High-temperature high-pressure waste incineration boiler

A waste incineration, high temperature and high pressure technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as high temperature corrosion of superheaters and water cooling systems, achieve the effects of improving thermal efficiency, solving high temperature corrosion, and solving furnace coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

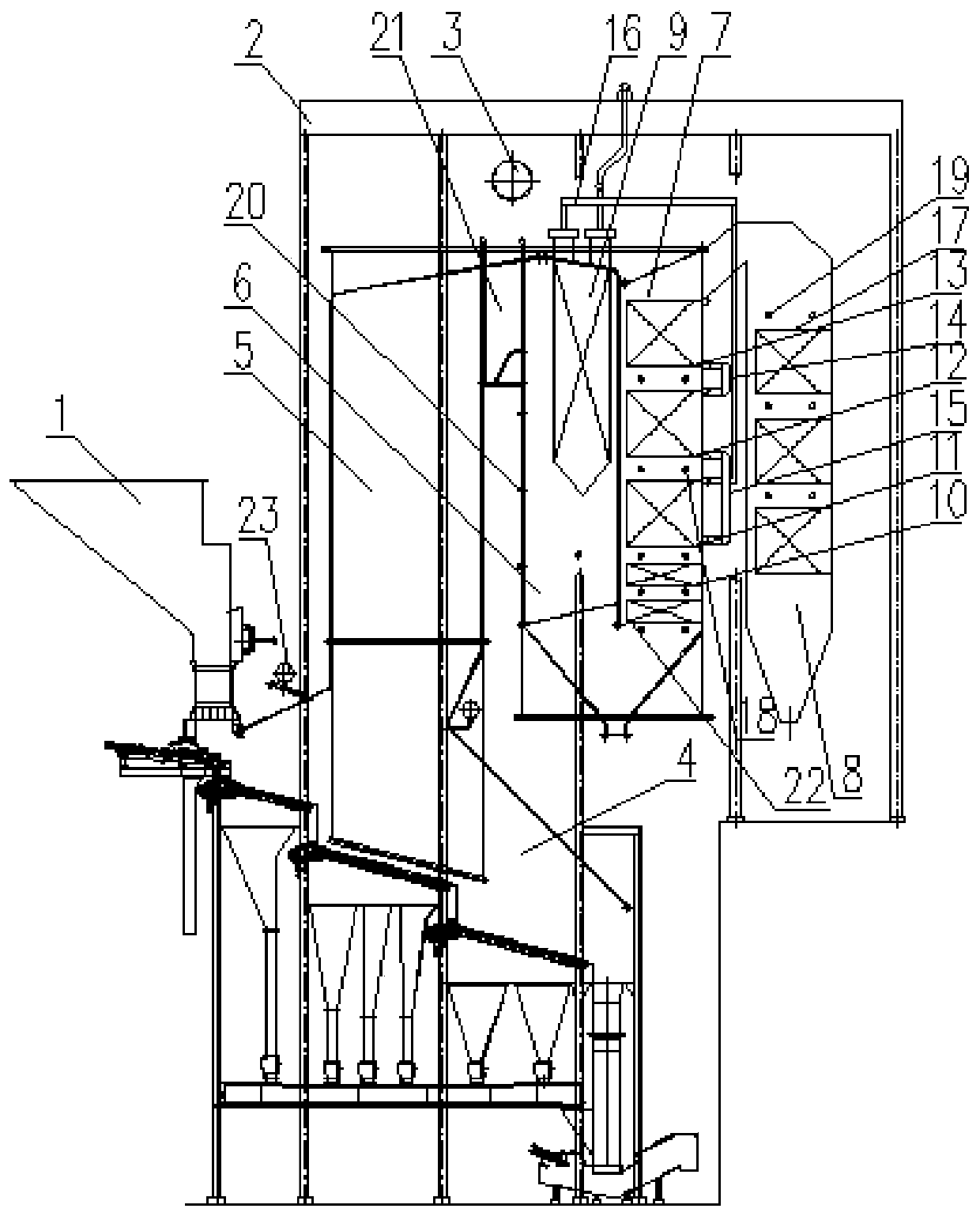

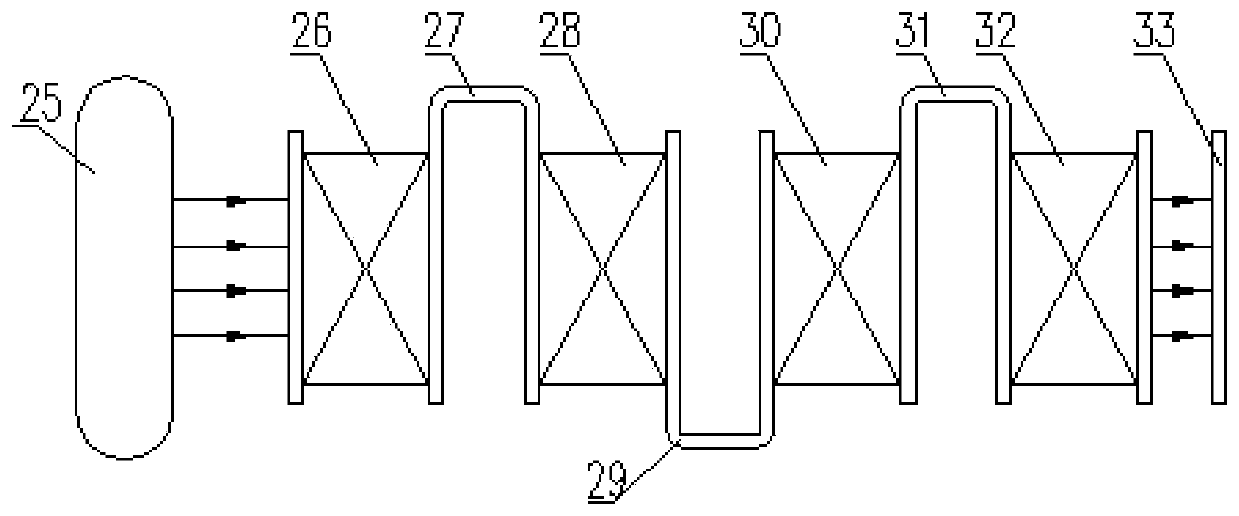

[0031] exist figure 1 In the process, the waste is burned in the incinerator system (1), and the high-temperature flue gas produced enters the waste incineration vertical boiler for waste heat recovery, and high-quality steam is generated and sent to the steam turbine generator set. A high-temperature and high-pressure (9.8MPa, 540°C) waste incineration boiler has a vertical suspension structure. A channel (5), a connecting flue (21) and a second channel ( 6), three-channel (7) and four-channel (8). The water-cooled combustion chamber (4) is composed of a membrane-type water-cooled wall around the grate, refractory bricks are laid in the contact area with the garbage, and high thermal conductivity silicon carbide castables are laid in the rest of the area to reduce the temperature of the combustion chamber to avoid coking. The flue gas recirculation and secondary air nozzles (23) are arranged in the front and rear arch areas of the water-cooled combustion chamber (4). When th...

