Pulverized coal burner and boiler having same

A pulverized coal burner, pulverized coal technology, applied in the direction of burners, burners burning powder fuel, using multiple fuels, etc., to achieve good high temperature resistance and thermal shock resistance, good high temperature resistance and heat resistance Shock resistance, avoiding the effect of high temperature corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

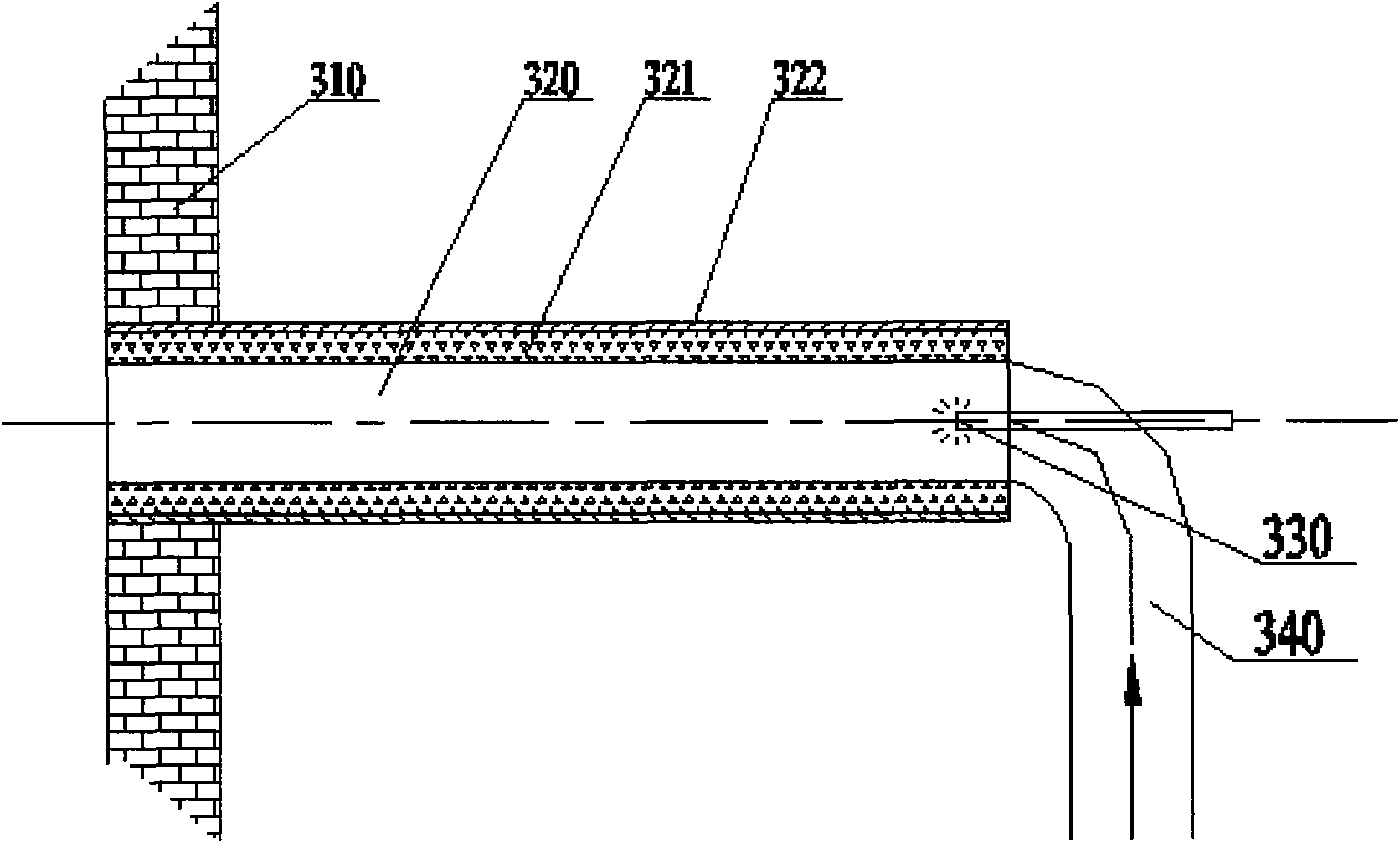

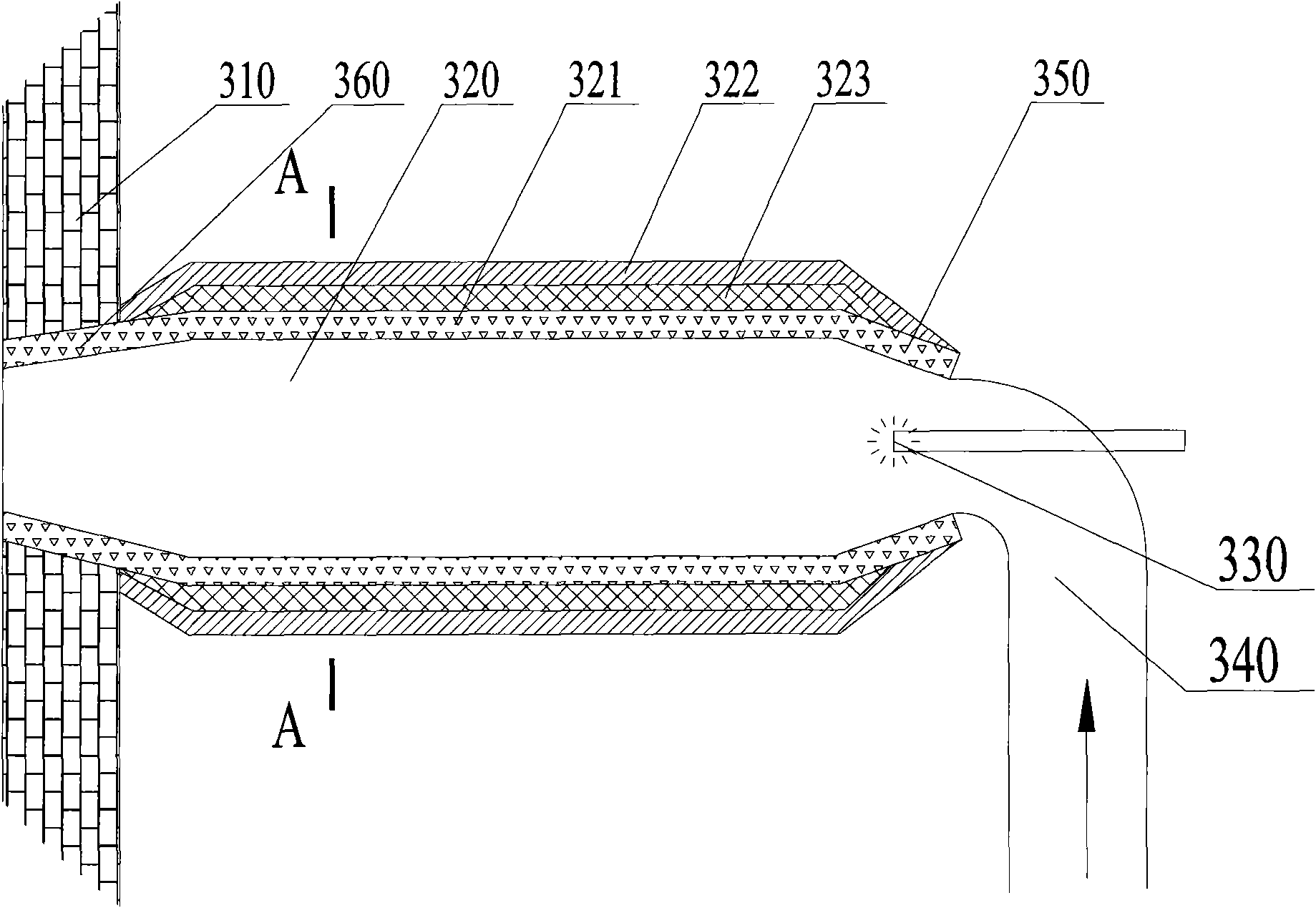

[0038] The technical solution provided by the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this section is only an exemplary and explanatory description, and should not have any limitation on the protection scope of the present invention.

