Control method of running of pulverized coal burner of pulverized coal pressurization gasification reaction device

A technology for pressurized gasification and reaction device of pulverized coal, which is applied in the field of coal chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

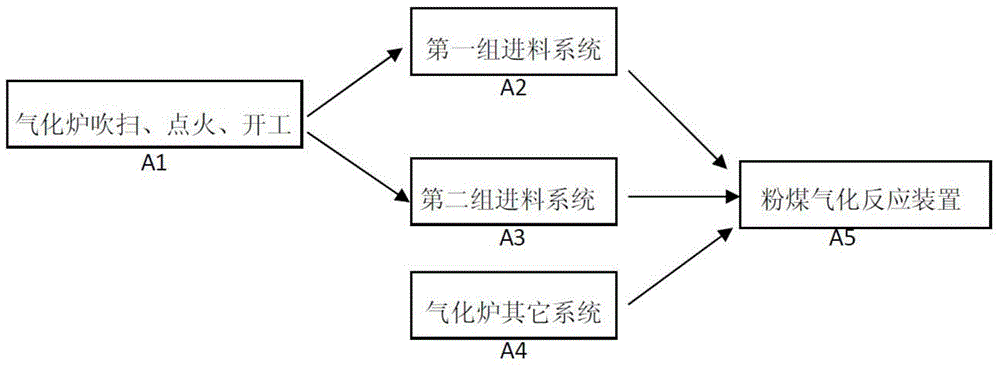

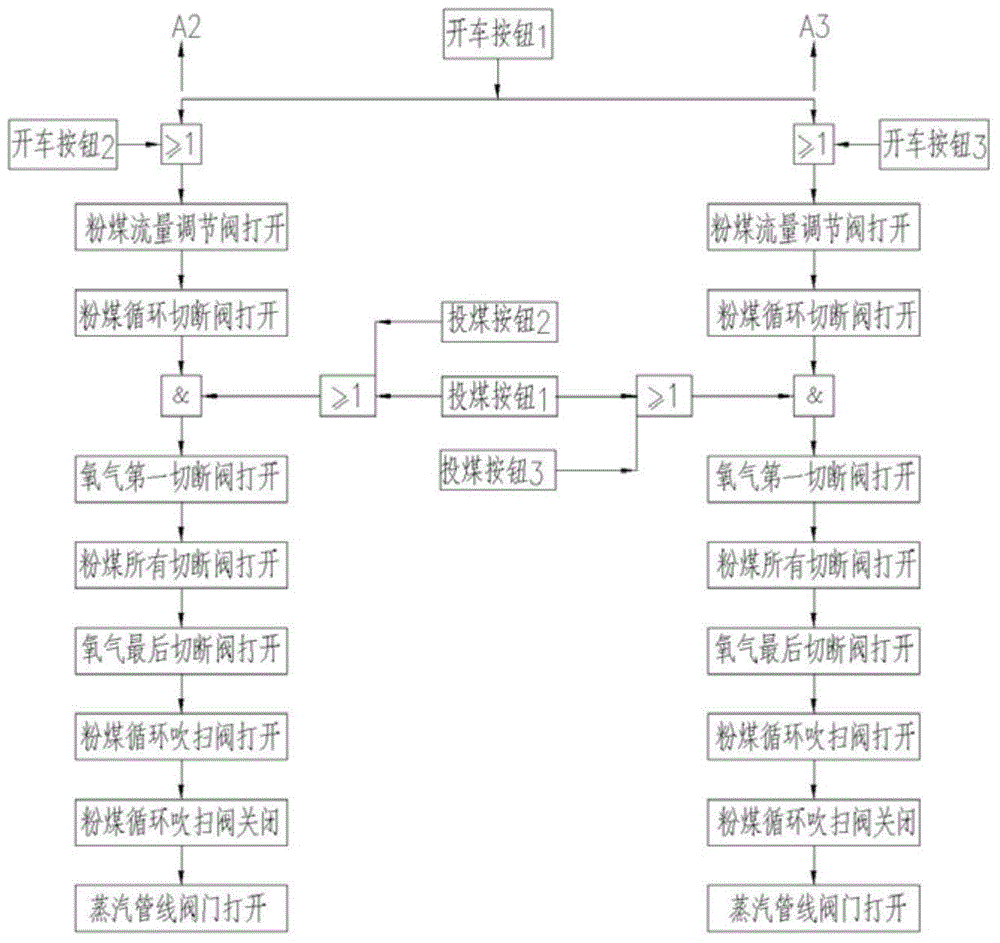

[0027] Such as figure 1 As shown, after the start-up burner is running and the pressure is increased to 1.0MPaG and 800°C, the two sets of feed systems A2 and A3 are activated at the same time or the pulverized coal circulation is activated separately. When the coal feeding conditions are met, A2 and A3 are activated simultaneously or respectively. Put pulverized coal and oxygen into the pulverized coal gasification reaction device A5, stop the start-up burner, and withdraw the pulverized coal from