Embodiment 2

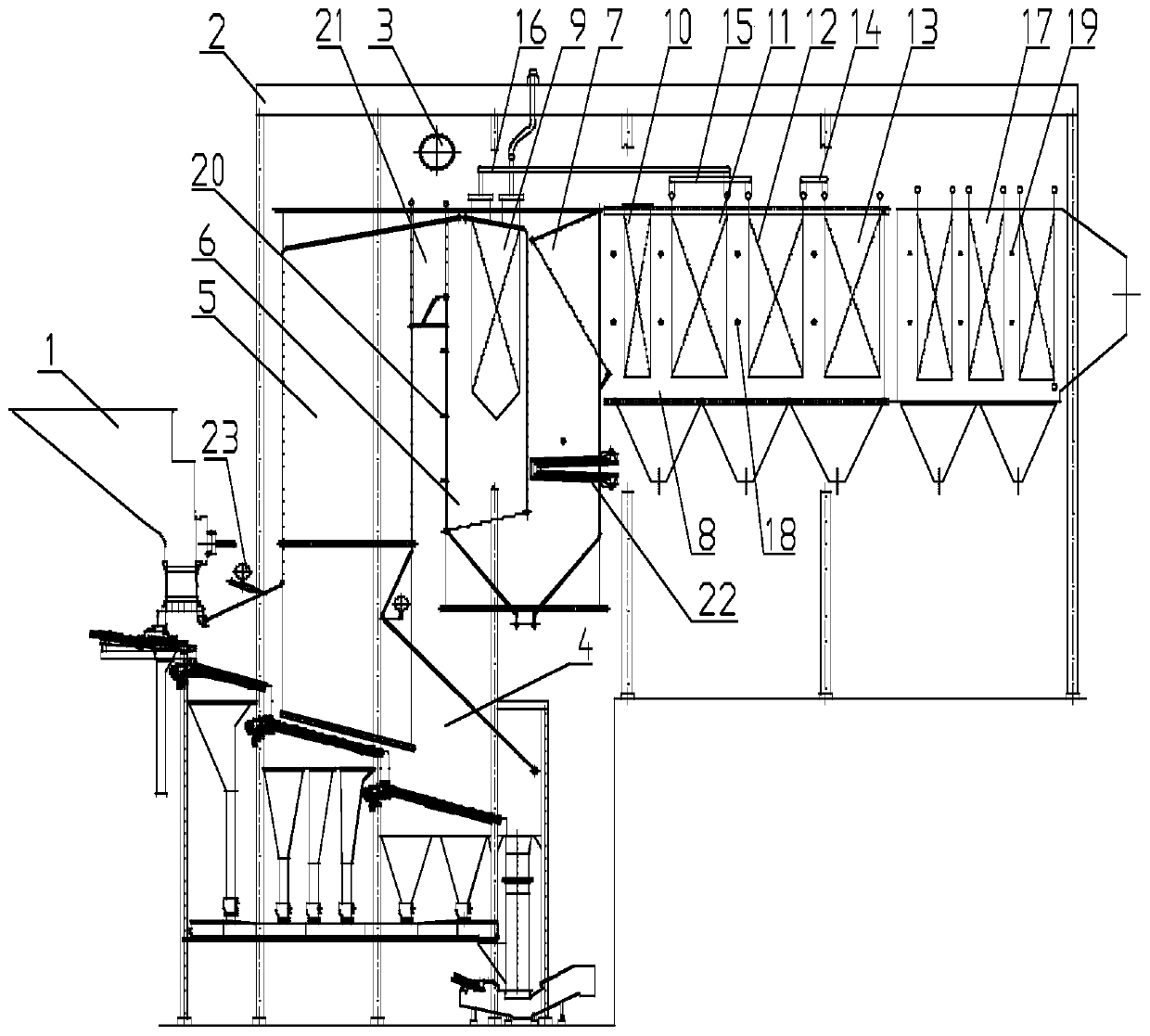

[0034] exist image 3 In the process, the waste is burned in the incinerator system (1), and the high-temperature flue gas produced enters the waste incineration boiler for waste heat recovery, and high-quality steam is generated and sent to the steam turbine generator set. A high-temperature and high-pressure (9.8MPa, 540°C) waste incineration boiler has a horizontal suspension structure. A channel (5), a connecting flue (21) and a second channel ( 6), three channels (7) and horizontal channels (8). The water-cooled combustion chamber (4) is composed of a membrane-type water-cooled wall around the grate, refractory bricks are laid in the contact area with the garbage, and high thermal conductivity silicon carbide castables are laid in the rest of the area to reduce the temperature of the combustion chamber to avoid coking. The flue gas recirculation and secondary air nozzles (23) are arranged in the front and rear arch areas of the water-cooled combustion chamber (4). When t...

Embodiment 3

[0037] exist Figure 5 In the process, the waste is burned in the incinerator system (1), and the high-temperature flue gas produced enters the waste incineration boiler for waste heat recovery, and high-quality steam is generated and sent to the steam turbine generator set. A high-temperature and high-pressure (9.8MPa, 540°C) waste incineration boiler has a π-type suspension structure. A channel (5), a connecting flue (21) and a second channel ( 6), three channels (7), horizontal channels (8) and four channels (24). The water-cooled combustion chamber (4) is composed of a membrane-type water-cooled wall around the grate, refractory bricks are laid in the contact area with the garbage, and high thermal conductivity silicon carbide castables are laid in the rest of the area to reduce the temperature of the combustion chamber to avoid coking. The flue gas recirculation and secondary air nozzles (23) are arranged in the front and rear arch areas of the water-cooled combustion ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com