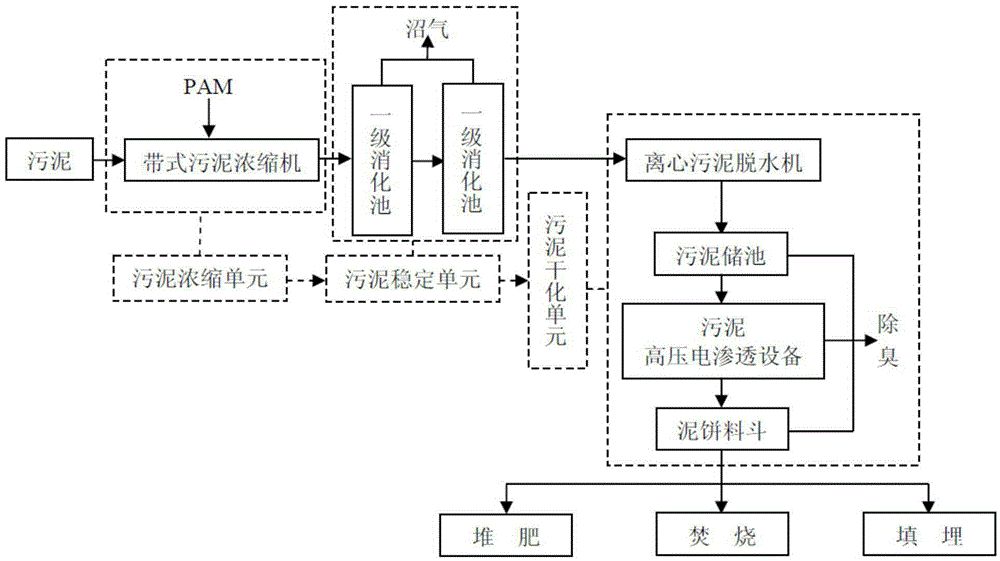

[0013] The sludge drying treatment system of the present invention, its preferred embodiment is:

[0014] Including sludge thickening unit, sludge stabilization unit and sludge drying unit connected in sequence;

[0015] The sludge thickening unit includes a belt sludge thickener, and the belt sludge thickener is provided with a PAM dosing device;

[0016] The sludge stabilization unit is provided with a two-stage anaerobic digester for intermediate temperature sludge, and the anaerobic digester for intermediate temperature sludge is provided with a biogas outlet;

[0017] The sludge drying unit includes a sludge centrifugal dehydrator, a sludge storage tank, a sludge high-voltage electroosmosis equipment, and a mud cake hopper connected in sequence, and the sludge high-voltage electroosmosis equipment is provided with a deodorization device. The mud cake hopper is connected with a composting device, an incineration device and / or a landfill device.

[0018] The sludge high-v...

specific Embodiment

[0027] Such as figure 1 shown, including:

[0028] The sludge treatment system is composed of a sludge thickening unit, a sludge stabilization unit and a sludge drying unit connected in sequence.

[0029] The sludge concentration unit adopts a belt-type sludge thickener. During the concentration process, the dehydration performance of the sludge is improved by adding 1‰ to 5‰ of PAM, and the moisture content of the sludge is concentrated to 92% to 95%;

[0030] The sludge stabilization unit adopts two-stage anaerobic digestion of medium temperature sludge. The temperature is controlled between 34°C and 35°C, and the pH is adjusted by adding NaHCO 3 Control between 7-7.4;

[0031] For the anaerobic digestion of the two-stage medium-temperature sludge, the dosing rates of the primary digester and the secondary digester are controlled at about 5% and 15% respectively, and the digestion days are about 21d and 7d respectively;

[0032] The two-stage anaerobic digestion of mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com