Sintering trolley

A technology for sintering trolleys and car bodies, which is applied to furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of high temperature erosion of the sintering trolley car body and wheels, and achieve the effect of strengthening the flame blocking effect of the igniter, prolonging the Service life, the effect of reducing high temperature erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

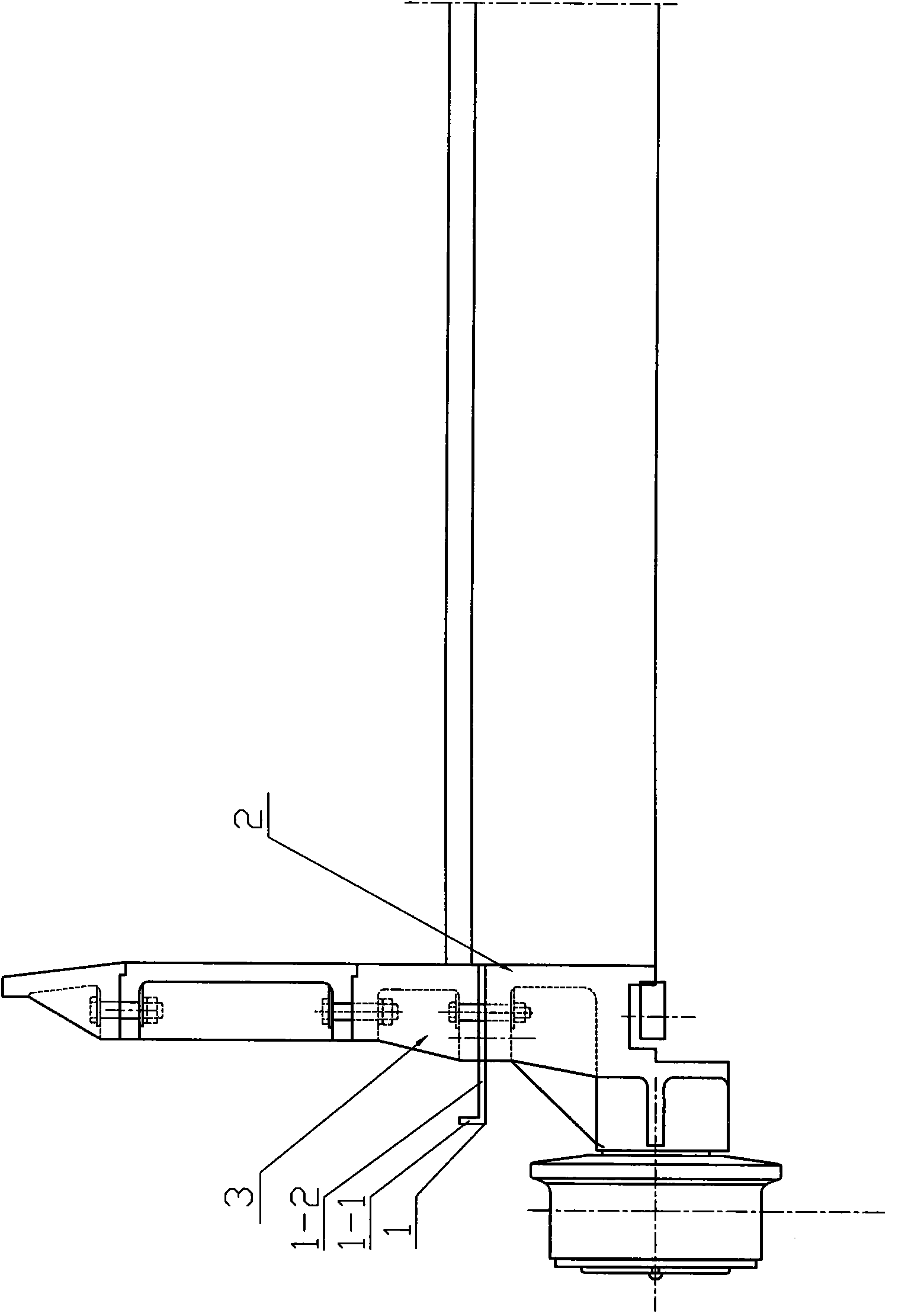

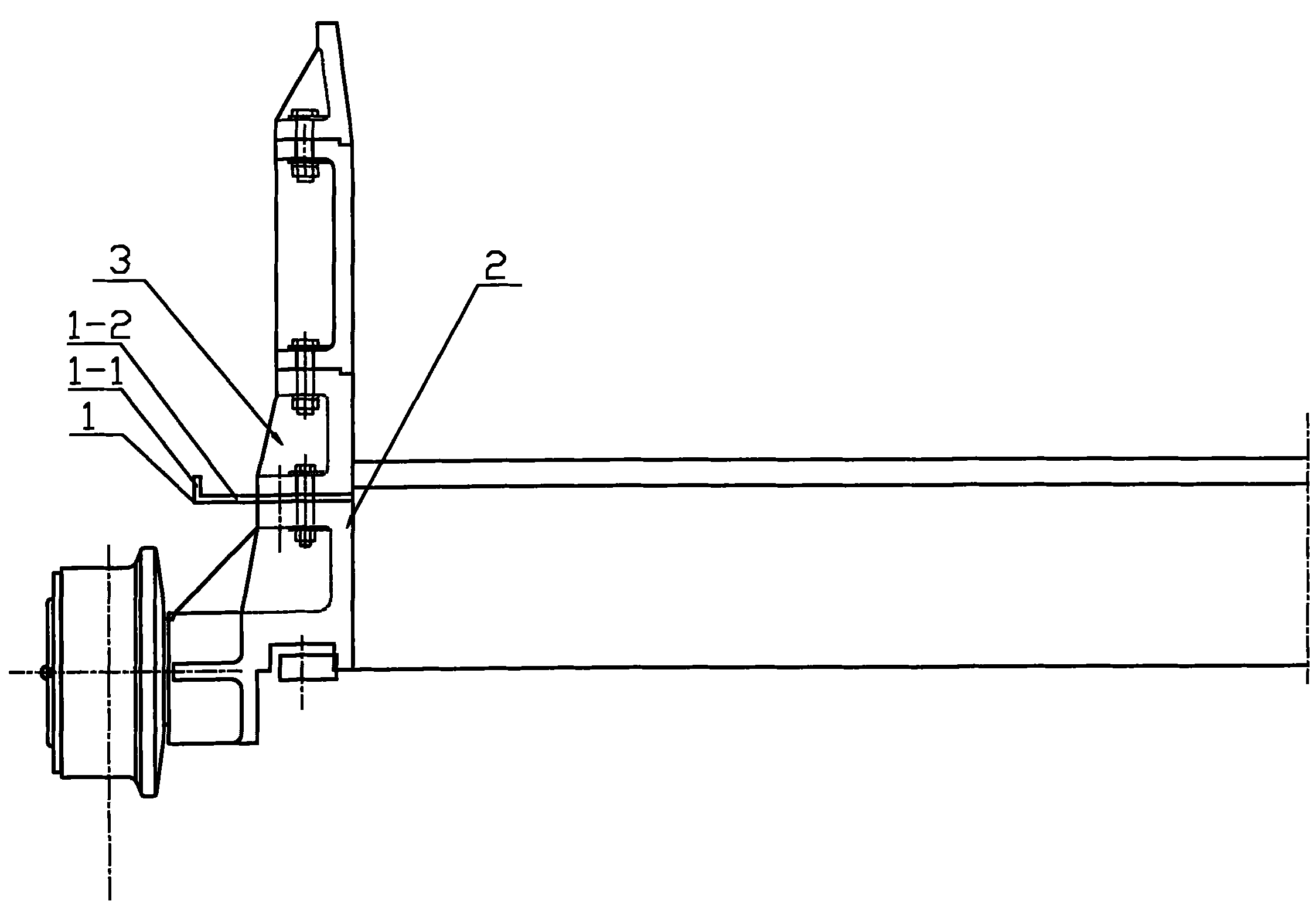

[0010] Such as figure 1 As shown, it is a sintering trolley, which includes a trolley body 2, and the upper sides of the trolley body 2 are fixedly connected with the lower fence 3 respectively, and a durable An L-shaped fire baffle 1 made of heat-resistant and corrosion-resistant materials, the L-shaped fire baffle 1 includes a longitudinal section 1-1 and a transverse section 1-2, the longitudinal section 1-1 and the transverse section 1-2 are vertically arranged, the longitudinal section 1 The lower end of -1 is fixedly connected to the outer end of the transverse section 1-2, and the inner end of the transverse section 1-2 is arranged between the trolley body 1 and the lower fence 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com