Anti-corrosion and noise reduction chimney for ships

A technology for ships and chimneys, which is applied in the field of anti-corrosion and noise-reducing chimneys for ships. It can solve the problems that the temperature drop range cannot be accurately controlled and adjusted, the cooling effect of heat transfer fluid circulation is limited, and the cooling effect is not obvious. High temperature corrosion problem, the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

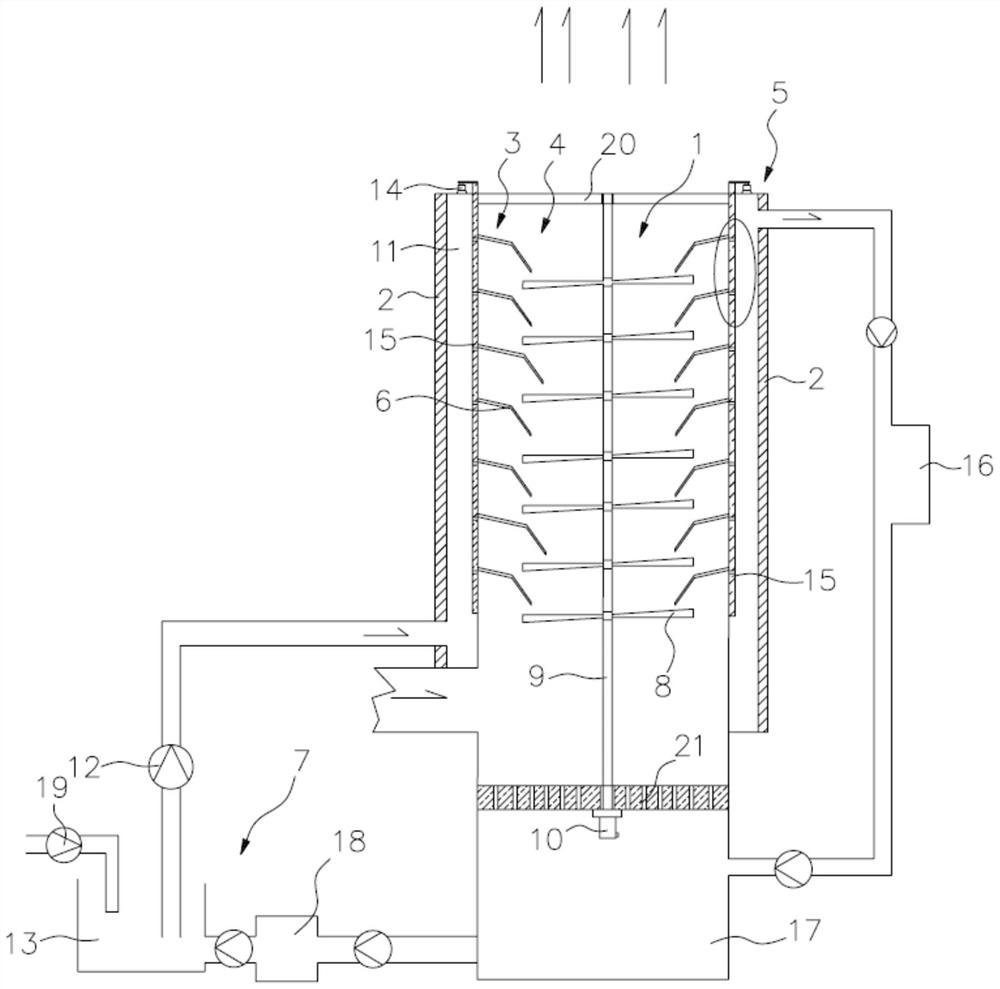

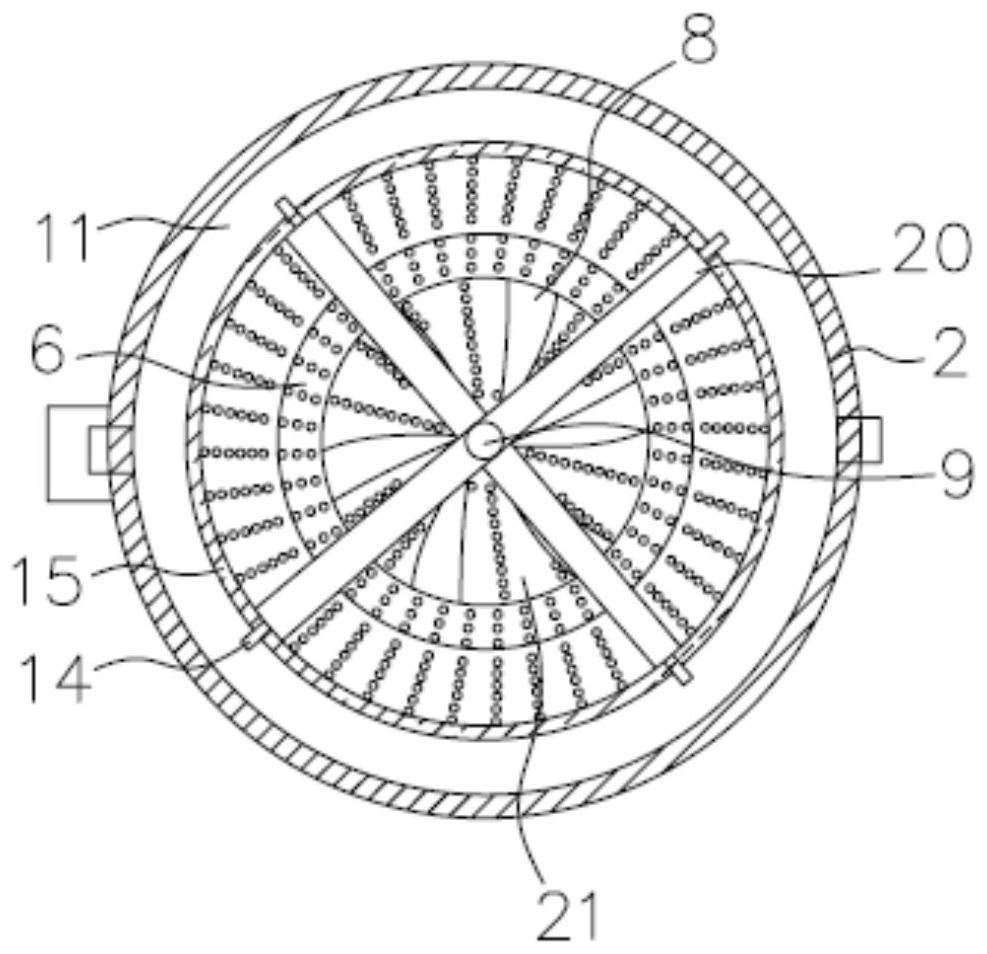

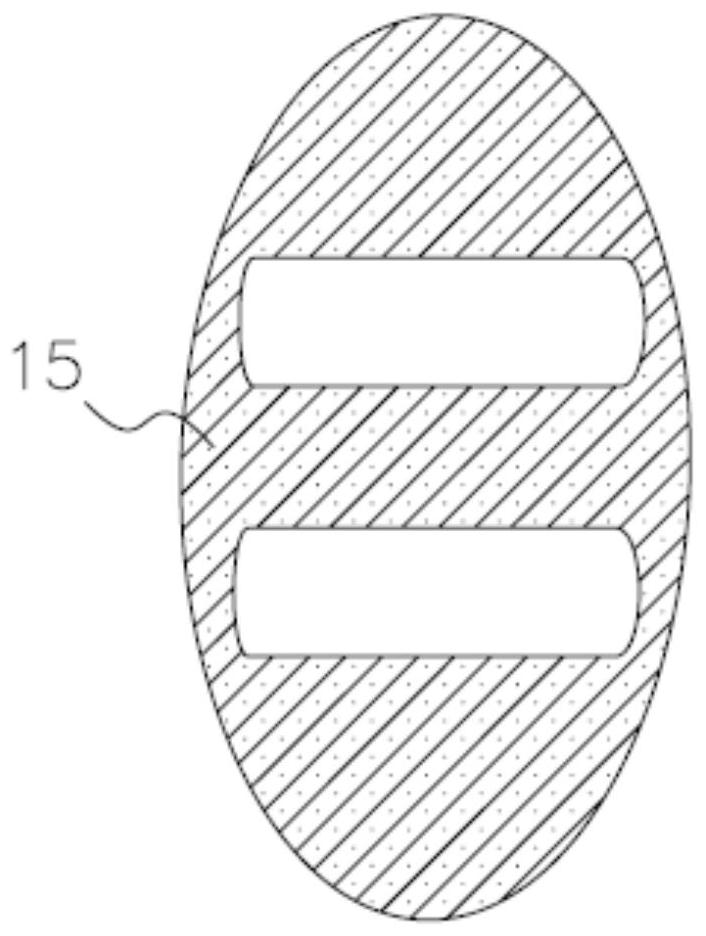

[0017] As shown in the figure, an anti-corrosion and noise-reducing chimney for ships includes a chimney for exhausting exhaust gas, including a conversion device 1 arranged on the central axis of the chimney for converting the kinetic energy of exhaust gas into electrical energy, and is arranged on the inner wall of the chimney. The internal cooling device 3 for reducing the internal temperature of the chimney and the smoke, the muffler device 4 for reducing the noise of the chimney, the external cooling device 5 provided outside the chimney, the heat insulation layer 2 provided on the surface of the external cooling device, and the cooling liquid The circulation purification device 7 and the controller used in the purification cycle.

[0018] The exhaust gas generated by the main engine enters the chimney through the exhaust pipe, and the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com