Air staged-combustion vertical and horizontal combined arrangement type over fire air system for tangential boiler

An air classification, vertical and horizontal technology, applied in the direction of combustion equipment, lighting and heating equipment, etc., can solve the problems of poor jet rigidity, difficulty, large size, etc., to increase burnout time, eliminate smoke temperature deviation, and eliminate residual rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

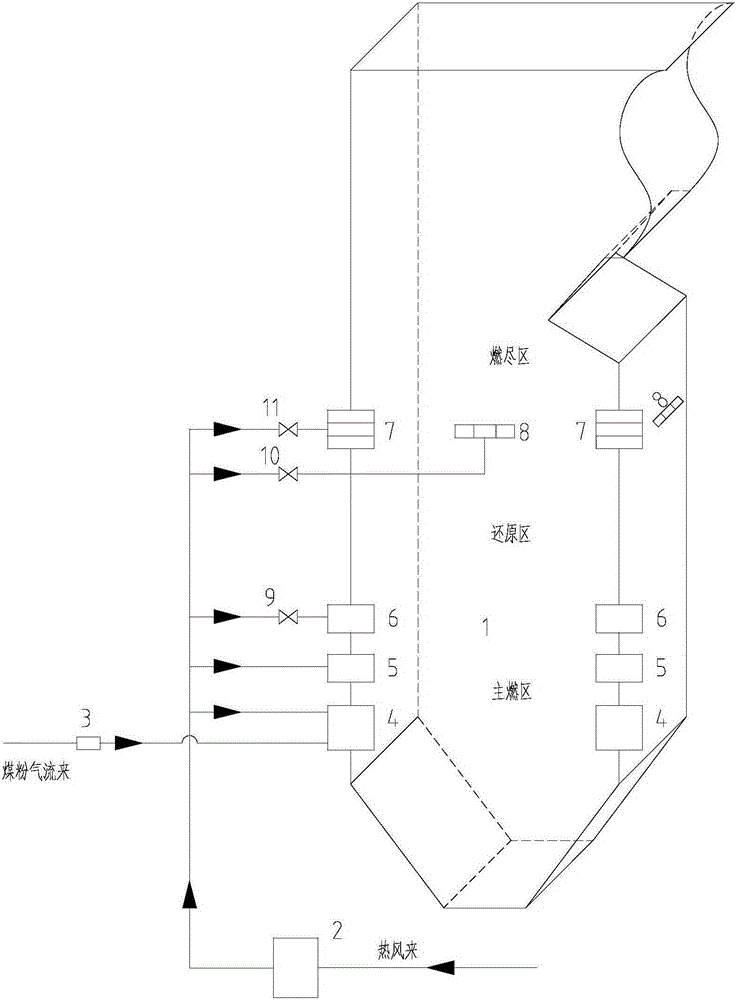

[0024] see figure 1 , a tangential boiler air staged combustion vertical and horizontal combined arrangement burn-off air system of the present invention, including furnace 1, hot air box 2, pulverized coal pipeline 3, primary air nozzle 4, secondary air nozzle 5, compact burn-off air nozzle 6 , corner separated overburning air nozzle 7, wall type separated overburning air nozzle 8, compact overburning air regulating door 9, wall type separated overburning air regulating door 10 and corner separated overburning air regulating door 11;

[0025] Among them, the furnace 1 is divided into the main combustion zone, the reduction zone and the burnout zone from bottom to top, and the primary air nozzle 4, the secondary air nozzle 5 and the compact burnout air nozzle 6 are all arranged on the furnace wall of the main combustion zone of the furnace 1 Above, the corne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com