Temperature monitoring system of granulator

A technology of monitoring system and granulator, which is applied to thermometers, thermometers and instruments using electric/magnetic elements that are directly sensitive to heat, can solve problems such as large energy consumption, high water consumption, and environmental pollution. Line problems, prolong service life, reduce the effect of high temperature erosion and chemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

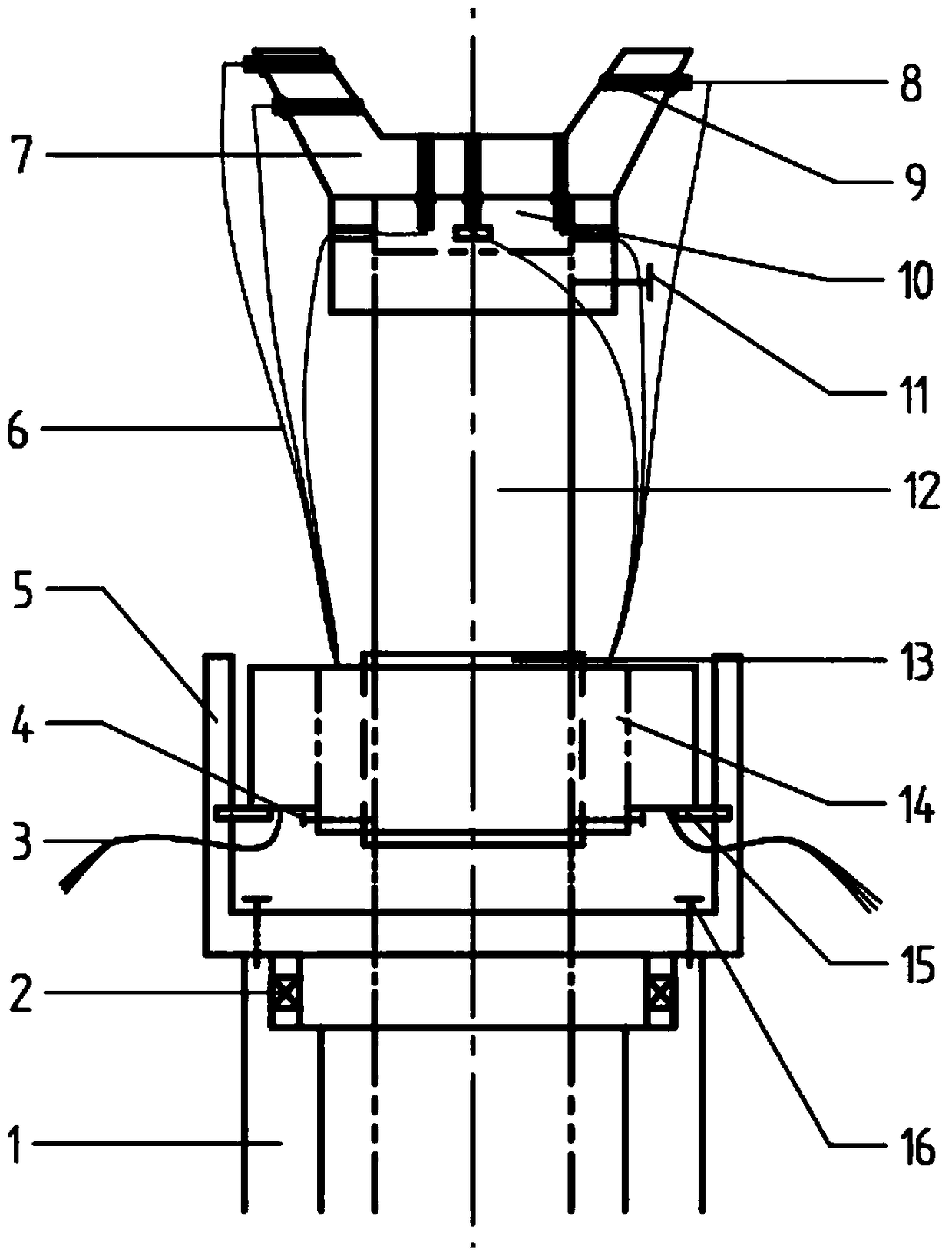

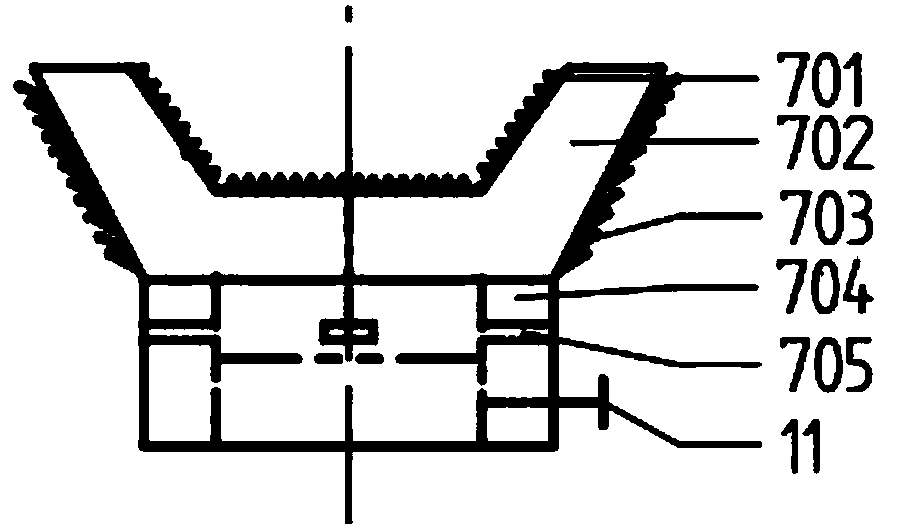

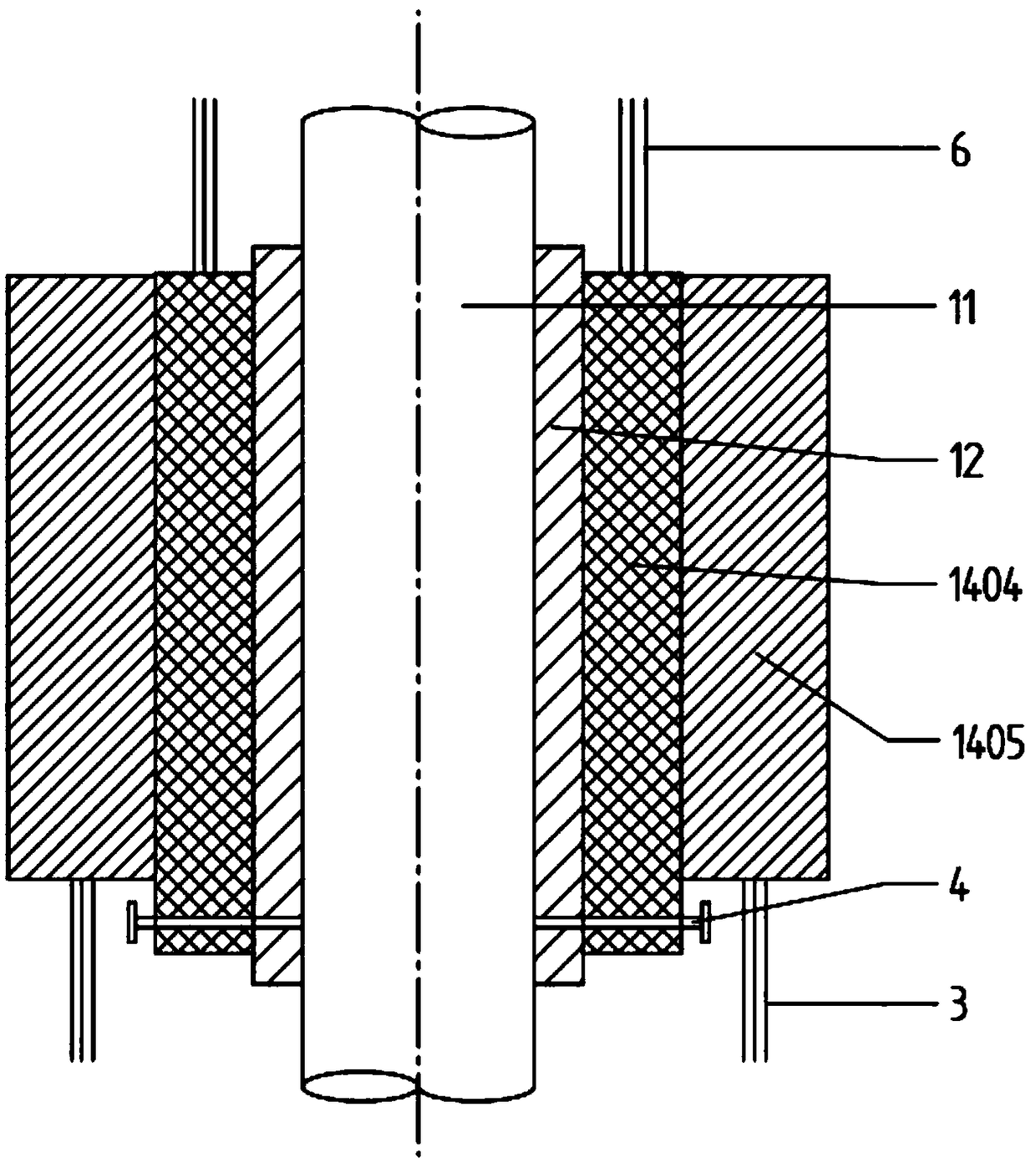

[0016] see Figure 1 to Figure 3 , a temperature monitoring system for a granulator, comprising a granulator 7, a thermocouple 8, a rotating shaft 12, a through-aperture conductive slip ring 14, a rotation stop device 5, a bearing 2 and a shaft sleeve 1; the bearing 2 is set on the rotating shaft 12 Above, the bearing 2 is fixed by the shaft sleeve 1, and the shaft sleeve 1 is sleeved on the middle and lower part of the rotating shaft 12; the granulator 7 includes a granulator main body 702 and a hollow cylindrical sleeve 704; the granulator main body 702 is cup-shaped or disc-shaped shape; the granulator main body 702 is provided with a number of thermocouple installation holes, and the installation holes are arranged asymmetrically and evenly. The thermocouple 8 is covered with a protective sleeve 9 and fixed in the installation hole; the thermocouple 8 detects the temperature of the inner surface of the granulator main body 702 .

[0017] The bottom of the granulator main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com