Circulating fluidized bed incineration boiler for combusting solid waste

A circulating fluidized bed and solid waste technology, which is applied in fluidized bed combustion equipment, combustion product treatment, and molten fuel burning, etc. problems, to achieve the effect of inhibiting regeneration, prolonging combustion time, and meeting emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

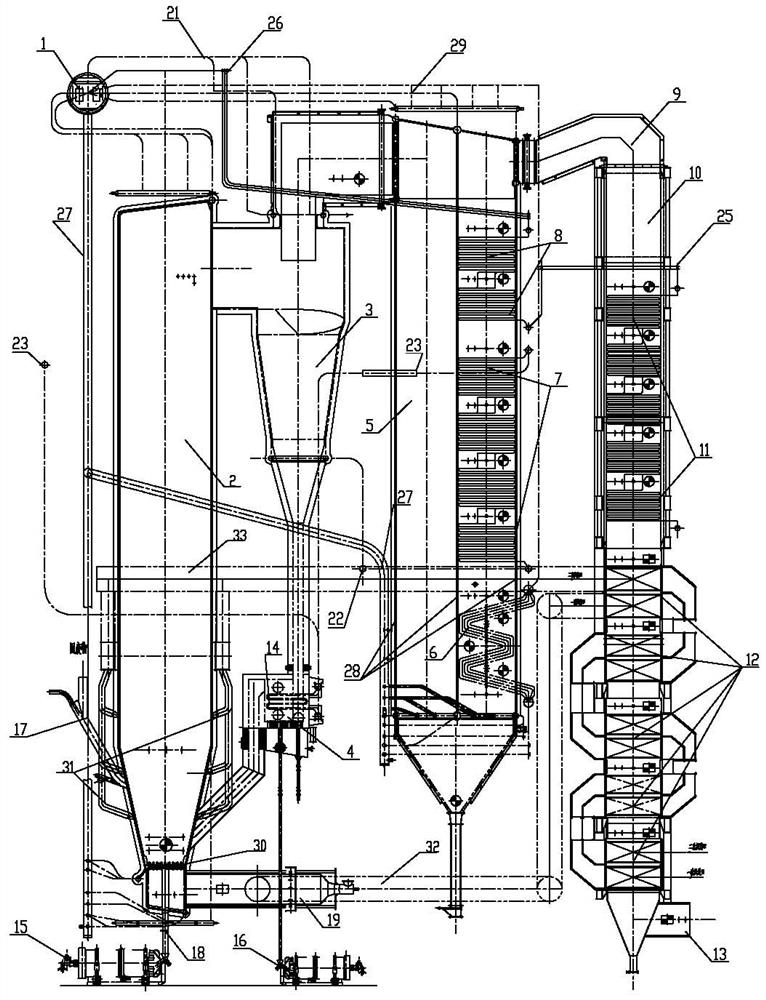

[0020] See figure 1 As shown, a circulating fluidized bed incineration boiler for burning solid waste, which includes a furnace 2, a vapor-cooled separator 3, and a tail flue arranged in sequence, and a feeding device is arranged between the vapor-cooled separator 3 and the furnace 2 4. A feed pipe 17 and a secondary air duct 31 are provided on the side wall of the furnace 2, a fluidized bed 30 is provided at the bottom of the furnace 2, an ignition device 19 and primary air are installed at the fluidized bed 30, and the furnace 2 is composed of a water-cooled wall , the fire-facing surface of the furnace is laid with a refractory material layer. The air distribution plate opening rate of the fluidized bed 30 is 2%-4%. The air distribution boards are arranged in staggered rows. Slag pipe 18, the slag pipe 18 is connected to the slag cooler 15, at least two slag pipes 18 are arranged along the width direction of the furnace, the diameter of the slag pipe 18 is greater than 250m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com