Pulverized coal preparation system and method with air-blew pulverized coal heat measurement and control functions

A technology of air-sent and pulverized coal, applied in the field of coal powder preparation system with heat measurement and control of air-sent pulverized coal, which can solve problems such as waste of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

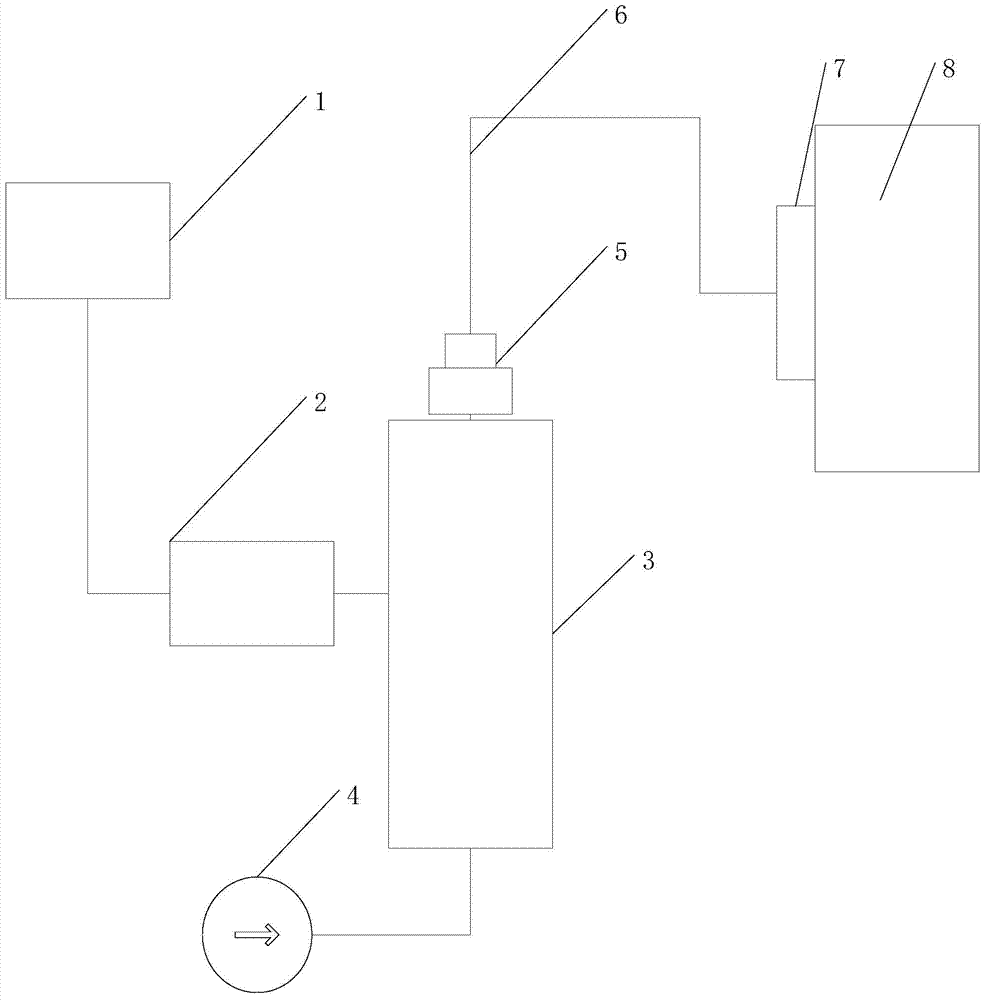

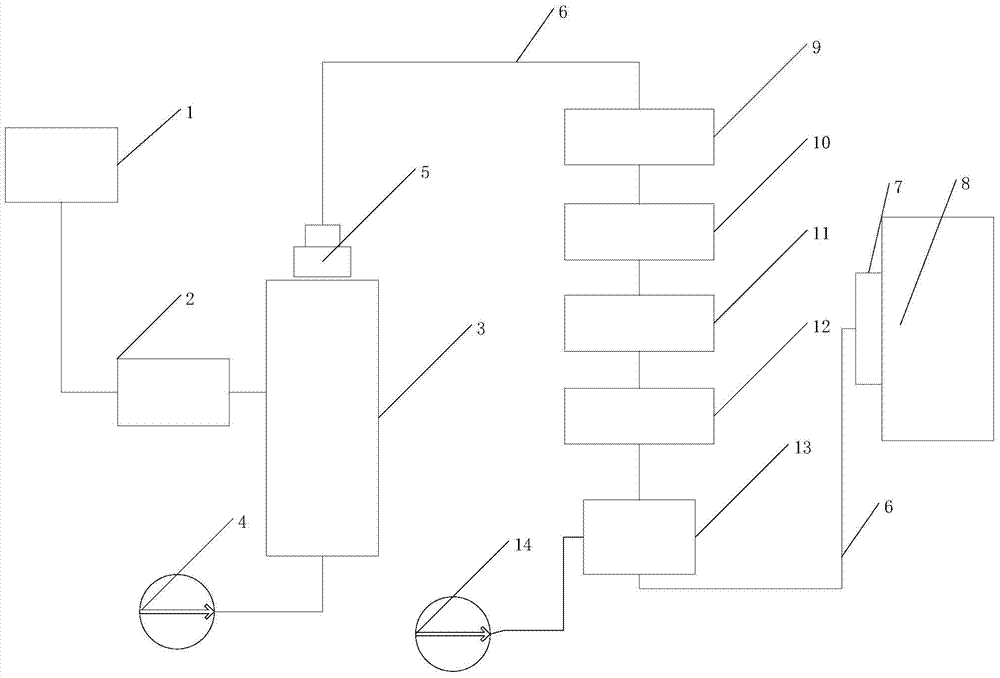

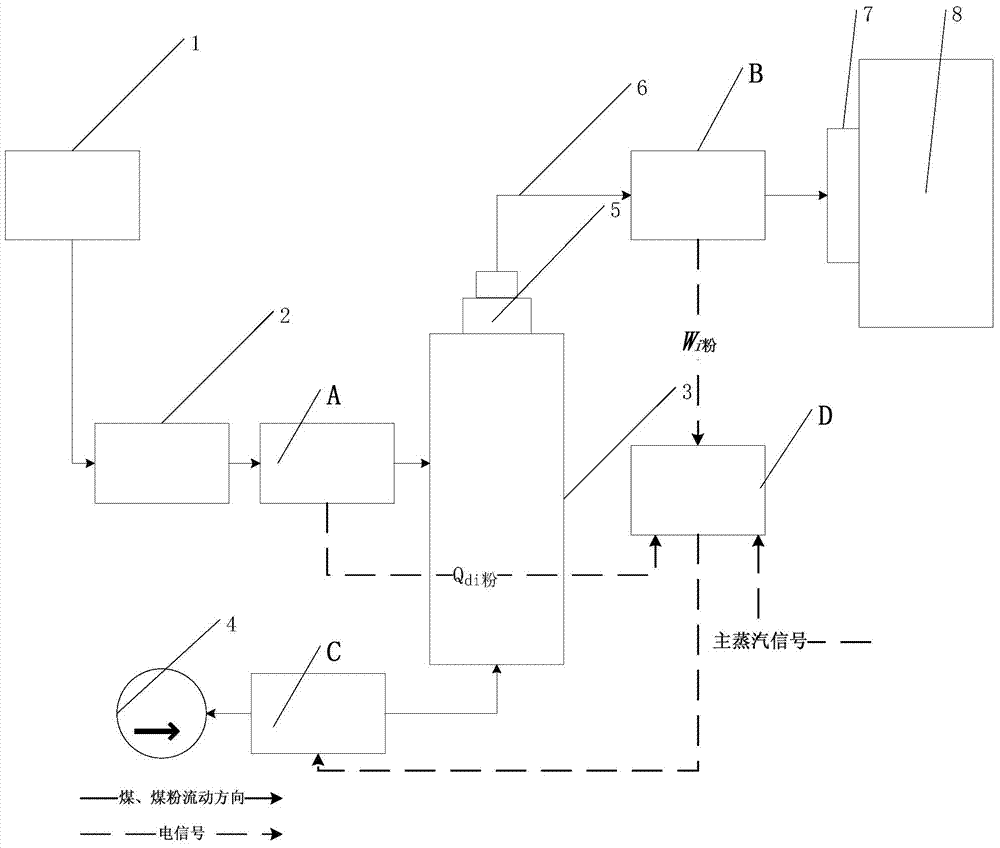

[0079] Such as Figure 2A , 2B Shown is a schematic structural view of the pulverized coal preparation system with heat measurement and control of pulverized coal fed by wind according to the present invention.

[0080] Compared with the prior art, the present invention is Figure 1A The rear of the coal feeder 2 has added "heat coal supply system A" or in Figure 1B In front of the powder feeder 12, a "heat coal supply system A" has been added. In addition, in Figure 1A with Figure 1B The air-delivered pulverized-coal pipeline 6 has been equipped with an air-delivered pulverized-coal weighing instrument B and an air speed regulating controller C has been installed on the pipeline of the blower fan. In addition, a data processing controller D is provided.

[0081] The heat coal supply system A is used to transport raw coal for the coal mill, and the heat coal supply system measures the calorific value, moisture and weight of the raw coal to calculate the heat J of the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com