Full-automatic online pulverized coal sampling device and sampling method thereof

A sampling device, fully automatic technology, applied in the direction of sampling device, sampling, measuring device, etc., can solve the problems of no speed and position control, unable to realize constant speed sampling, unable to realize equal area ring sampling, etc., to achieve the goal of improving representativeness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., are only appended The directions in the figure are only used to explain and illustrate the present invention, not to limit the protection scope of the present invention.

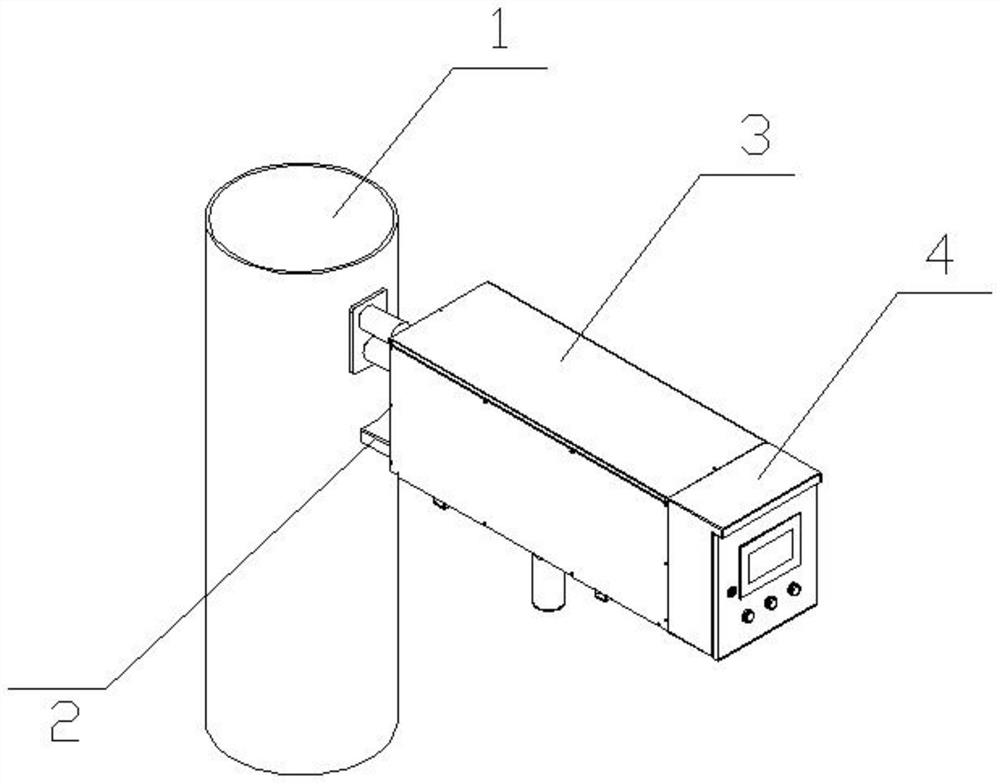

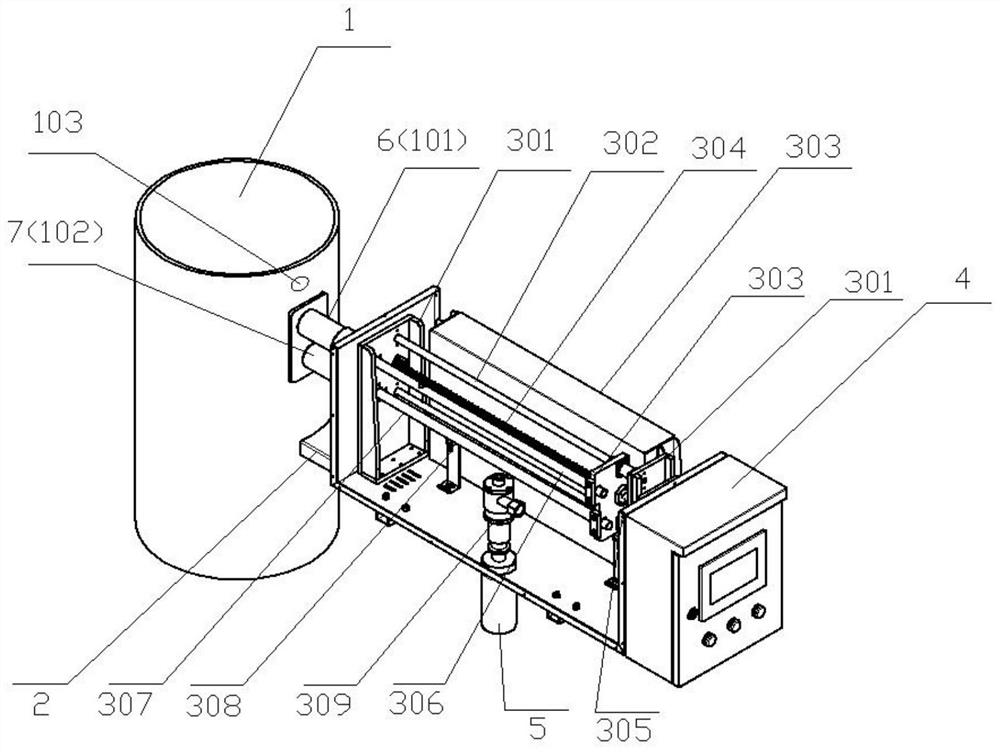

