A kind of smelting method of high carbon aluminum killed steel

A technology for high-carbon aluminum killed steel and a smelting method, applied in the field of steelmaking, can solve the problems of increasing the cost of refractory materials and the influence of the purity of molten steel, and achieve the effects of improving the purity, reducing high-temperature erosion, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: The smelting method of the high-carbon aluminum-killed steel adopts the following specific processes.

[0017] (1) The production steel type is GCr15A-B2 high-carbon aluminum killed steel for a casting time, the section of the continuous casting machine is 200mm*200mm, and the standard requirement for its main chemical (smelting) composition is (wt): C 0.95%~1.05% , Si 0.15%~0.35%, Mn 0.25%~0.45%, P≤0.020%, S≤0.020%, Cr 1.40%~1.64%, Al≤0.050%, and the balance is Fe and unavoidable impurities.

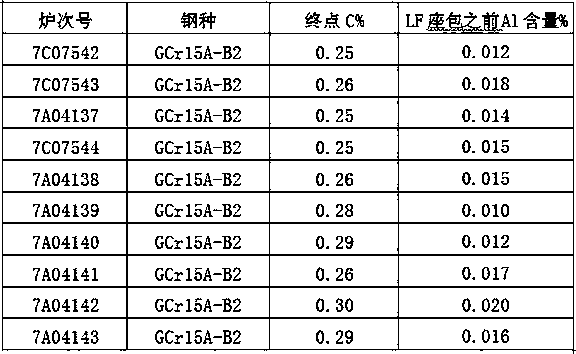

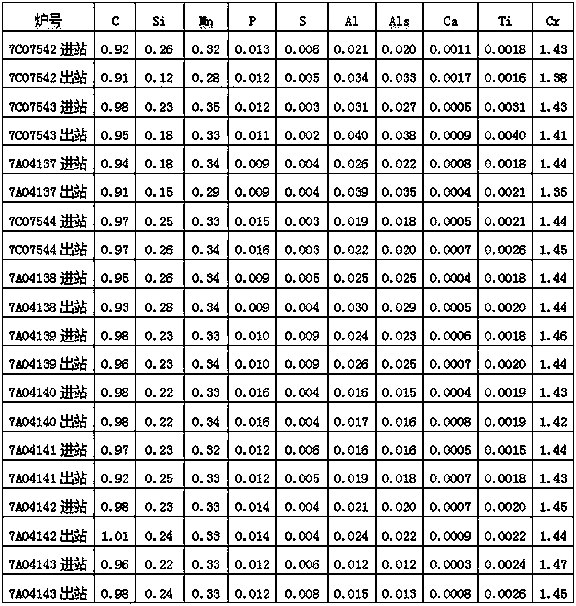

[0018] (2) Converter process: the C content at the end point of the molten steel is controlled at ≥0.25wt%, and the Al content before the LF process is controlled at ≥0.010wt%, and other components are controlled according to the requirements of the work instruction; the carbon content at the end point of the converter is shown in Table 1.

[0019] Table 1: Converter endpoint carbon (wt%)

[0020]

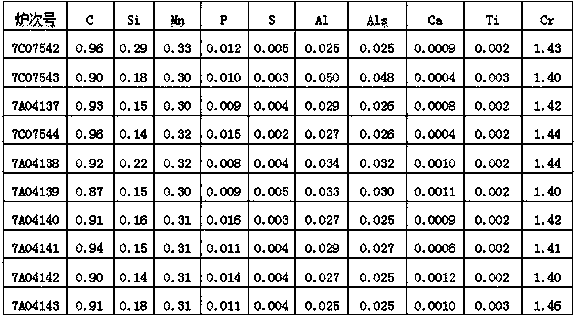

[0021] (3) LF refining process: the temperature measurement ran...

Embodiment 2

[0033] Embodiment 2: The smelting method of the high-carbon aluminum-killed steel adopts the following specific processes.

[0034] (1) Production of steel GCr15-A for a certain casting time, continuous casting machine section 200mm*200mm, the standard requirements for its main chemical (smelting) composition (wt): C 0.95% ~ 1.05%, Si 0.15% ~ 0.35% , Mn 0.25%~0.45%, P≤0.020%, S≤0.020%, Cr 1.40%~1.64%, Al≤0.050%, the balance is Fe and unavoidable impurities.

[0035] (2) Converter process: the C content at the end point of molten steel is controlled at ≥0.25wt%, and the Al content before the LF process is controlled at ≥0.010wt%, and other components are controlled according to the requirements of the work instruction; the carbon content at the end point of the converter is shown in Table 6.

[0036] Table 6: Converter endpoint carbon (wt%)

[0037]

[0038] (3) LF refining process: the temperature measurement range of molten steel entering the station for each heat is 1486-1...

Embodiment 3

[0050] Embodiment 3: The smelting method of the present high-carbon aluminum-killed steel adopts the following specific processes.

[0051] (1) Production of steel grade GCr15 for a certain casting time, continuous casting machine section 200mm*200mm, the standard requirements for its main chemical (smelting) composition (wt): C 0.95%~1.05%, Si 0.15%~0.35%, Mn 0.25%~0.45%, P≤0.020%, S≤0.020%, Cr 1.40%~1.64%, Al≤0.050%, the balance is Fe and unavoidable impurities.

[0052] (2) Converter process: Control the C content at the end point of molten steel at ≥0.25wt%, and ensure that the Al content before the LF process is controlled at ≥0.010wt%, and other components are controlled according to the requirements of the work instructions; the carbon content at the end point of the converter is shown in Table 11.

[0053] Table 11: Converter endpoint carbon (wt%)

[0054]

[0055] (3) LF refining process: the temperature measurement range of molten steel entering the station for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com