circulation, and continue to increase the pressure and temperature of the pulverized coal gasification reaction device to make it at the predetermined pressure and temperature work. If the two feeding systems feed separately, the oxygen pipeline and pulverized coal pipeline of the second feeding system should be fed with protective gas before feeding the first feeding system.

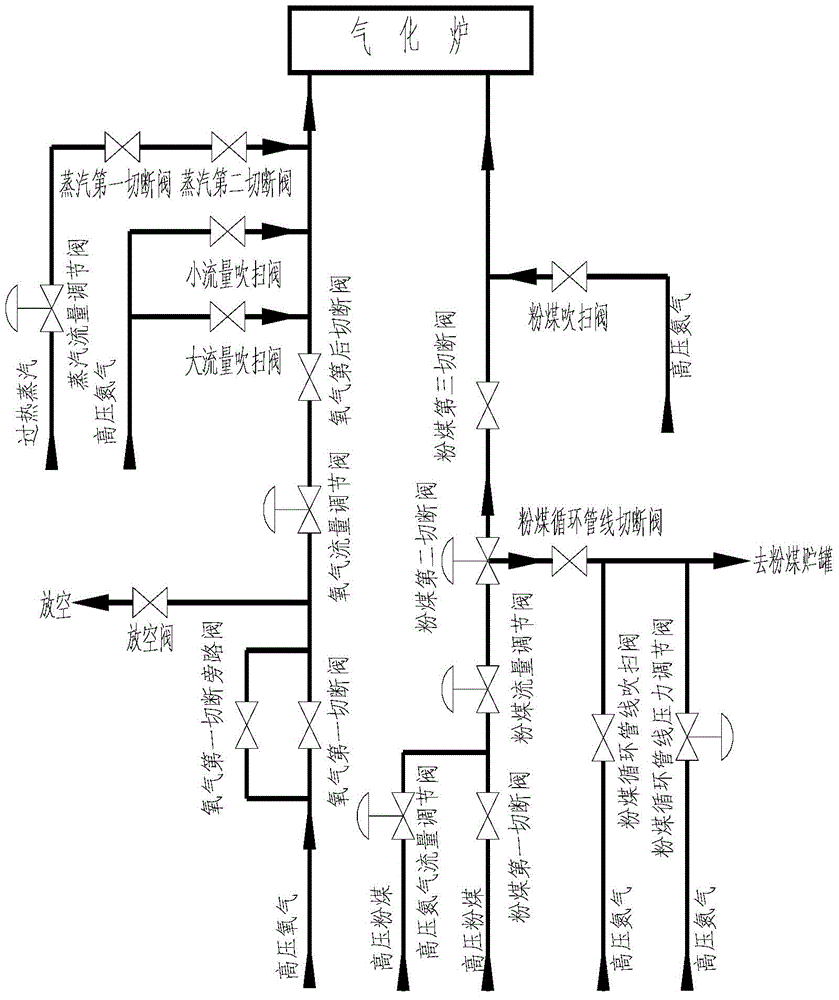

[0028] Such as figure 2 Shown: The first feed system A2 includes: an oxygen pipeline, two to four pulve...

Embodiment 2

[0038] Follow the same method as in Example 1, except that the start-up burner is operated and the pressure is increased to 0.8MPaG and 1000°C.

Embodiment 3

[0040] Follow the same method as in Example 1, except that the start-up burner is operated and the pressure is increased to 1.2MPaG and 600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com