[0021] see figure 1 and figure 2 , the composition structure of the automatic pulverized coal online sampling device of the present invention is given, such as figure 1 As shown, the support 2 installed on the pulverized coal pipeline 1, the sampling box 3 installed on the support 2, the electrical control box 4 connected to the sampling box, the sampling bottle 5 installed below the sampling box;

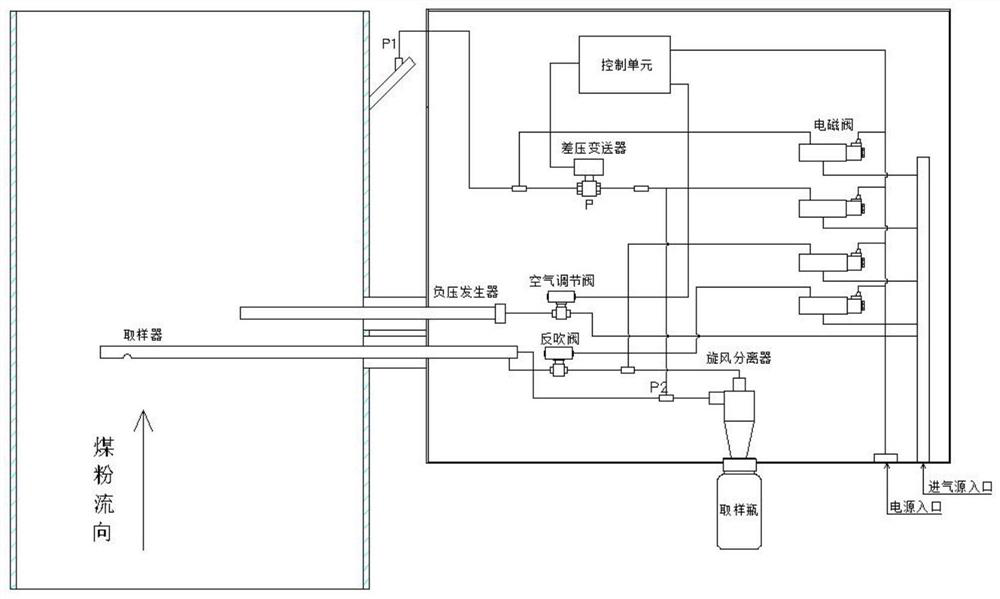

[0022] The pulverized coal pipeline 1 is provided with a sampling hole 101 and an air hole 102, and a pressure sensor 103 is installed on the pulverized coal pipeline 1 for monitoring the pressure of the gas-powder mixture in the pulverized coal pipeline; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com