Boiler apparatus for preventing high temperature corrosion of water screen and method therefor

A technology for high-temperature corrosion and boiler equipment, applied in the field of boilers, can solve the problems of boiler safe and stable operation, large investment, short protection period, etc., achieve the effect of increasing operation and maintenance costs, convenient operation and management, and solving high-temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

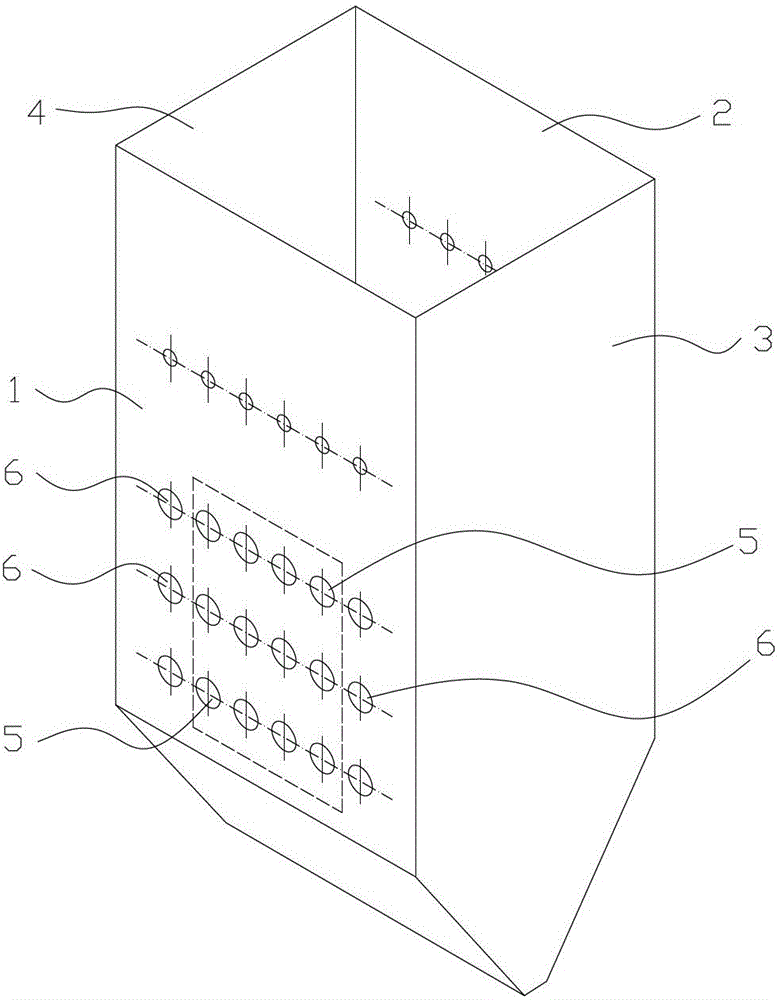

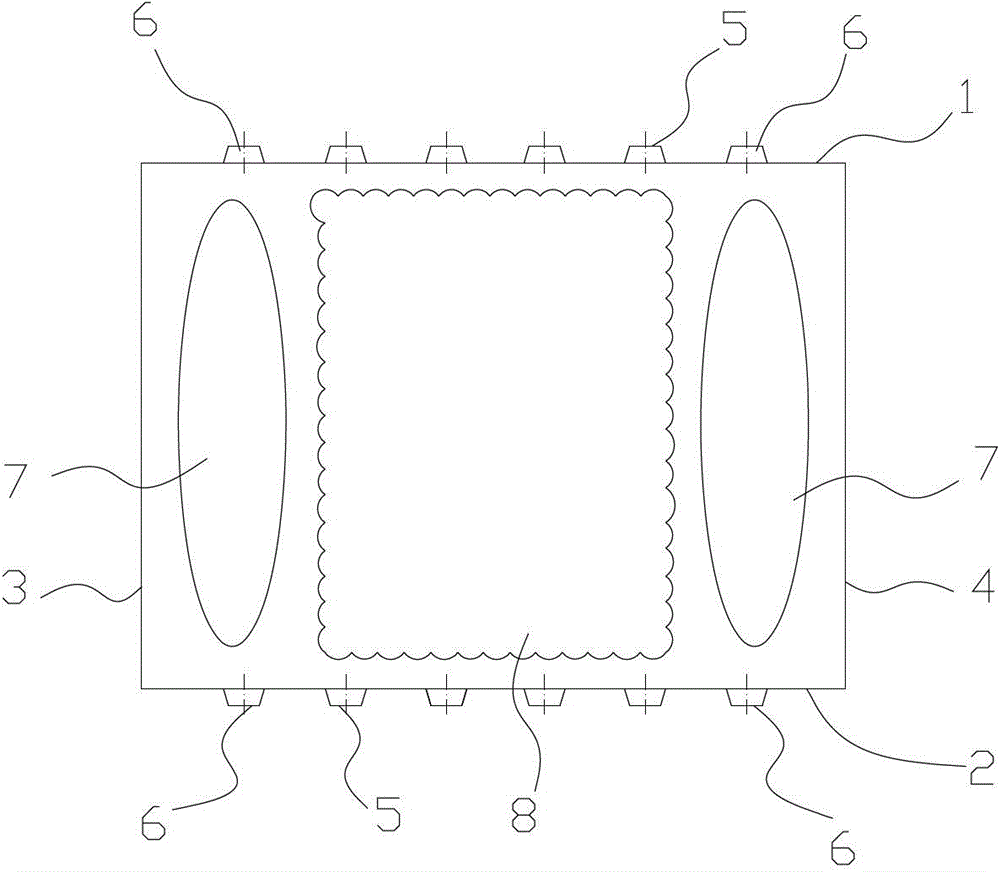

[0023] Such as figure 1 As shown, a boiler device for preventing high-temperature corrosion of water-cooled walls includes a furnace body, a low-nitrogen swirl burner 5, and a high-nitrogen swirl burner 6. The furnace body includes a front wall 1, a rear wall 2, and a left wall 3. The right side wall 4, the high nitrogen swirl burner 6 is installed on the front wall 1 and the rear wall 2 near the left side wall and the right side wall, and the low nitrogen swirl burner 5 is installed on the front wall 1. The middle area on the back wall 2 away from the left wall and the right wall.

[0024] Depend on figure 1 It can be seen that in this embodiment, the low-nitrogen swirl burners 5 are arranged in the middle area of the front wall 1 and the rear wall 2 away from the left and right walls, arranged in three rows, and the low-nitrogen swirl burners in each row High nitrogen swirl burners 6 are arranged near the left wall and the right wall of the flow burner 5 . There are twe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com