[0039] It should be noted that in this section, the axial direction is the direction consistent with the flow direction of the pulverized coal in the internal combustion chamber, and the horizontal direction is the direction perpendicular to the axial direction; and the direction of the pulverized coal flow is taken as a reference, and the position near the inlet of the internal combustion chamber is the front. The position far away from the inlet of the internal combustion chamber is rear.

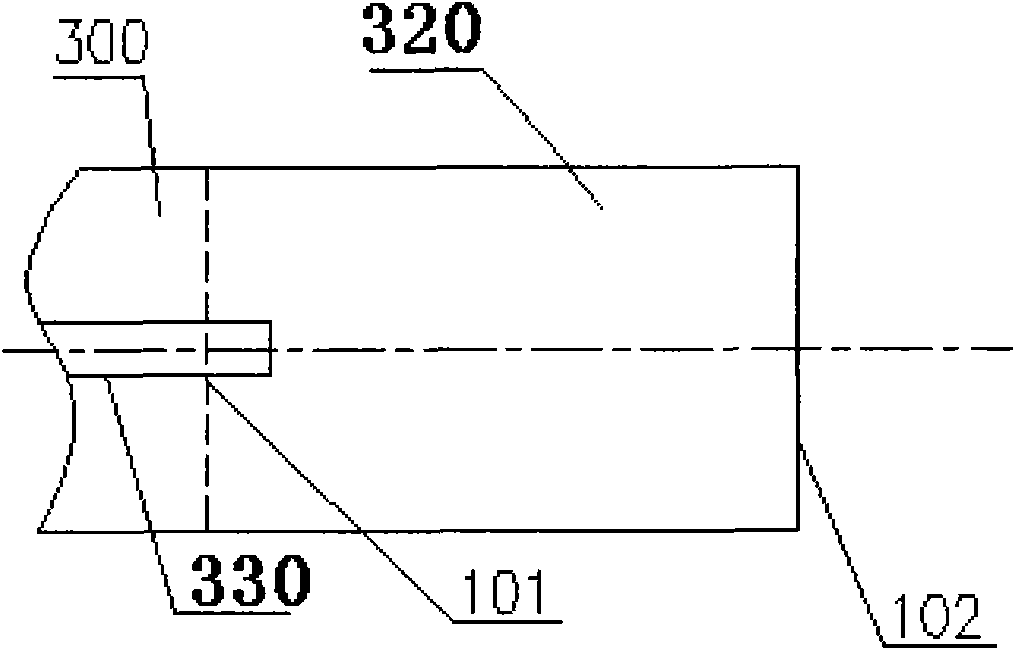

[0040] figure 2 This illustrates the axial cross-sectional structure of the pulverized coal burner provided in the first embodiment of the present invention. The pulverized coal burne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com