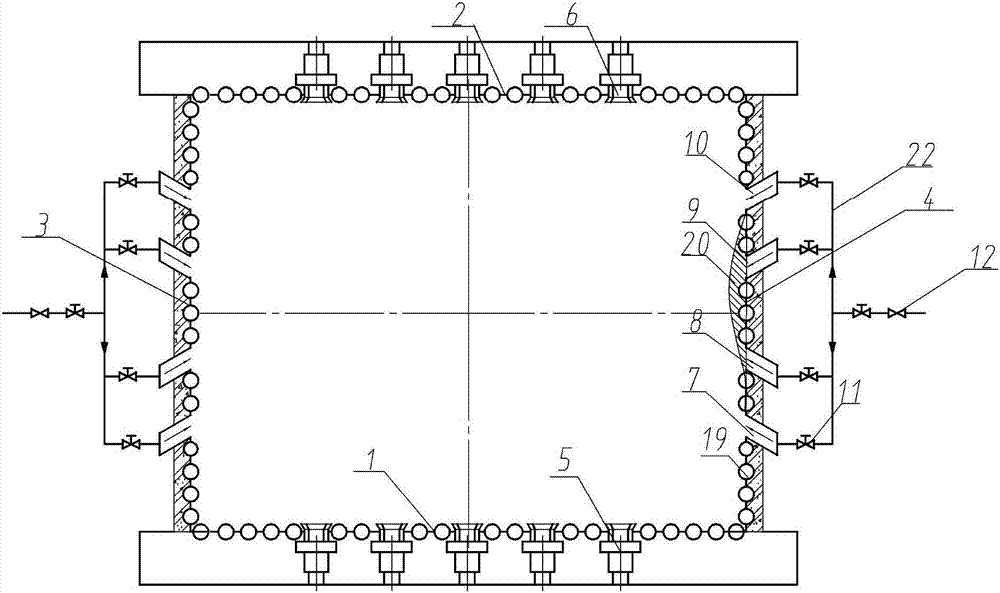

Boiler water wall air film protection device

A protection device and water-cooled wall technology, applied in the boiler field, can solve the problems of burning loss, affecting the rigidity of the wall-attached wind, and cannot prevent high-temperature corrosion of the water-cooled wall, etc., to solve high-temperature corrosion, facilitate technical transformation, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

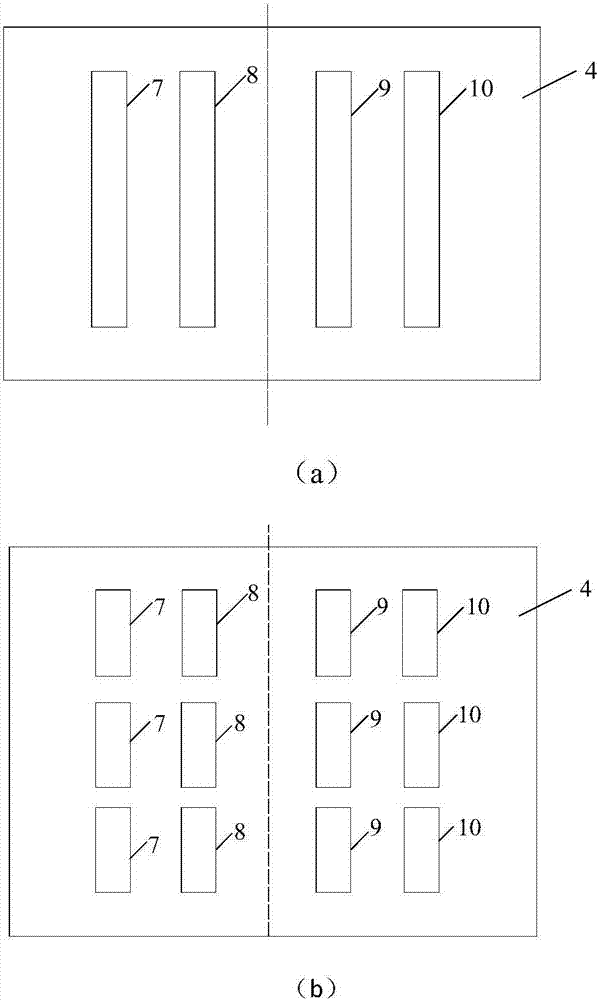

[0039] In this embodiment, a number of water-cooled walls 19 and their fins of the traditional boiler are cut off for the front and rear wall opposed combustion boilers, and the furnace wall is arranged on the right wall upstream of the high-temperature flame and flue gas pulverized coal flow in the water-cooled wall area of the boiler. Be the slit type first tuyere 7 of certain angle. The slit-type first tuyere 7 forms a certain angle with the center line of the water-cooled wall 6, and the included angle is 30-45° or within an appropriate angle. The slit-type first tuyere 7 can be arranged in a whole section or in sections. see figure 2 (a), the entire arrangement is specifically that the height of the first tuyere 7 is the distance from the swirl burner at the lowest level of the boiler to the overfired air burner, see figure 2 (b), segmented arrangement is specifically to divide the first tuyeres 7 into several sections along the height direction, and the several sec...

Embodiment 2

[0045] see Figure 4 , for the counter-firing boiler, the right wall of the traditional boiler is divided into three sections: the right wall I section 13, the right wall II section 14 and the right wall III section 15, and the right wall II section 14 is prone to water-cooled wall In the area subject to high temperature corrosion, the distance from section 14 of the right wall II to the front wall 1 and the rear wall 2 is 1 / 3 of the depth of the furnace. Compared with traditional boilers, section II of the right wall 14 moves 150 mm to 200 mm outside the furnace, and forms a fifth tuyere 16 with section I of the right wall, section II of the right wall and section III of the right wall 15 The eighth tuyere 23 is formed therebetween, the fifth tuyere 16 is located upstream of the front wall burner 5 flame and flue gas flow, and the eighth tuyere 23 is located upstream of the rear wall burner 6 flame and flue gas flow. The heights of the fifth tuyere 16 and the eighth tuyere 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com