Combined-type powdered coal pipeline compensation device

A technology for pulverized coal pipelines and compensation devices, which is applied to expansion compensation devices for pipelines, pipe components, pipes/pipe joints/fittings, etc., and can solve the eccentric wear of the inner sleeve and outer sleeve of the telescopic sleeve compensator , the roller structure loses its effect, and cannot achieve axial guidance, etc., to achieve the effect of improving coaxial matching accuracy, ensuring safety, and increasing axial compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to accompanying drawing.

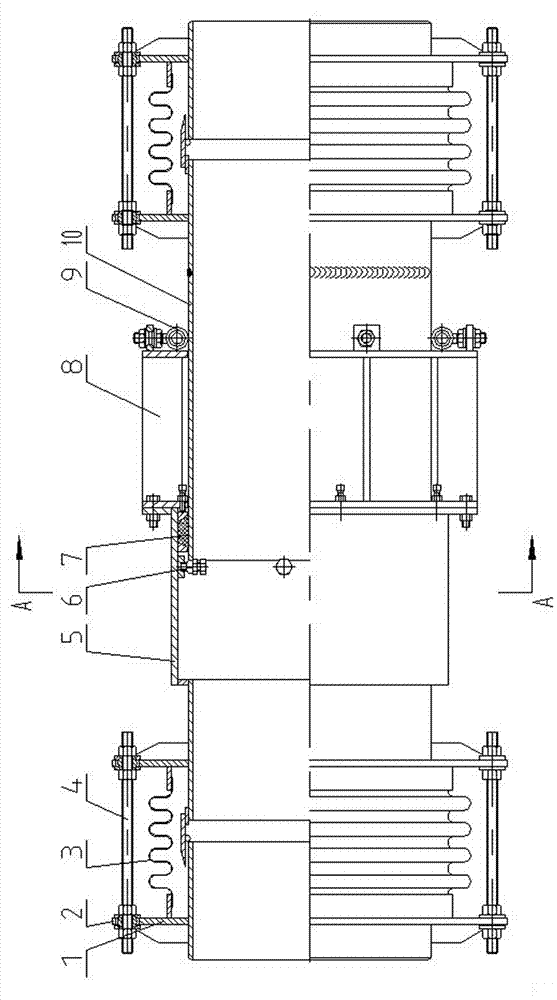

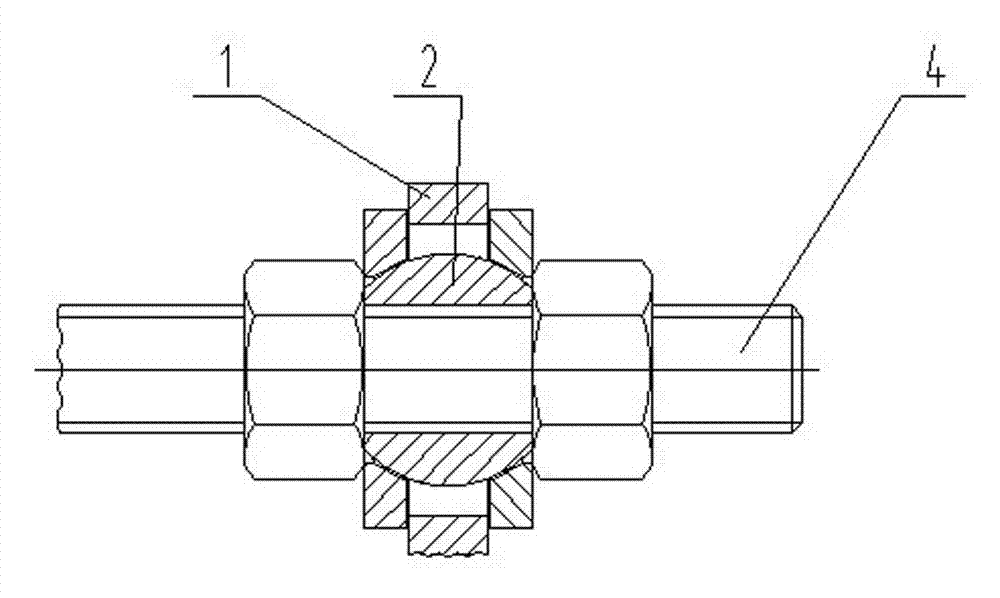

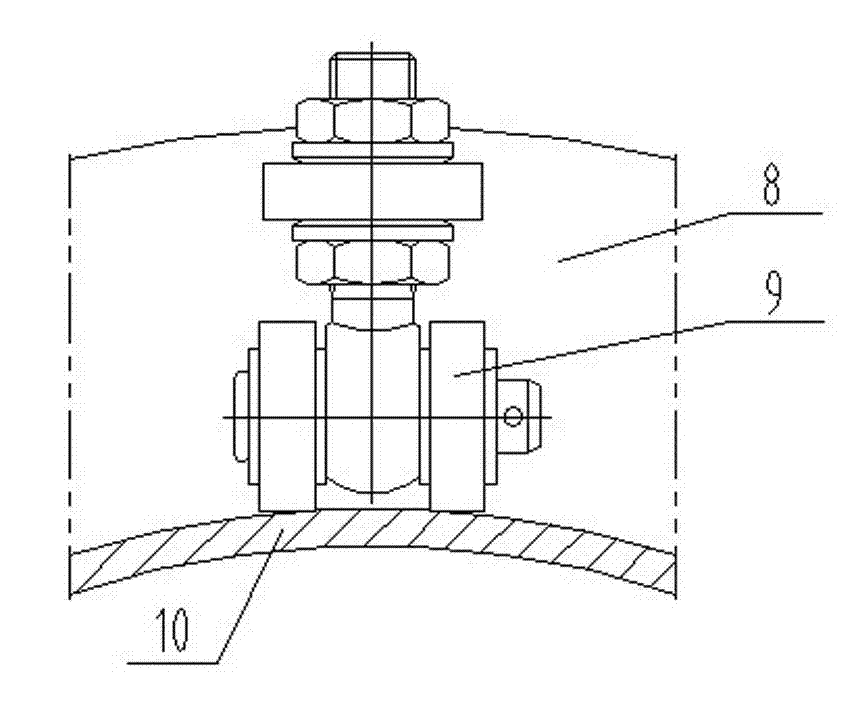

[0018] figure 1 Shown is an embodiment of a combined pulverized coal pipeline compensation device with a diameter of DN500mm, which is composed of a sleeve compensator in the center and a bellows compensator with the same diameter coaxially connected at both ends. The bellows compensator includes a bellows 3 in which two radial ring plates 1 are hermetically connected. On the same circumference of the radial ring plate 1 located at both ends of the bellows 3, 6 axial through holes are evenly distributed, and a ball seat 2 is installed in each axial through hole, and the double-ended screws 4 are connected in series and the ball seats at both ends are axially tightened 2 form a hinge connection. This structure directly limits the axial compensation of the bellows compensator, protects the bellows 3 from excessive deformation, and only uses the flexibility of the bellows 3 to abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com